Method for directly plating plastic with drawn wire appearance

A metal wire drawing and appearance technology, applied in the field of plastic electroplating technology, can solve the problems of high substrate surface requirements, large amount of metal consumption, high water and energy consumption, etc., to achieve strong metal texture, high yield rate, and save nickel plating the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

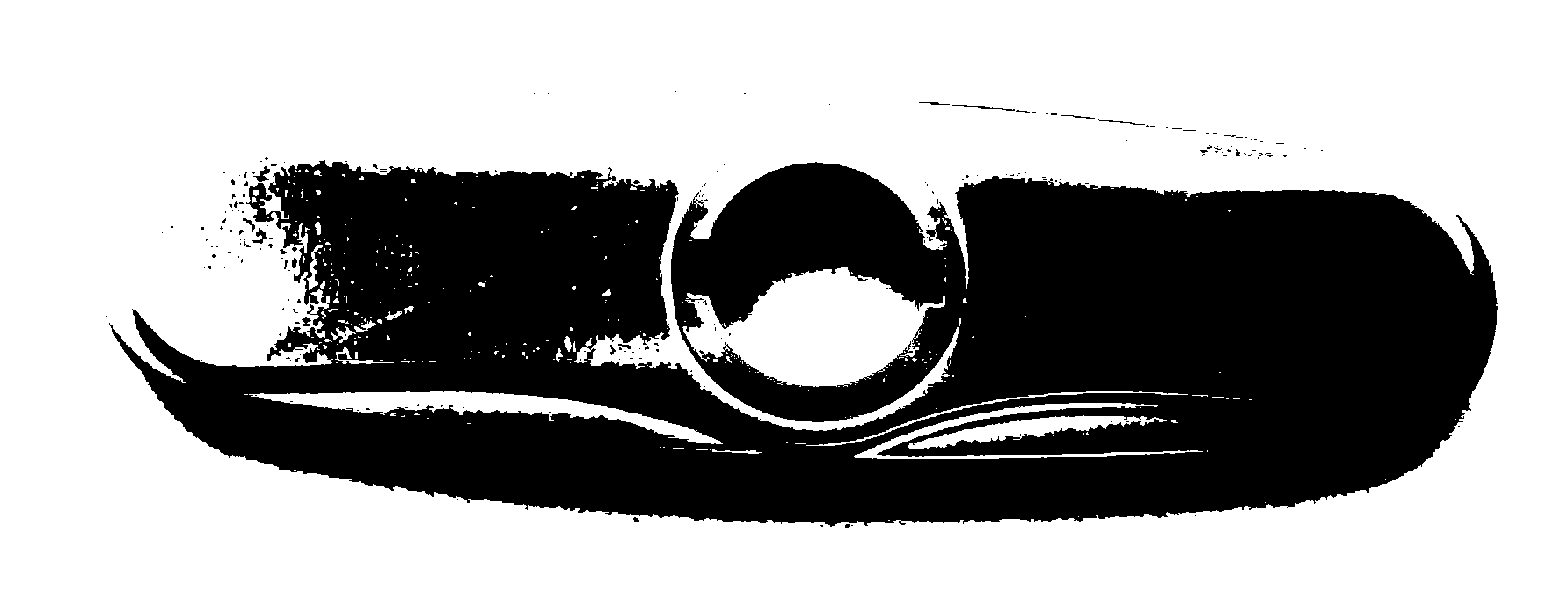

[0034] Example 1: An ABS faucet bottom cover with a brushed stainless steel appearance

[0035] 1) Manually draw the bottom cover of the ABS faucet, use nylon abrasive belt wheel for drawing, and the speed is 800r / min, to obtain the required drawing appearance;

[0036] 2) Manually wipe and degrease the plastic substrate treated in step 1), and the degreasing agent is isopropanol;

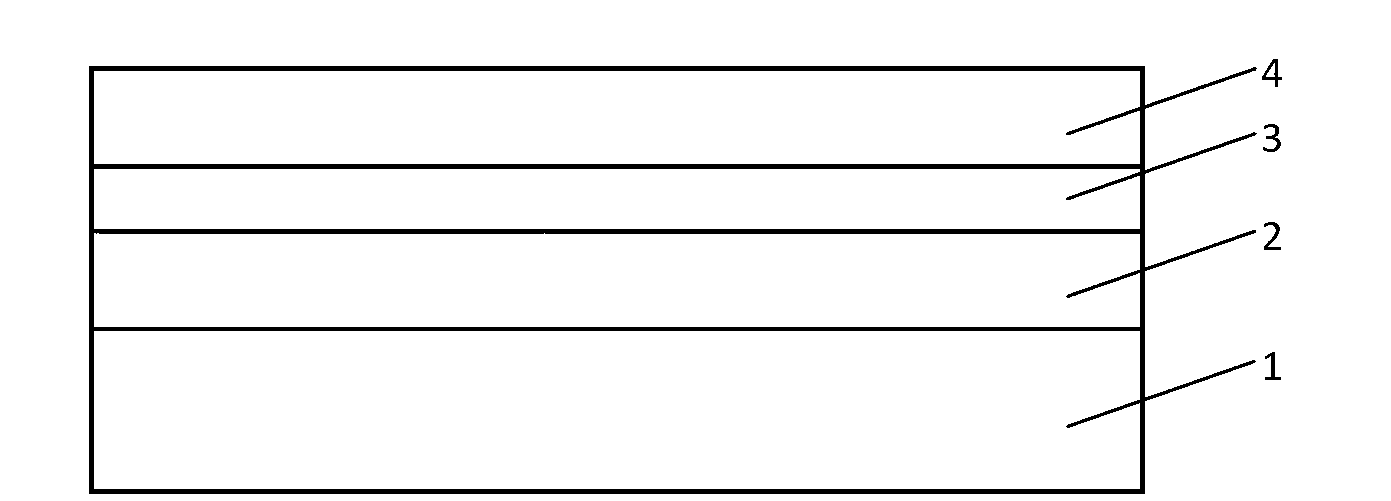

[0037] 3) Perform physical vapor deposition of metallized film on the workpiece treated in step 2), which includes plasma modification, metallized base film and conductive metal layer, and its process parameters:

[0038] a) Plasma modification: argon flow rate 50SCCM, oxygen flow rate 50SCCM, furnace vacuum 0.2Pa, activation time 5min, bias voltage 80V, ion source current 0.5A;

[0039] b) Metal plating bottom film: use high-power DC sputtering power supply, argon flow rate 200SCCM, chromium plating current 20A, bias voltage 100V, deposition time 1min;

[0040] c) Plating conductive metal layer:...

Embodiment 2

[0043] Example 2: A PA towel rack with a golden metal brushed appearance

[0044] 1) Manually draw the PA towel rack, use nylon abrasive belt wheel for drawing, and rotate at 1200r / min to obtain the required drawing appearance;

[0045] 2) Manually wipe and degrease the plastic substrate treated in step 1), and the degreasing agent is isopropanol;

[0046] 3) Perform physical vapor deposition metallization film on the workpiece treated in step 2), and then perform plasma modification, metallization base film and conductive metal layer in sequence. The process parameters are:

[0047] a) Plasma modification: argon flow rate 100SCCM, oxygen flow rate 100SCCM, furnace vacuum 0.3Pa, activation time 4min, bias voltage 100V, ion source current 0.3A;

[0048] b) Metal plating base film: use high-power DC sputtering power supply, argon flow rate 150SCCM, titanium plating current 30A, bias voltage 100V, deposition time 2min;

[0049] c) Plating conductive metal layer: use high-power ...

Embodiment 3

[0052] Example 3: A shower head made of PP material with a nickel-colored metal brushed appearance

[0053]1) Hand-drawn the PP material shower head, using nylon abrasive belt wheel for drawing, and the rotation speed is 800r / min, to obtain the required drawing appearance;

[0054] 2) Manually wipe and degrease the plastic substrate treated in step 1), and the degreasing agent is isopropanol;

[0055] 3) Perform physical vapor deposition metallization film on the workpiece treated in step 2), and then perform plasma modification, metallization base film and conductive metal layer in sequence. The process parameters are:

[0056] a) Plasma modification: argon flow rate 100SCCM, oxygen flow rate 100SCCM, furnace vacuum 0.3Pa, activation time 5min, bias voltage 150V, ion source current 0.5A;

[0057] b) Metal plating base film: use high-power DC sputtering power supply, argon flow rate 150SCCM, chromium plating current 35A, bias voltage 100V, deposition time 3min;

[0058] c) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com