Self-repairing chromium-free passivation treatment fluid used for galvanized steel coil

A chromium-free passivation and self-healing technology, applied in the direction of metal material coating process, etc., can solve the problems that the film layer does not have self-healing ability and low corrosion resistance, so as to solve the problem of chromium pollution, low processing temperature, prevent Intrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

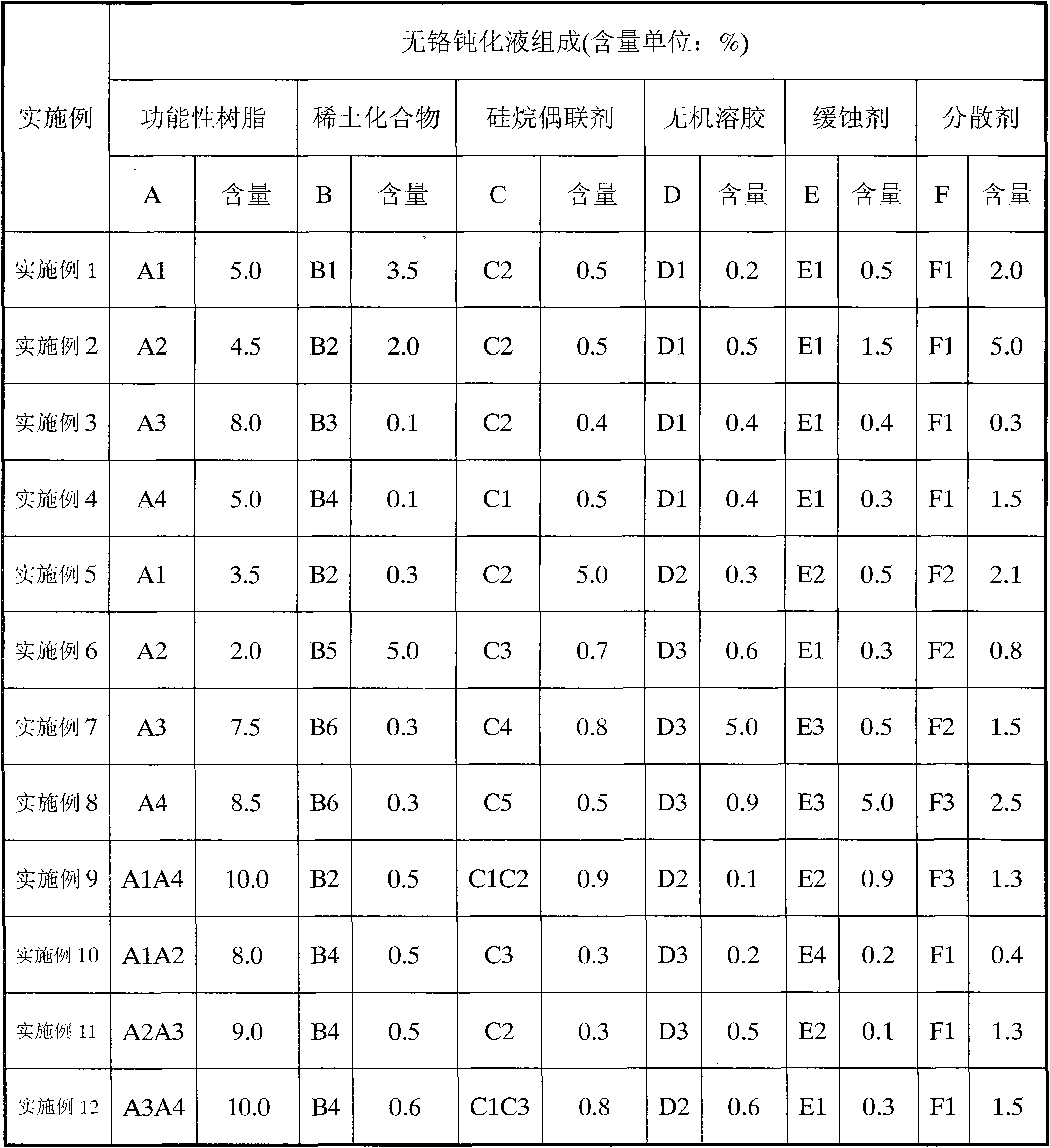

Examples

Embodiment 1

[0034] A self-repairing chrome-free passivation treatment solution for galvanized coil steel, comprising the following components (by weight):

[0035] Polyacrylic acid 5.0%, LaCl 3 3.5%, γ-glycidyl etheroxypropyl trimethoxysilane 0.5%, ZnO sol 0.2%, NaMoO 4 0.5%, PEG-1000 2.0%, the balance is water.

[0036] The optimum pretreatment temperature of the treatment solution is 35°C at room temperature, and the optimum treatment temperature after passivation is 50°C.

Embodiment 2

[0038] A self-repairing chromium-free passivation treatment solution for galvanized coil steel, comprising the following components (by mass percentage):

[0039] Acrylic modified polyurethane 4.5%, CeCl 3 2.0%, γ-glycidyl etheroxypropyl trimethoxysilane 0.5%, ZnO sol 0.5%, NaMoO 4 1.5%, PEG-1000 5.0%, and the balance is water.

[0040] The optimum pretreatment temperature of the treatment liquid is 25°C at room temperature, and the optimum treatment temperature after passivation is 100°C.

Embodiment 3

[0042] A self-repairing chromium-free passivation treatment solution for galvanized coil steel, comprising the following components (by mass percentage):

[0043] Fluorine modified polyurethane 8.0%, La(NO 3 ) 3 0.1%, γ-glycidyl etheroxypropyl trimethoxysilane 0.4%, ZnO sol 0.4%, NaMoO 4 0.4%, PEG-1000 0.3%, and the balance is water.

[0044] The optimum pretreatment temperature of the treatment solution is 35°C at room temperature, and the optimum treatment temperature after passivation is 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com