Mask conveying box and method for reducing mask pollution

A technology of mask plate and transfer box, which is applied in the field of mask plate contaminated by particles during use and transmission, mask plate transfer box, which can solve the problems of mask plate change, influence on exposure, imaging, etc., and reduce the secondary The probability of secondary pollution, the effect of improving cleanliness and reducing particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

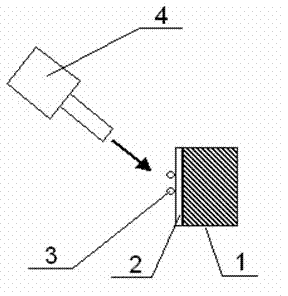

[0021] The present invention provides a mask plate transfer box and a method for reducing mask plate pollution. In the prior art, people often cover the mask plate with a protective film so that the micro particles will not directly fall into the pattern area. There is a height difference of about 5mm between the surface of the protective film and the graphic area to reduce contamination of the mask. However, the inventor found through research that a lot of pollution particles did not fall on the mask at first, but on the inner surface of the transfer box, and fell on the surface of the mask during the transfer process, causing secondary pollution.

[0022] In view of this situation, the mask transfer box provided by the present invention is coated with an adhesive layer on the inner surface of the box cover, which can effectively capture free pollutants. On the one hand, the cleanliness of the mask transfer box itself is improved. On the one hand, it purifies the environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com