Polyol for polyurethane preparation and polyurethane preparation method using same

A technology of polyol and polyurethane, which is applied in the field of polyol, can solve the problems of decreased foam hardness, insufficient mechanical properties such as elongation and tensile strength of soft polyurethane foam, and achieves improved mechanical properties and good hardness of polyurethane Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0203] Production example 1 [production of polyol a-1]

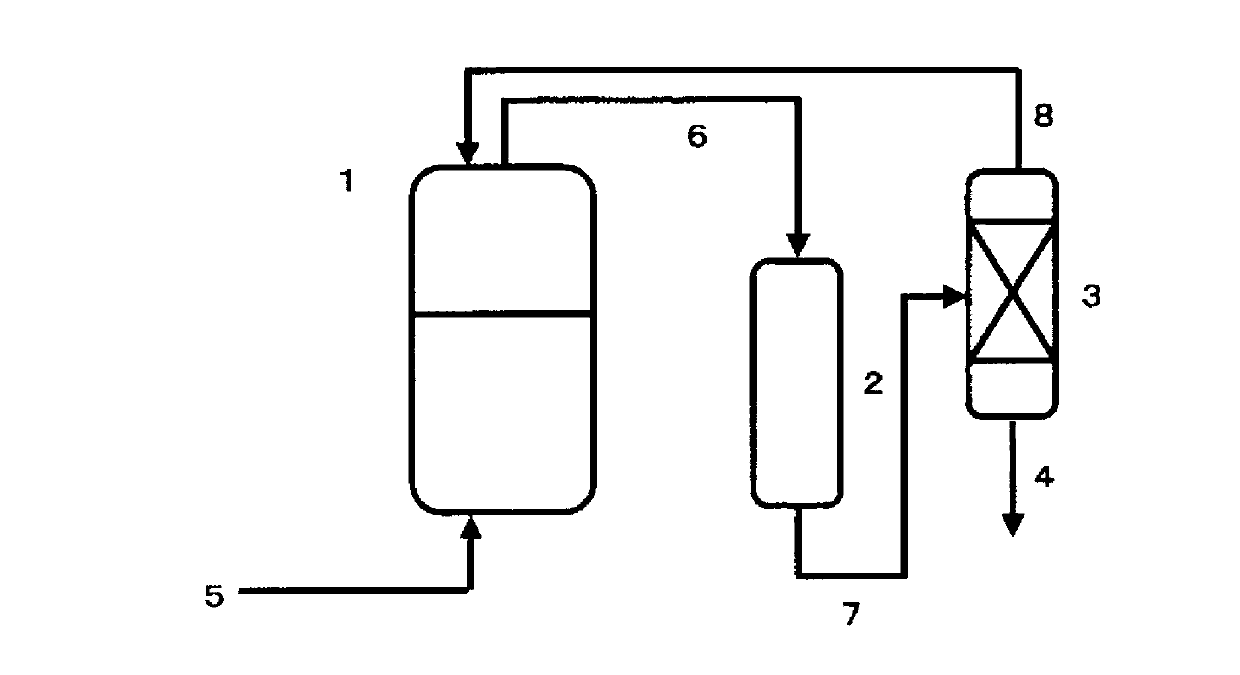

[0204] like figure 1As shown, using circulation lines (6), (7), and (8), a stainless steel autoclave with a capacity of 2500 ml, equipped with a stirring device, a temperature control device, and a raw material supply line (5) as a reaction tank (1) and Reaction tower (2) filled with 400 parts of magnesium oxide (particles, 2-0.1 mm in diameter) (using two stainless steel cylindrical tubes with an inner diameter of 5.5 cm and a length of 30 cm) and distillation tower (3) (theoretical tower The number of plates is 30 sections, and the stainless steel cylindrical tube with an inner diameter of 5.5cm and a length of 2m) is connected.

[0205] After putting 400 g of PO adduct (hydroxyl value 280) of glycerol and 0.09 g of tris(pentafluorophenyl) borane into the reaction tank (1), the autoclave {reaction tank (1)} and the reaction tower ( 2) and circulation pipelines (6), (7), (8) depressurize to 0.005MPa. While controllin...

manufacture example 2

[0207] Production example 2 [production of polyol a-2]

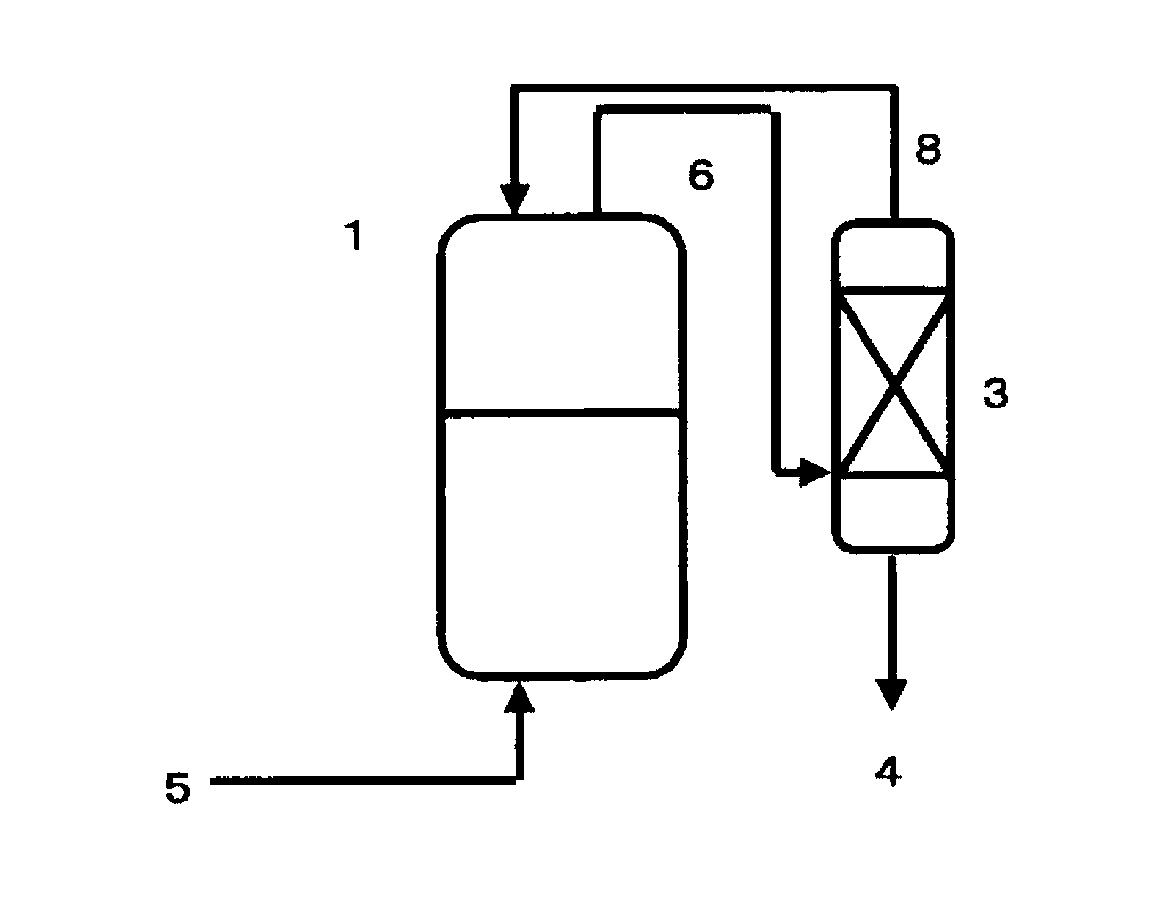

[0208] like figure 2 As shown, using circulation lines (6) and (8), a stainless steel autoclave with a capacity of 2500 ml, a stirring device, a temperature control device, and a raw material supply line (5) as a reaction tank (1) and a distillation column (3 ) (theoretical plate number is 50 sections, stainless steel cylindrical tube, inner diameter is 5.5cm, length is 3m) connection.

[0209] After putting 400 g of PO adduct (hydroxyl value 280) of glycerol and 0.09 g of tris(pentafluorophenyl) borane into the reaction tank (1), the autoclave {reaction tank (1)} and the reaction tower ( 2) and circulation pipelines (6), (8) depressurize to 0.005MPa. While controlling the reaction temperature to keep it at 50-60°C, continuously inject PO into the liquid phase through the raw material supply pipeline (5), and use a diaphragm pump to make the gas phase in the reaction tank (1) flow at a flow rate of 5L / min. Circulate ...

manufacture example 3

[0211] Production example 3 [production of polyol a-3]

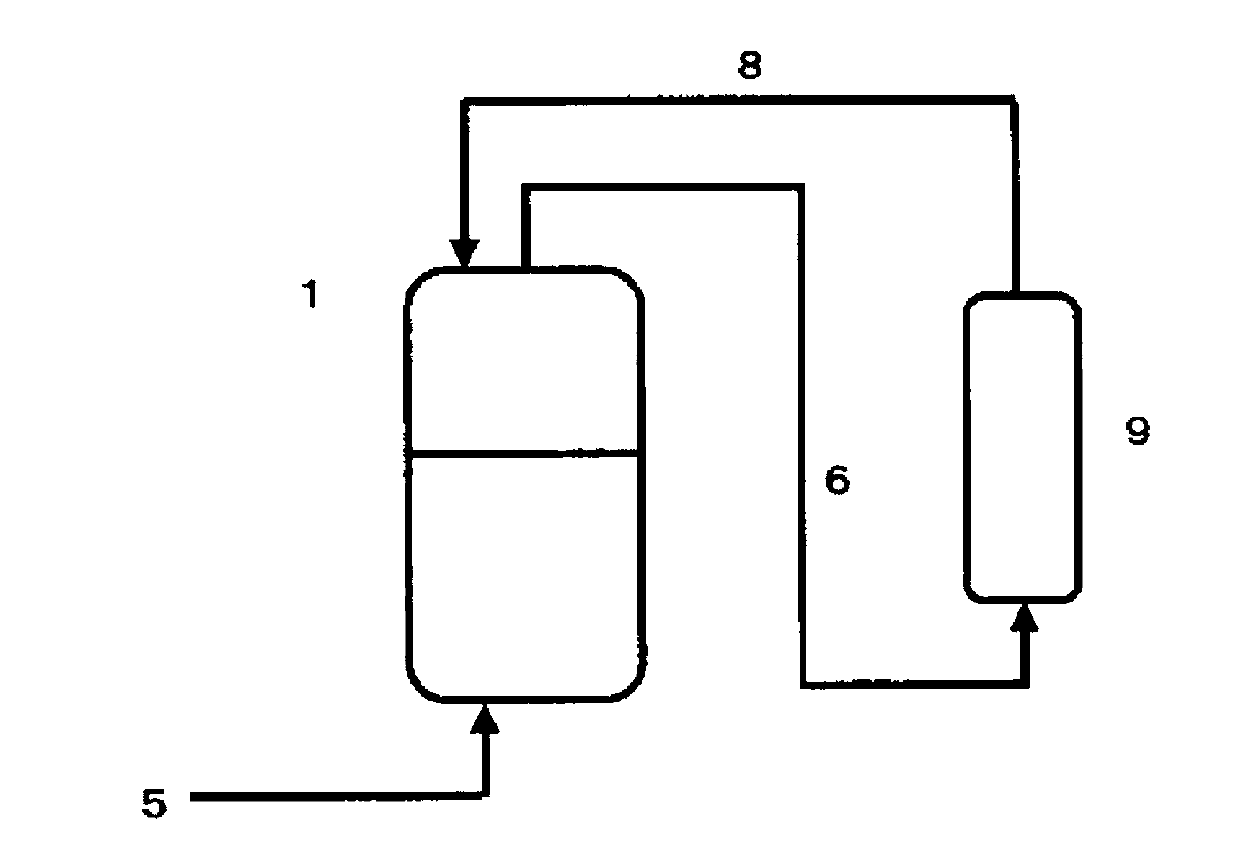

[0212] like image 3 As shown, using the circulation lines (6) and (8), a 2500ml stainless steel autoclave with a stirring device, a temperature control device, and a raw material supply line (5) as a reaction tank (1) was filled with 500 parts of molecular sieves The adsorption tower (9) of 4A (stainless steel cylindrical pipe, internal diameter is 5.5cm, and length is 30cm) is connected.

[0213] After putting in 400g of PO adduct (hydroxyl value 280) of glycerol and 0.09g of tris(pentafluorophenyl)borane, connect the autoclave {reaction tank (1)} with the adsorption tower (9) and pipeline (6) , (8) The internal pressure is reduced to 0.005MPa. While controlling the reaction temperature to keep it at 50-60°C, continuously feed PO through the raw material supply pipeline (5), and use a diaphragm pump to make the gas phase in the reaction tank (1) flow in the reaction tank (1) at a flow rate of 5 L / min. )→Decompressio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com