Free flow electrophoresis chip of adhesive tape and processing method thereof

An electrophoretic chip and processing method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve problems such as the collapse of the separation area of the electrophoretic chip, increase the difficulty of separation operation, and difficulty in entering liquid, and achieve Low cost, good transparency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

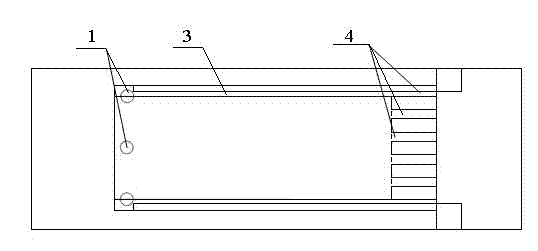

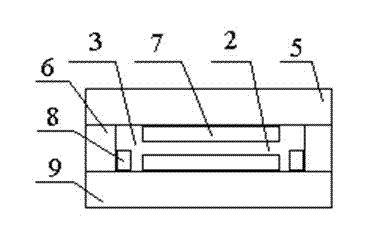

[0025] Such as figure 1 and 2 Shown, the adhesive tape free-flow electrophoresis chip of double-step equal height of the present embodiment, it is made up of upper substrate 5, lower substrate 9, intermediate structure layer and electrode 8, and described intermediate structure layer is made up of upper substrate 5 and The lower substrate 9 is bonded together by a patterned double-sided adhesive tape 6 to form a fluid cavity, the cavity is provided with a liquid outlet 4, and the upper substrate 5 is provided with a liquid inlet 1 communicating with the cavity. The area between the upper substrate 5 and the lower substrate 9 corresponding to the wall surface pasted with the single-sided adhesive tape 7 is the separation chamber 2, and the two sides of the separation chamber 2 are electrolytic cells 3, and electrodes 8 are installed in the electrode cell 3 and beside the cavity side wall. The liquid flowing in from the liquid inlet hole 1 flows out from the liquid outlet 4 on ...

Embodiment 2

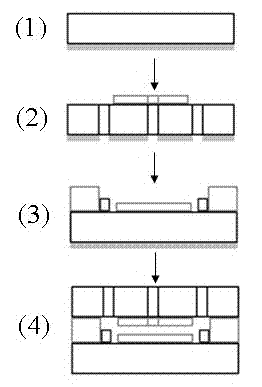

[0035] This embodiment is a tape free-flow electrophoresis chip with double steps and unequal heights, which consists of an upper substrate, a lower substrate, an intermediate structural layer and electrodes. The specific process is as follows:

[0036] 1. The upper and lower substrates are carrier films, and the single-sided and double-sided tapes are KAPTON tapes produced by Yimai Technology. The specifications of the single-sided tapes are 65 and 125 μm respectively, and the specifications of the double-sided tapes are 125 μm; the electrodes are aluminum film tapes.

[0037] 2. Print the chip structure graphics and paste them on the cleaned upper and lower substrates respectively as alignment marks.

[0038] 3. Upper substrate processing: ①Use an ultrasonic vibrator to drill the liquid inlet hole on the carrier film, use a glass knife to cut off the excess part of the carrier film, ②clean the surface, and ③use a carving knife to carve a 65μm thick monolith according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com