Method for preparing ginsenoside Rd by utilizing microbial conversion

A microbial transformation and ginsenoside technology, applied in the field of biomedicine, can solve the problems of single acquisition channel, low content, complex structure, etc., and achieve the effect of expanding the source of drug resources, simple process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

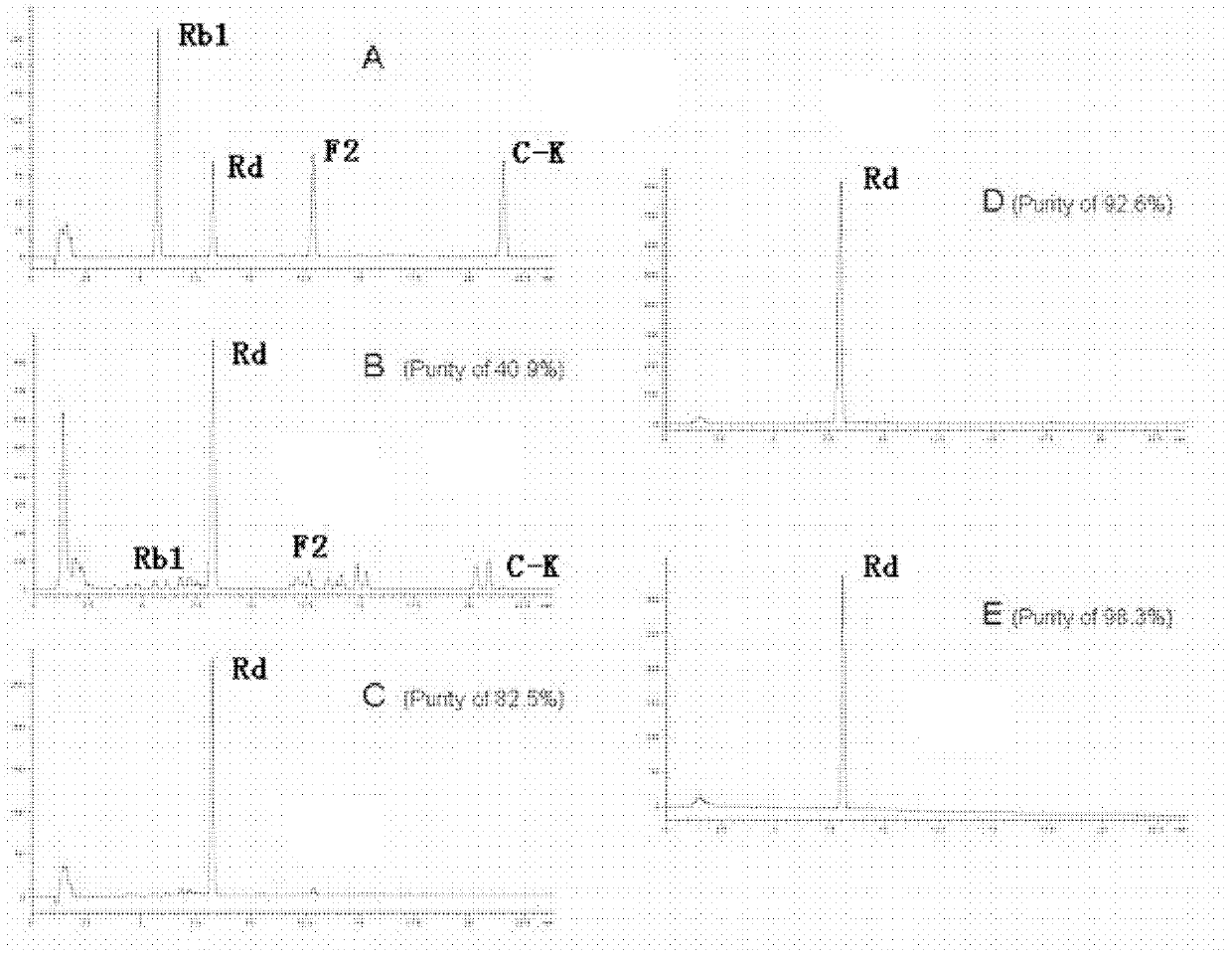

[0044] Example 1 strain screening

[0045] Purchase 50 strains of different strains from the Industrial Microbiology Collection Center of China Microbiological Culture Collection Management Committee, and use the following shake flask process to screen:

[0046] Fermentation medium: 3% sucrose, 3% soybean flour, 0.1% ammonium sulfate, 0.1% magnesium sulfate, 0.1% calcium chloride, 0.5% bran. All culture media were packed in 250ml Erlenmeyer flasks with a volume of 30ml, and sterilized at 121°C for 20min. Inoculate from potato slant, culture on shaker at 28°C and 250rpm for 24h, add 5% ginsenoside Rb1, and continue to cultivate for 48h. After the fermentation is over, an equal volume of ethanol is added for extraction. Through HPLC analysis, it is determined that Aspergillus niger with strain preservation number CICC40426 is the bacterial strain for preparing ginsenoside Rd through microbial transformation of the present invention, and it has the best conversion rate, which c...

example 2

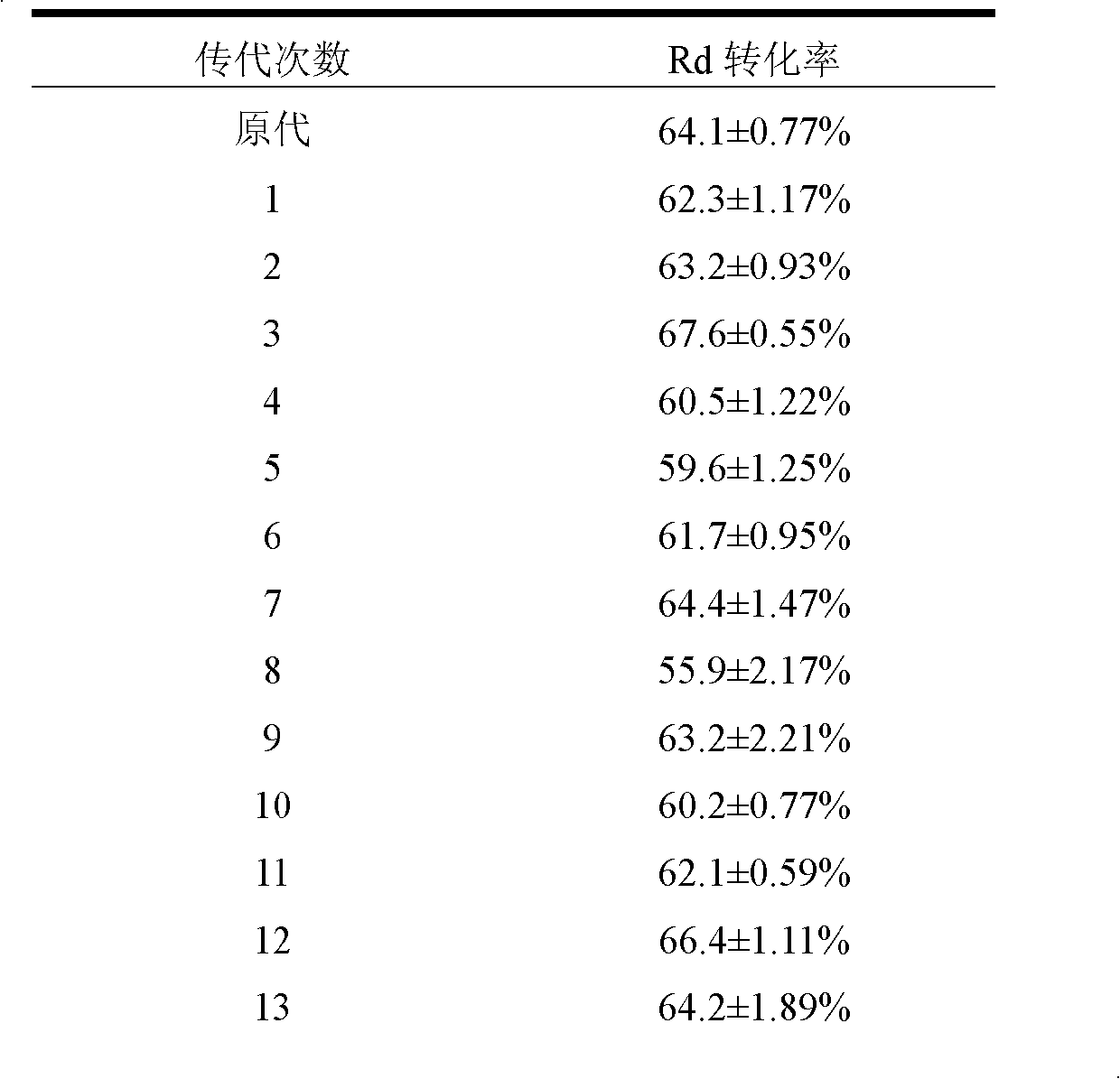

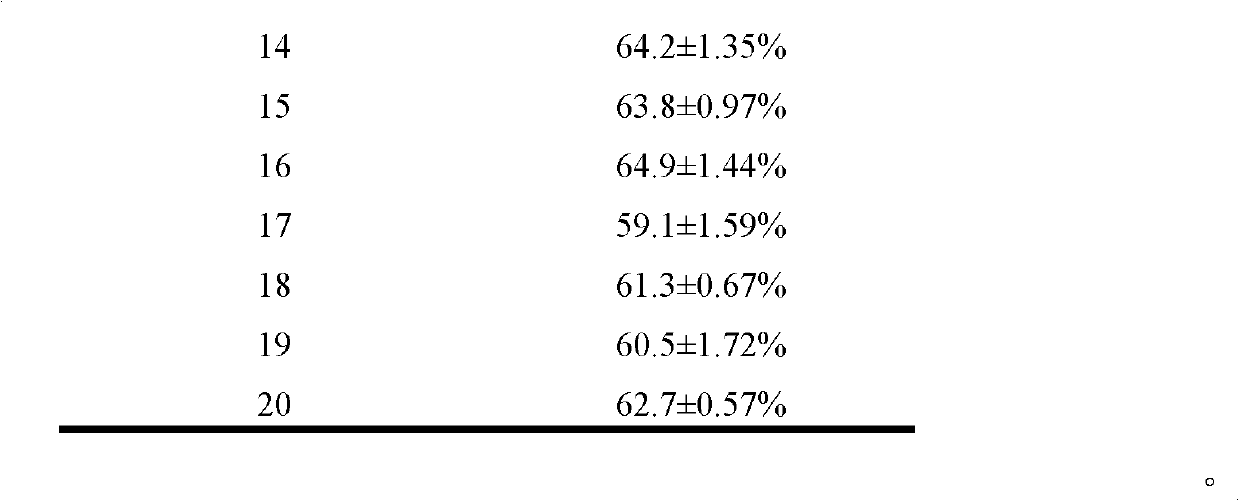

[0047] Example 2 passage test

[0048] Using the fermentation method of Example 1, ferment the Aspergillus niger whose strain preservation number is CICC40426, and carry out the passage test. The results are shown in Table 1. After 20 generations of passage, the Rd conversion rate of the strain is still very stable.

[0049] Table 1 Passage results

[0050]

[0051]

example 3

[0052] The optimization of example 3 culture medium

[0053] Using the fermentation method of Example 1, ferment the Aspergillus niger with the strain preservation number CICC40426, optimize the medium, and optimize the carbon source: glucose, sucrose, maltose, lactose, potato, starch, and bran were respectively investigated as carbon sources. , the influence on the conversion rate of Rd. Results When bran, glucose, sucrose and starch were used as carbon sources, the conversion rate of Rd was higher. Delayed nitrogen source: The effects of corn steep liquor, cottonseed powder, yeast powder, soybean powder, peptone and peanut powder on the conversion rate of Rd were investigated respectively as delayed nitrogen sources. Results When yeast powder, soybean powder and peptone were used as nitrogen sources, the conversion rate of Rd was higher. On this basis, statistical methods are used to comprehensively investigate the effects of carbon sources, nitrogen sources, trace element...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com