Modified nylon 1012 powder coating and preparation method thereof

A technology for modifying nylon and powder coatings, applied in powder coatings, polyamide coatings, coatings, etc., can solve the problems of unfavorable thermal spraying construction, high melting point, ensure the controllability of yield and particle size, simple preparation process, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

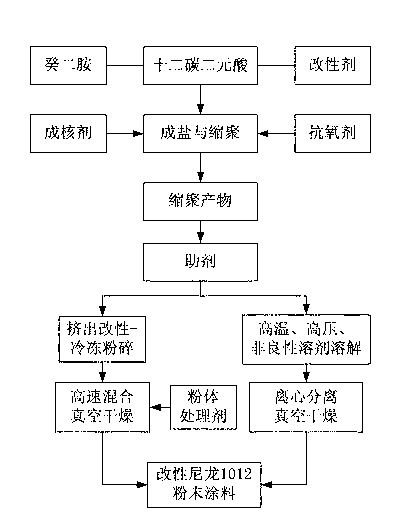

Method used

Image

Examples

Embodiment 1

[0037] Modified nylon 1012 powder coating of the present invention and preparation method thereof, its steps are as follows:

[0038] Step 1: Put 40% decanediamine, 54% dodecanedibasic acid, and 6% nylon 66 salt into the autoclave, add decanedidiamine, dodecanedibasic acid and modifier Demineralized water with a mass of 50% is heated by electricity, stirring is started, the temperature of the material is controlled at 80°C, the pH value is 7.0-7.2, and the temperature is kept for 1 hour to pre-form salt.

[0039] Step 2: Add 0.1% phosphorous acid, 0.4% antioxidant 1098, and 0.1% fumed silica, seal the autoclave, replace the air in the autoclave twice with carbon dioxide, turn on the electricity for heating, and start stirring. When the pressure reaches 1.2Mpa and the temperature of the material reaches 200°C, heat preservation and pressure maintenance are started for 2 hours, and then the pressure is uniformly reduced to normal pressure within 2 hours, and the heat preservatio...

Embodiment 2

[0042] Modified nylon 1012 powder coating of the present invention and preparation method thereof, its steps are as follows:

[0043] Step 1: put 25% decanediamine, 35% dodecanedibasic acid, and 40% nylon 612 salt into the autoclave, add decanedidiamine, dodecanedibasic acid and modifier Demineralized water with a mass of 400% is heated by electricity, stirring is started, the temperature of the material is controlled at 85°C, the pH value is 7.0-7.2, and the temperature is kept for 0.5 hours to pre-salt.

[0044] Step 2: Add 0.3% phosphorous acid and 0.5% magnesium oxide, seal the autoclave, replace the air in the autoclave with carbon dioxide twice, turn on the electricity for heating, and start stirring. When the pressure reaches 1.2Mpa and the temperature of the material reaches 210°C, heat preservation and pressure maintenance are started for 2 hours, and then the pressure is uniformly reduced to normal pressure within 2 hours, and the heat preservation is continued for 1...

Embodiment 3

[0047] Modified nylon 1012 powder coating of the present invention and preparation method thereof, its steps are as follows:

[0048] Step 1: Put 40% decanediamine, 54% dodecanedibasic acid, and 6% modifier (2.7% hexamethylenediamine and 3.3% adipic acid) into the autoclave, and add decanedidioic acid Demineralized water with 60% of the total mass of amine, dodecanedibasic acid and modifier is heated by electricity, stirring is started, the temperature of the material is controlled at 80°C, the pH value is 7.0-7.2, and the temperature is kept for 1 hour to pre-salt.

[0049] Step 2: Add 0.1% phosphorous acid, 0.4% antioxidant 1098, and 0.3% magnesium oxide, seal the autoclave, replace the air in the autoclave twice with carbon dioxide, turn on the electricity for heating, and start stirring. When the pressure reaches 1.2Mpa and the temperature of the material reaches 200°C, heat preservation and pressure maintenance are started for 2 hours, and then the pressure is uniformly r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com