Anode treatment method of aluminium alloy

A technology of anodizing, aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

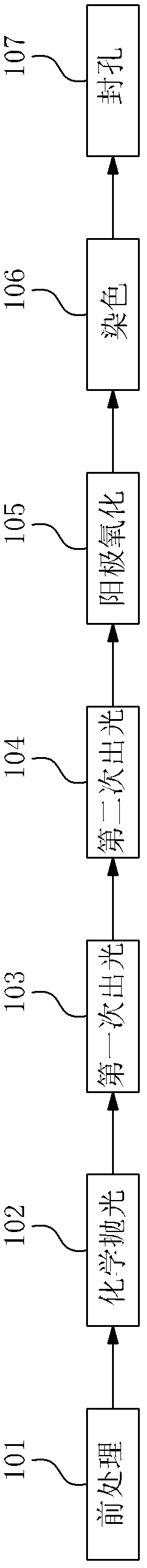

[0026] see figure 1 As shown, it depicts a flow chart of the steps of the aluminum alloy anodic treatment method of the present invention.

[0027] In the first embodiment of the present invention, the aluminum alloy anodic treatment method of the present invention comprises the following steps:

[0028] Step 101: Sandblasting the ADC6 aluminum alloy die-casting to make the appearance change uniformly and achieve the purpose of appearance decoration; then put it into the degreasing tank for degreasing treatment to remove or soften the surface grease, and use acid degreasing agent for degreasing Sulfuric acid, the concentration of this sulfuric acid is 15wt%; Carry out alkali washing after washing, remove surface passivation coating, the surface can produce black powder scale, alkali washing solvent is sodium hydroxide solution, and its concentration is 15wt%;

[0029] Step 102: In order to increase its brightness, the above-mentioned aluminum alloy die-casting is washed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com