Synthesis and purification method of electronic grade arsines

A purification method and electronic-grade technology, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of low adsorption efficiency, difficulty in obtaining heavy metals, high system cost, etc., and achieve high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

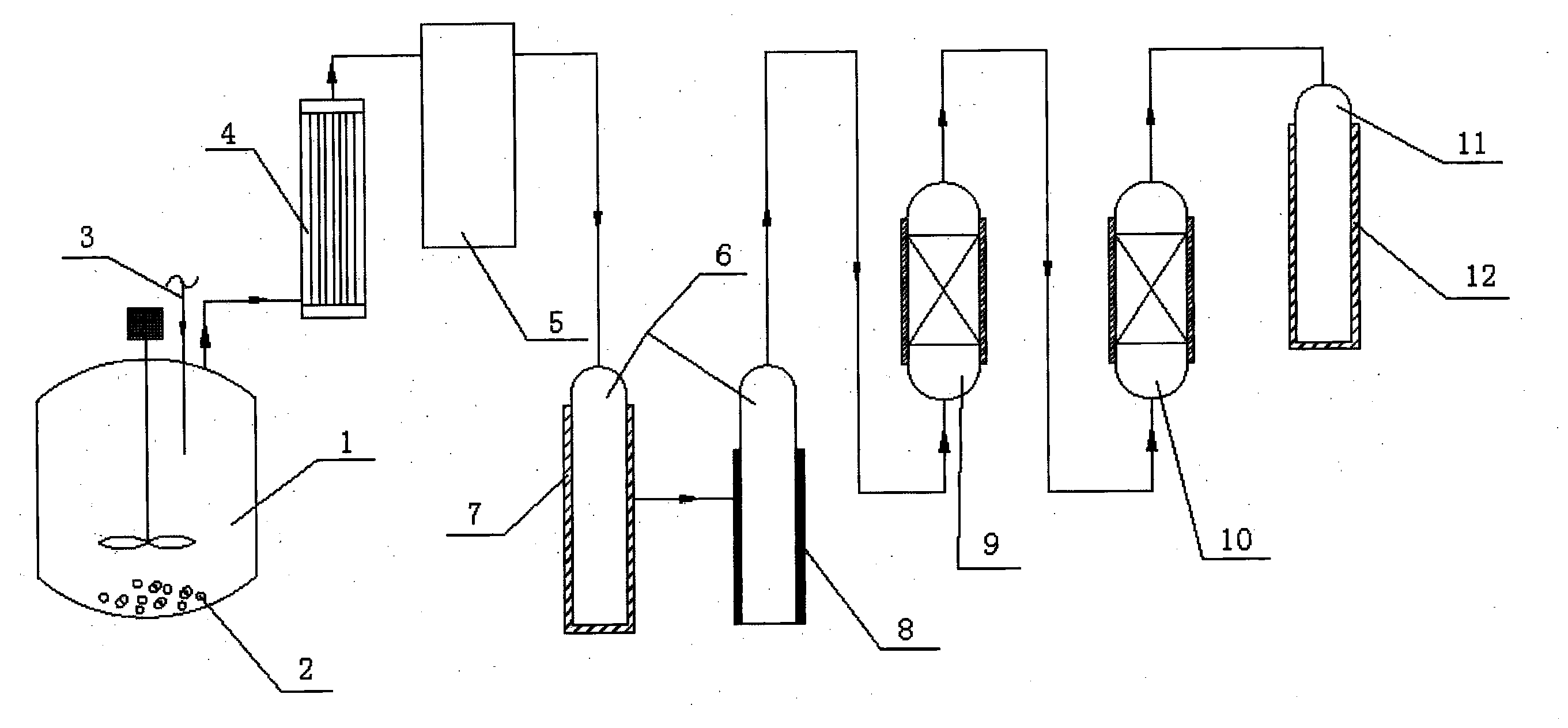

[0032] As shown in Figure 1, it is a flowchart of the synthesis and purification method of a kind of electronic grade arsine provided by the present invention, and the specific steps are as follows:

[0033] Step S1: Weigh 3.46g of zinc arsenide powder 2 into the reactor 1, seal it and evacuate it, slowly add 9.2ml of dilute sulfuric acid with a mass concentration of 30% from the feed port 3 until no bubbles are generated in the solution, Whole reaction is carried out under vacuum state;

[0034] Step S2: the crude arsine gas generated in step S1 passes through the condenser 4, and the condensation temperature is -30°C, so that the liquid droplets in the gas are separated;

[0035] Step S3: the crude arsine gas produced in step S2 passes through an adsorption trap 5 equipped with desiccant and carbon dioxide adsorbent to remove most of the water and carbon dioxide, and the desiccant and carbon dioxide adsorbent can be recycled;

[0036] Step S4: Pass the crude arsine obtained...

Embodiment 2

[0043] As shown in Figure 1, it is a flowchart of the synthesis and purification method of a kind of electronic grade arsine provided by the present invention, and the specific steps are as follows:

[0044] Step S1: Weigh 6.23g of zinc arsenide powder 2 into the reactor 1, seal it and evacuate it, and slowly add 6.4ml of dilute sulfuric acid with a mass concentration of 50% from the feed port 3 until no bubbles are generated in the solution. Whole reaction is carried out under vacuum state;

[0045] Step S2: the crude arsine gas generated in step S1 passes through the condenser 4, and the condensation temperature is 0°C, so that the liquid droplets in the gas are separated;

[0046] Step S3: the crude arsine gas produced in step S2 passes through an adsorption trap 5 equipped with desiccant and carbon dioxide adsorbent to remove most of the water and carbon dioxide, and the desiccant and carbon dioxide adsorbent can be recycled;

[0047] Step S4: Pass the crude arsine obtain...

Embodiment 3

[0054] As shown in Figure 1, it is a flowchart of the synthesis and purification method of a kind of electronic grade arsine provided by the present invention, and the specific steps are as follows:

[0055] Step S1: Weigh 4.15g of zinc arsenide powder 2 into the reactor 1, seal it and evacuate it, and slowly add 17.2ml of dilute sulfuric acid with a mass concentration of 10% from the feed port 3 until no bubbles are generated in the solution, Whole reaction is carried out under vacuum state;

[0056] Step S2: the crude arsine gas generated in step S1 passes through the condenser 4, and the condensation temperature is -40°C, so that the liquid droplets in the gas are separated;

[0057] Step S3: the crude arsine gas produced in step S2 passes through an adsorption trap 5 equipped with desiccant and carbon dioxide adsorbent to remove most of the water and carbon dioxide, and the desiccant and carbon dioxide adsorbent can be recycled;

[0058] Step S4: Pass the crude arsine obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com