Soft magnetic iron powder core manufactured by aluminum coated oxidation method

A technology of aluminum cladding and soft magnets, applied in the direction of the magnetism of inorganic materials, can solve the problems of low silicon and aluminum content, the inability to form oxide films, high hysteresis loss of iron powder cores, and difficulty in forming insulating layers, etc., to achieve increased density and improved Effects of magnetic permeability and eddy current loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention is further described

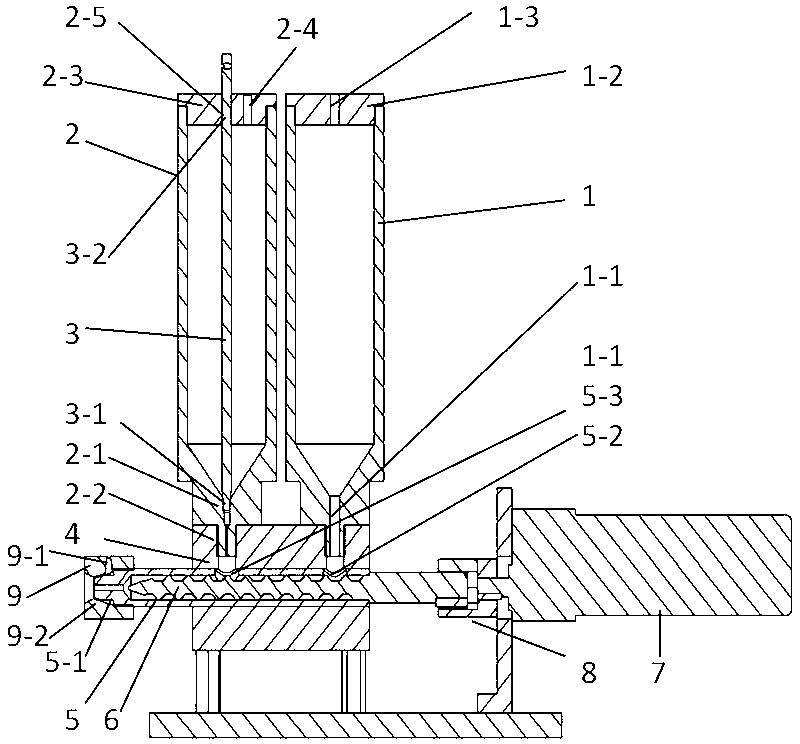

[0010] figure 1 Diagram of the device for manufacturing aluminum cladding layer by solid-liquid mixing and gas blowing method;

[0011] In the figure 1. Fe-based soft magnetic powder heating barrel, 1-1. Soft magnetic powder channel, 1-2. Soft magnetic powder barrel sealing cover, 1-3. Soft magnetic powder barrel atmosphere hole, 2. Aluminum melting Barrel, 2-1. Needle valve seat, 2-2. Bottom channel of aluminum barrel, 2-3. Sealing cover of aluminum barrel, 2-4. Atmosphere hole of aluminum barrel, 2-5. Lifting threaded hole, 3 .Needle valve (3), 3-1. Needle valve conical head (3-1), 3-2. Lifting thread, 4. Screw base, 5. Screw sleeve, 5-1. Powder nozzle, 5- 2. Soft magnetic powder inlet, 5-3. Aluminum liquid inlet, 6. Screw, 7. Motor, 8. Coupling, 9. Gas blowing head, 9-1. Blowing inlet, 9-2 . Annular gas nozzle.

[0012] figure 1 Explains the process of soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com