Cerium/aluminum-based composite oxide with high specific surface area and its preparation method

A composite oxide, high specific surface area technology, used in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of large equipment, poor high temperature aging resistance, and high production costs, and can inhibit grain growth. Large, good thermal stability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

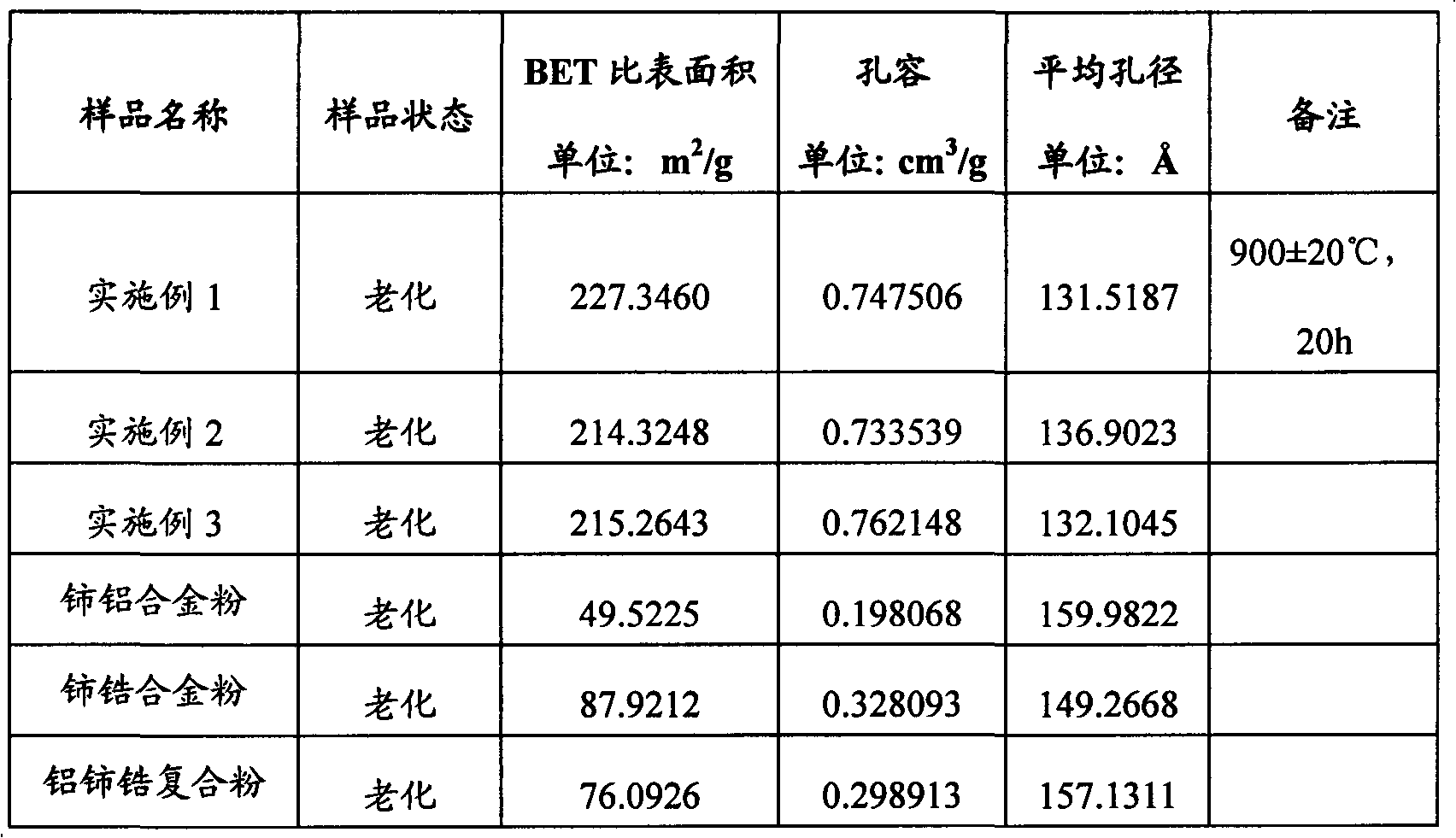

Examples

Embodiment 1

[0034] This example illustrates that the general chemical formula is Al 0.75 Ce 0.2 R 0.05 o 2 Preparation of Ce-Al-based composite oxides:

[0035] 1.5mol Al(NO 3 ) 3 9H 2 O, 0.4mol Ce(NO 3 ) 3 ·6H 2 O, 0.1mol La(NO 3 ) 3 ·6H 2Make 800ml mixed solution of O and deionized water, heat to 45±5℃, add 15g of additive (polyethylene glycol), stir for 10 minutes, then add 600ml of precipitant prepared by 5M ammonia water and 4mol hydrogen peroxide , the pH value in the reaction system will gradually increase during the dropping process, keep stirring until all the precipitant is added, control the temperature of the reaction system at 45±5°C, the pH of the reaction system=9.0±0.5, white precipitates are formed, continue to stir The reaction mixture was 30 minutes, the precipitate was filtered, washed three times with deionized water and ethanol respectively, and then the precipitate was dried in a blast oven at 110±10°C for 10 hours, and then roasted in a vacuum oven at 5...

Embodiment 3

[0039] This example illustrates that the general chemical formula is Al 0.45 Ce 0.5 R 0.05 o 2 Preparation of Ce-Al-based composite oxides:

[0040] 1.35mol Al(NO 3 ) 3 9H 2 O, 1.5mol Ce(NO 3 ) 3 ·6H 2 O, 0.15mol La(NO 3 ) 3 ·6H 2 Make 800ml mixed solution of O and deionized water, heat to 45±5℃, add 30g of additive (polyethylene glycol), stir for 10 minutes, then add 800ml of precipitant prepared by 5M ammonia water and 5mol hydrogen peroxide , the pH value in the reaction system will gradually increase during the dropping process, keep stirring until all the precipitant is added, control the temperature of the reaction system at 50±5°C, the pH of the reaction system=10.0±0.5, white precipitate is formed, continue to stir Reaction mixture for 30 minutes, filter the precipitate, wash with deionized water and ethanol three times respectively, then dry the precipitate in a blast oven at 110±10°C for 10 hours, then bake in a vacuum oven at 600±20°C for 3 hours , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com