Water-supply type gear grinding machine for saw blade bevel angles

A technology for gear grinding machines and saw blades, which is applied in metal sawing equipment, metal processing machinery parts, tool trimming of sawing machine devices, etc., and can solve the problems such as difficult to grasp the sawing path of saw blades, not sharp enough saw teeth, and easy blunt mouth of saw teeth, etc. , to achieve the effect of novel structure, labor-saving production, and long-lasting and sharp sawtooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

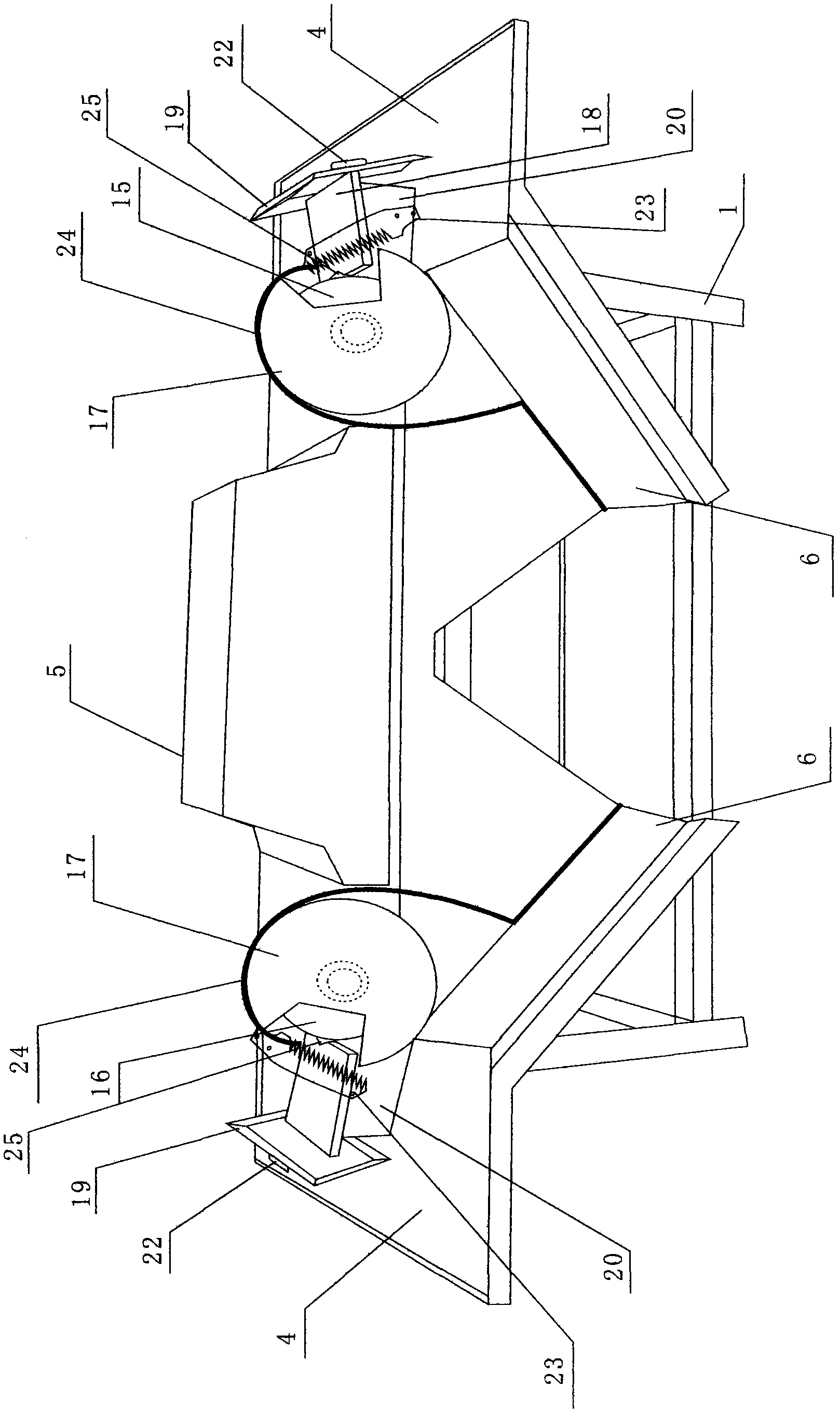

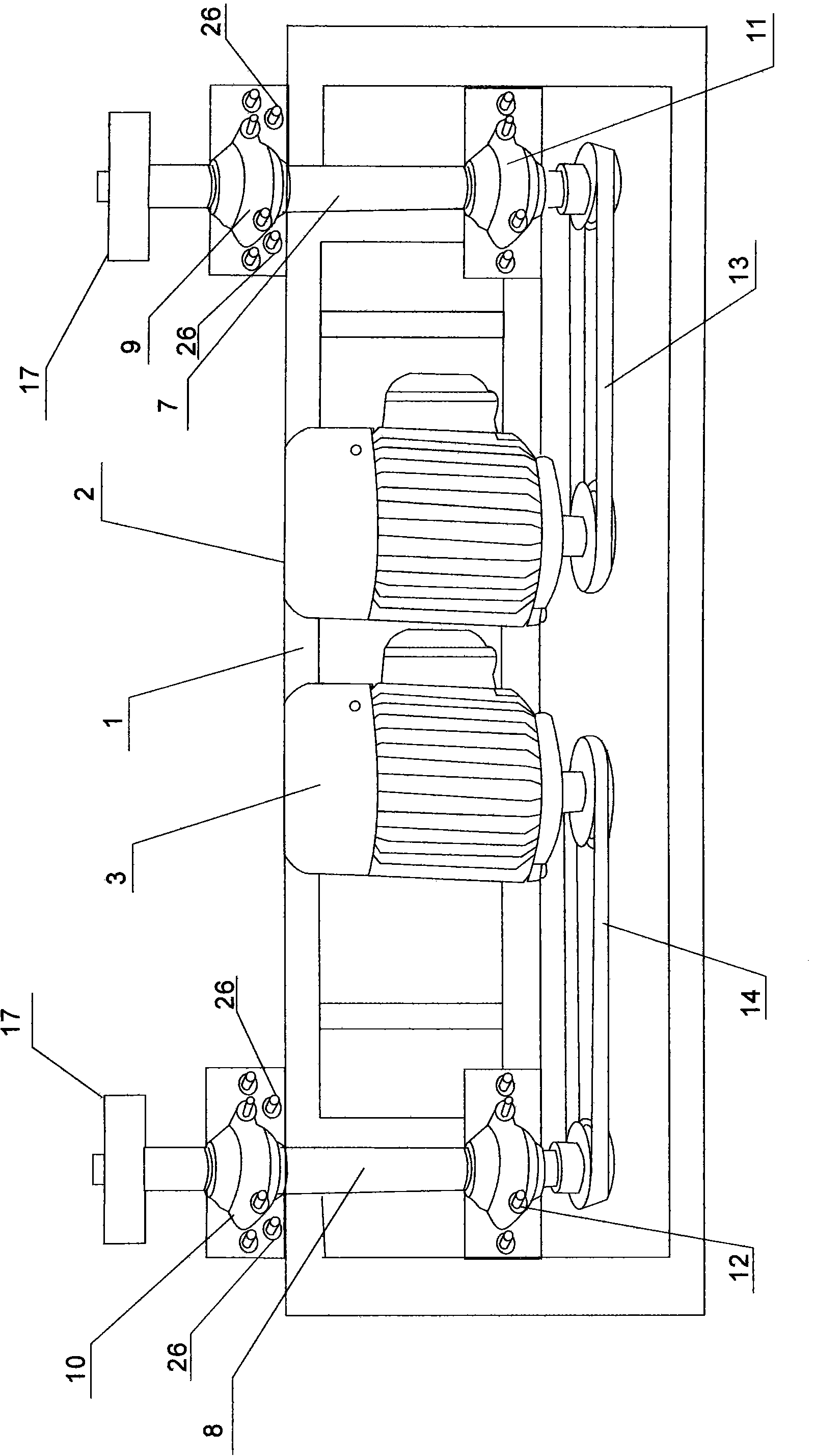

[0019] Such as figure 1 , 2 As shown in and 3, a water-feeding saw blade bevel gear grinding machine is composed of a frame, a power unit, a sliding workpiece operating table, a grinding wheel device and a water supply pipe, and is characterized in that: a power unit is arranged in the frame (1), The power unit is two motors (2) and (3) which are arranged correspondingly and rotate correspondingly to the left and right respectively; there are working panels (4) at both ends of the upper part of the frame (1), and a power unit protective cover ( 5), the other side is provided with an inverted "eight"-shaped chip guide bucket (6) under the grinding wheel device (15), (16); Both ends work panel (4) front part.

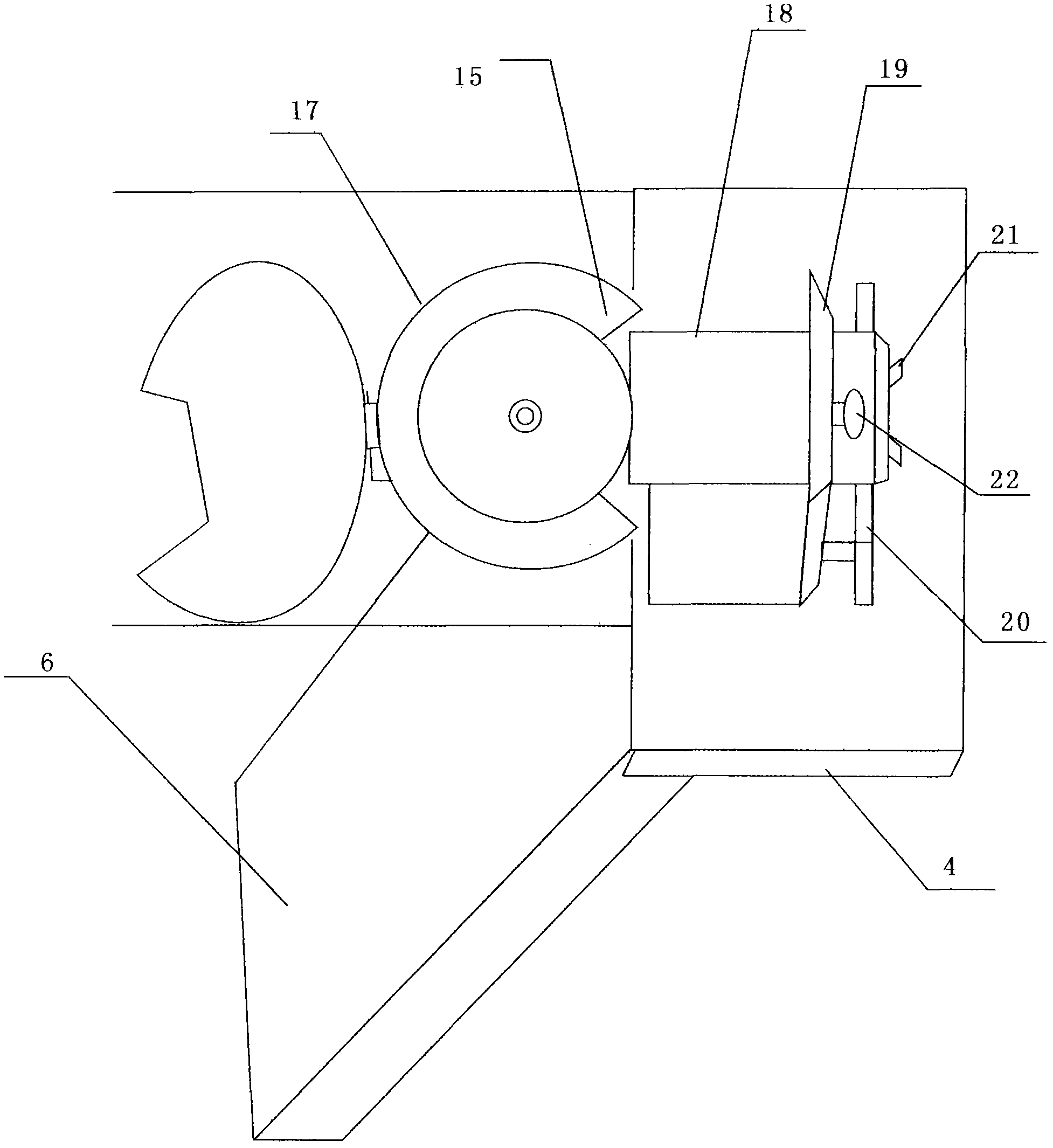

[0020] Such as figure 2 As shown, the grinding wheel device is composed of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com