Punching processing quality control method of large-scale covering component

A quality control method and stamping processing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low detection efficiency, and unreliable detection results of on-site inspection personnel, so as to improve detection accuracy and Detection efficiency, little influence of human factors, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

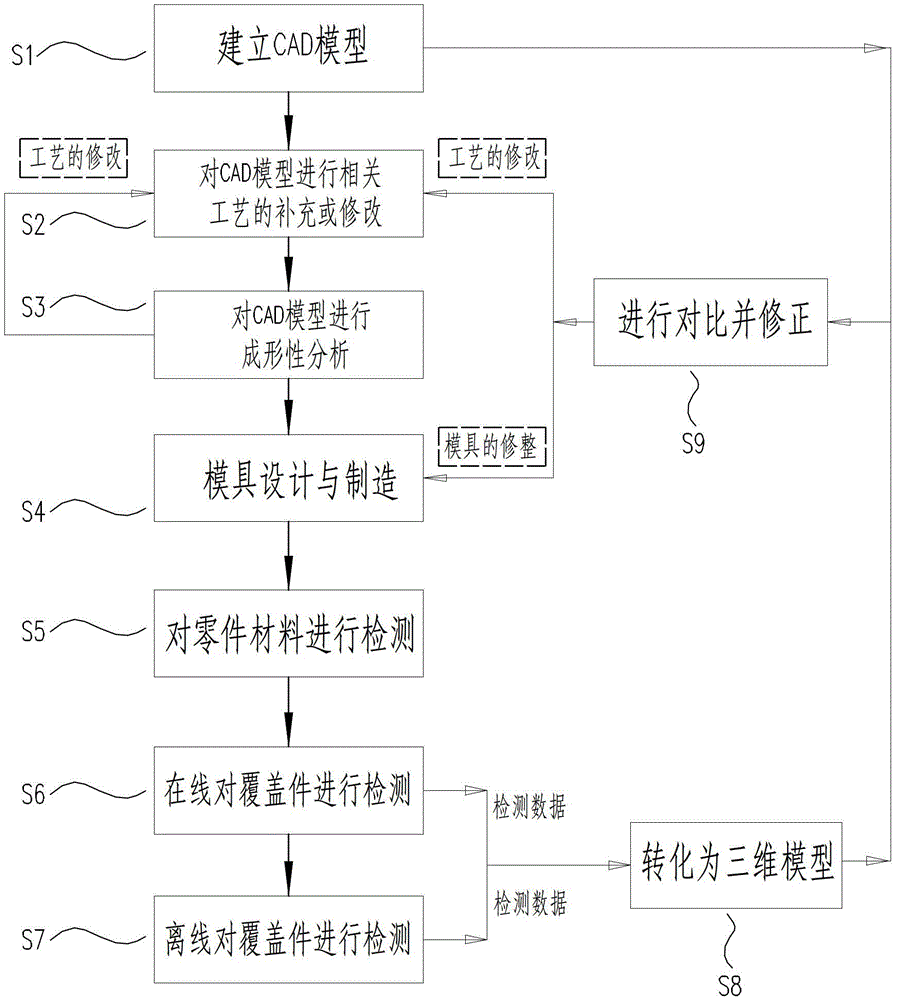

[0053] A method for controlling the stamping quality of a large cover, the method comprising the following steps:

[0054] S1. Establish CAD model:

[0055]Establish a CAD (abbreviation for Computer Aided Design, translated as computer-aided design) model of the corresponding cover according to the prototype of the cover or the drawing of the cover;

[0056] S2. Add relevant supplementary processes to the CAD model:

[0057] According to the actual situation and subsequent mold manufacturing-related restrictions, some process supplements are made to the CAD model. Reasonable process supplements make the stamping parts easy to form, especially for the formation of special shapes;

[0058] S2. Supplement or modify related processes to the CAD model:

[0059] Supplement or modify the relevant process of the CAD model according to the actual situation and subsequent mold manufacturing related restrictions;

[0060] S3. Perform formability analysis:

[0061] Analyze the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com