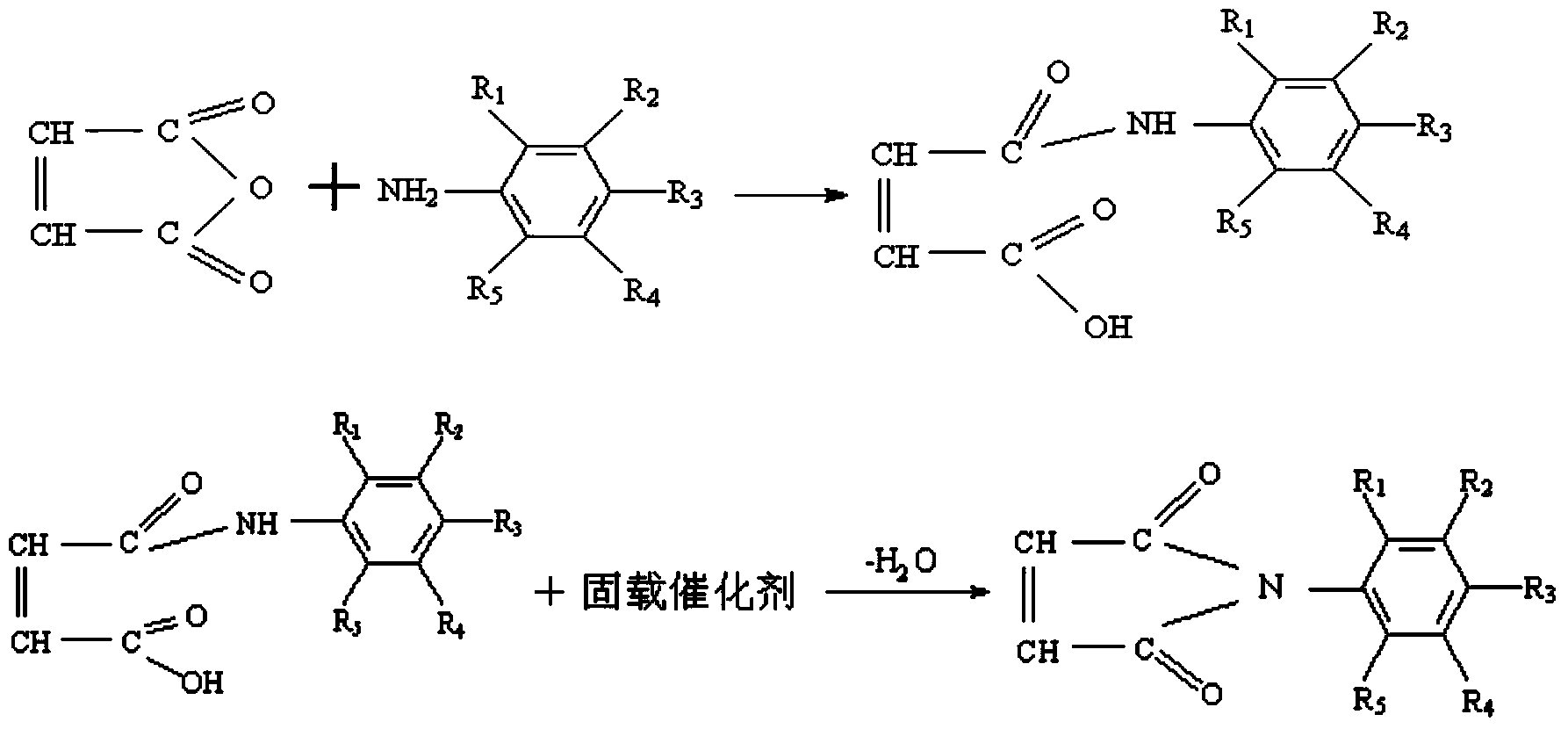

Immobilized type non-toxic catalyst and method for synthesizing N-phenylmaleimide and N-substitutional phenylmaleimide

A technology of maleimide and phenyl substitution, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. Large-scale production, unfavorable environmental protection and other issues, to achieve the effect of easy recycling, improve catalytic activity, and reduce equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A kind of preparation method of immobilized non-toxic catalyst, with 4A type zeolite molecular sieve carrier and zirconium organophosphine chelate aqueous solution as starting raw material, successively prepare through the following steps:

[0040] (1) In an environment of 20°C, dilute 40 parts of an aqueous solution of zirconium organophosphine chelate with a concentration of 50% zirconium organophosphine chelate by weight ratio through 60 parts of clean tap water to obtain a concentration of zirconium organophosphine chelate of 20% % impregnating liquid, 6g4A type zeolite molecular sieve carrier is added in 36g prepared impregnating liquid and impregnated for 7 hours, and reaction is bonded, wherein the mass ratio of 4A type zeolite molecular sieve carrier and zirconium organophosphine chelate aqueous solution is 1:6 ;

[0041] (2) Filter and dehydrate the impregnated 4A zeolite molecular sieve carrier, dry the filtered carrier in a constant temperature ...

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of immobilized non-toxic catalyst, with 4A type zeolite molecular sieve carrier and hafnium organophosphine chelate aqueous solution as starting raw material, successively prepare through following steps:

[0043] (1) In an environment of 30°C, dilute 45 parts of hafnium organophosphine chelate aqueous solution with a concentration of 50% hafnium organophosphine chelate by weight ratio through 55 parts of clean tap water to obtain a hafnium organophosphine chelate concentration of 25% Then, add the weighed 10g 4A type molecular sieve carrier into 50g of the prepared immersion liquid for immersion for 5 hours, and react to bond, wherein the mass ratio of the 4A type molecular sieve carrier to the immersion liquid is 1:5;

[0044] (2) Filter and dehydrate the impregnated 4A molecular sieve carrier, dry the filtrate in a constant temperature oven at 110°C for 4 hours, then place it in a muffle furnace, heat up to 450°C at a rate of...

Embodiment 3

[0045] Embodiment 3: A kind of preparation method of immobilized non-toxic catalyst, with 10X zeolite molecular sieve carrier and zirconium organophosphine chelate aqueous solution as starting raw material, successively prepare through the following steps:

[0046] (1) At 25°C, select 50g of zirconium organophosphine chelate aqueous solution with a zirconium organophosphine chelate concentration of 50% as the impregnation solution, and then add 5g of 10X zeolite molecular sieve carrier weighed into the prepared impregnation solution Immersed in medium for 6 hours, reaction bonding, wherein the mass ratio of 10X zeolite molecular sieve carrier to impregnating liquid is 1:10;

[0047] (2) Filter and dehydrate the impregnated 10X zeolite molecular sieve carrier, dry the filtered carrier in a constant temperature oven at 60°C for 6 hours, then place it in a muffle furnace, raise the temperature to 300°C at a rate of 5°C / s, and roast for 6 hours , to obtain a solid-supported non-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com