Combined mineral processing technology of low-grade laterite type weathering titanium placers

A titanium placer, low-grade technology, applied in the field of low-grade laterite type weathered titanium placer combined beneficiation process, can solve the problems of resource waste, abandonment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

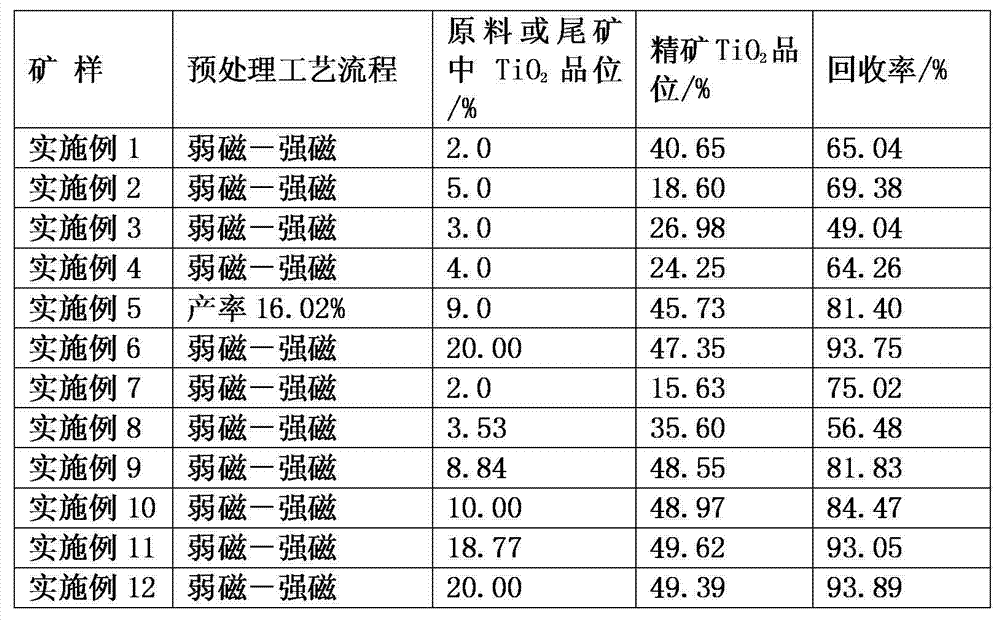

Examples

Embodiment 1

[0023] Embodiment 1: (Take tailings with a titanium dioxide content of 2.0% as raw material)

[0024] (1) Raw material preparation: use tailings with a titanium dioxide content of 2.0% after being processed by other beneficiation methods as raw materials; after adding water, after conventional stirring or grinding, the obtained fineness is 1-0.037mm;

[0025] (2) Weak magnetic separation: the pulp is in the magnetic separator, using wet weak magnetic separation process, wherein when the strength of the weak magnetic field is 0.05T, the obtained iron concentrate has an iron content of 15-70% and a titanium dioxide content of 5 ~30%; and the content of titanium dioxide in weak magnetic tailings is 5~40%;

[0026] (3) Strong magnetic separation: The weak magnetic tailings obtained in step (2) are subjected to strong magnetic separation treatment. When the strength of the strong magnetic field is 0.3T, the titanium dioxide content of titanium rough concentrate is 15-45 % and the ...

Embodiment 2

[0029] Embodiment 2: (take tailings with a titanium dioxide content of 5.0% as raw material)

[0030] Processing step is identical with embodiment 1, to containing TiO 2 After stirring or grinding 5.0% of the tailings, the selected particle size is -0.45mm; adopt the "weak magnetic-strong magnetic" beneficiation process to obtain titanium rough concentrate; the strength of the weak magnetic field is 0.2T; the strength of the strong magnetic field is 1.1 T, the yield of titanium rough concentrate is 18.60%, the content of titanium dioxide is 18.60%, and the recovery rate is 69.38%.

Embodiment 3

[0031] Embodiment 3: (Take tailings with a titanium dioxide content of 3.0% as raw material)

[0032] Processing step is identical with embodiment 1, to containing TiO 2 After 3.0% of the tailings are stirred or ground, the selected particle size is -0.45mm; the "weak magnetic - strong magnetic" beneficiation process is used to obtain titanium rough concentrate; the strength of the weak magnetic field is 0.13T; the strength of the strong magnetic field is 1.0 T, the yield of titanium rough concentrate is 4.60%, the content of titanium dioxide is 26.98%, and the recovery rate is 49.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com