Bio-ink composition for 3D printing, containing human-derived component and having tissue-specific cell differentiation effect, and preparation method therefor

A bio-ink and 3D printing technology, applied in applications, inks, household appliances, etc., to achieve high cell affinity and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0078] Hereinafter, the present invention will be described more specifically by way of examples. However, the scope of the present invention is not limited to the following examples, and those skilled in the art should understand that various variations, modifications, or applications can be made within the scope of the technical idea derived from the contents of the claims.

Embodiment 1

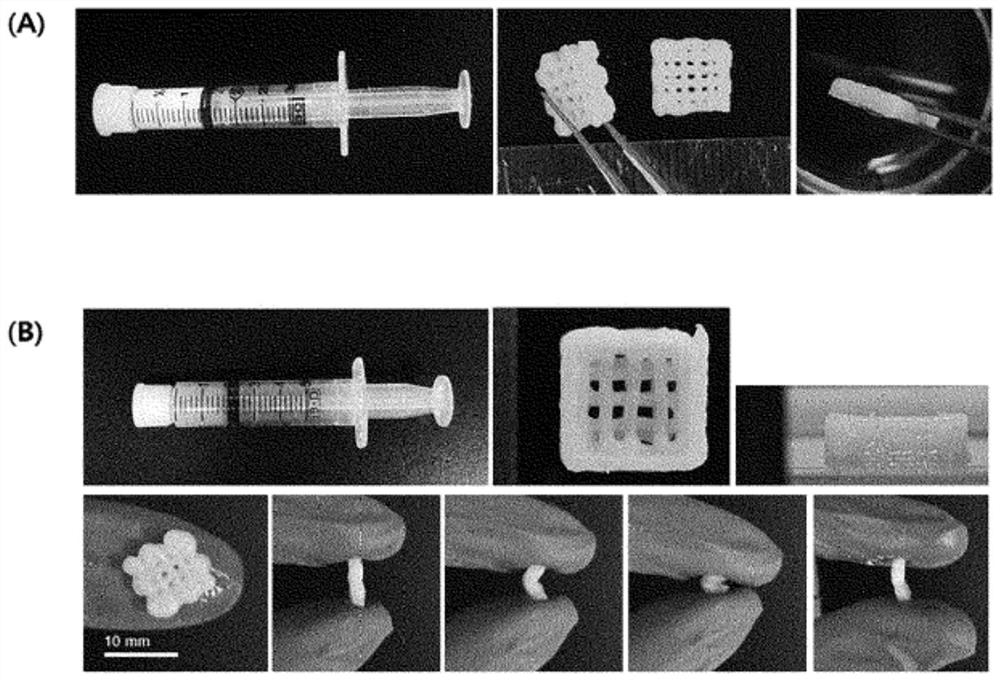

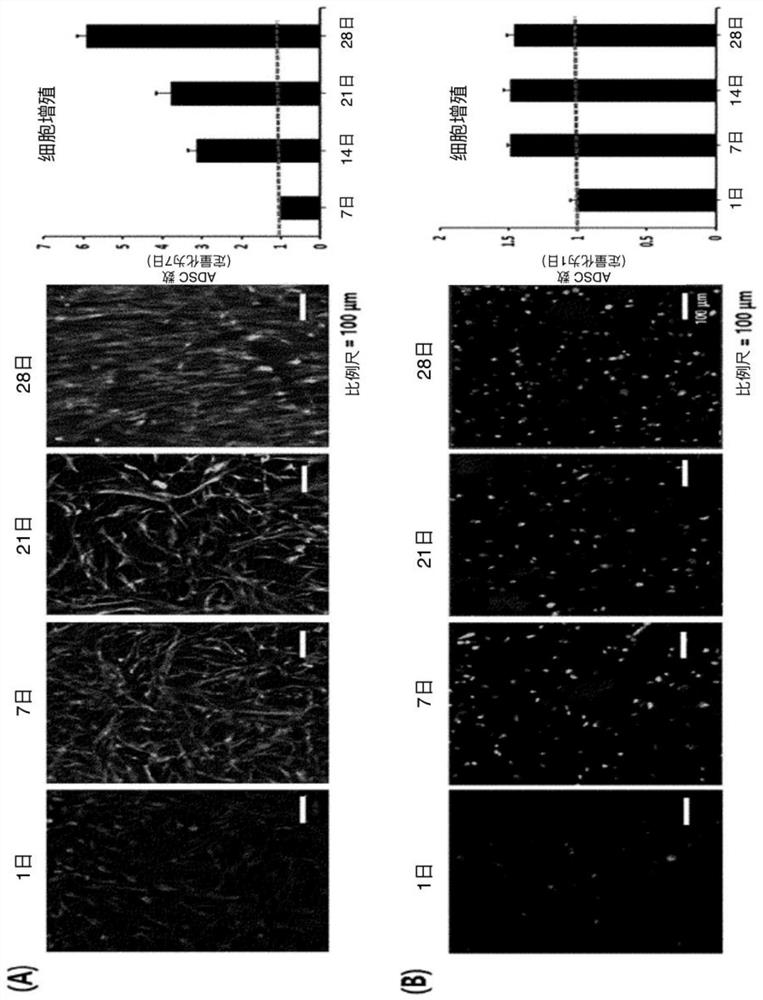

[0080] Example 1: Fabrication of bioinks comprising micronized acellular dermal matrix (Micronized Acellular Dermal Matrix, M-ADM) tissue

[0081] (1) Manufacture of M-ADM powder

[0082] Decellularized skin tissue (collected from cadavers donated by tissue banks for non-profit patient treatment).

[0083] First, the skin tissue is subjected to a degreasing process using alcohol and hexane. Thereafter, the epidermis and cells were removed using sodium hydroxide (NaOH), and the 2 S) Remove the hair sticking to the tissue. Then, after hydrogen peroxide (H 2 o 2 ) and then neutralized and washed with distilled water. The washed skin tissue was freeze-dried to remove water, and the tissue was pulverized using a micro pulverizer. In the pulverization, a dermal tissue powder of 500 μm or less is produced by passing through a sieve with a diameter of 250-500 μm.

[0084] The prepared tissue in powder form is sterilized.

[0085] (2) Manufacture of M-ADM-based bioink

[0086]...

Embodiment 2

[0090] Example 2: Fabrication of bioinks comprising micronized acellular cartilage (M-AC) tissue

[0091] (1) Manufacture of M-AC powder

[0092] Cartilage tissue (collected from cadavers donated from tissue banks for non-profit patient treatment) was pulverized using a micro-pulverizer. In the crushing, the cartilage tissue powder below 500 um is obtained through a sieve with a diameter of 250-500 um.

[0093] Thereafter, decellularization was performed after obtaining cartilage tissue powder.

[0094] First, a degreasing process is performed on the cartilage tissue using alcohol and hexane. Thereafter, cells were removed with sodium hydroxide (NaOH), and washed with ethanol (Ethanol) and distilled water. After removing water by freeze-drying, the tissue in powder form is sterilized with an electron beam.

[0095] (2) Fabrication of M-AC-based bioink

[0096] The M-AC powder prepared in (1) and the alginate aqueous solution were mixed to prepare a bioink composition in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com