Multifunctional biomass heat conversion equipment and process

A biomass, multi-functional technology, applied in inorganic chemistry, petroleum industry, carbon compounds, etc., can solve the problems of burn-through, tar black water pollution, complicated operation, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

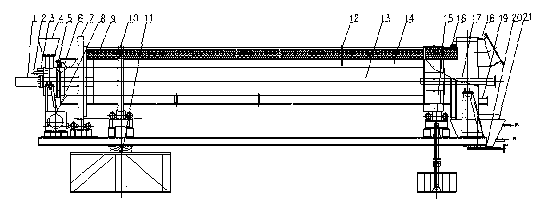

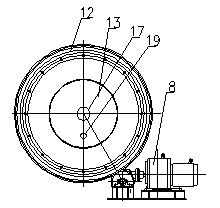

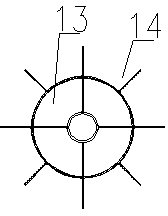

[0022] When used as a carbonization equipment, firstly adjust the screw and (8) transmission and gearbox through the (15) angle in advance according to the nature of the raw material, initially adjust the inclination angle and speed of the equipment, and then use liquefied gas to burn in the (13) combustion channel, Heat the temperature of the entire cylinder to 400°C, then use the automatic feeding mechanism to feed the raw materials into (4) the feed port, open the chimney valve, and adjust the flow of flue gas through the chimney valve until the raw material produces combustible gas during pyrolysis , withdraw the liquefied gas ignition equipment, adjust the oxygen supply of (19) the combustion port to control the carbonization temperature between 500-650 ° C, and continue to fine-tune according to the fixed carbon content and yield of the product when the equipment has product output (19) Oxygen supply to the combustion port, (15) angle adjustment screw and (8) transmission...

Embodiment 2

[0024] When used as an activation device, firstly, according to the density and size of the raw material, adjust the screw and (8) transmission and gearbox in advance through the (15) angle, initially adjust the inclination angle and speed of the equipment, and then use liquefied gas in the (13) combustion channel Combustion, heat the temperature of the entire cylinder to 600°C, then use the automatic feeding mechanism to feed the raw materials into (4) the feed port, open the chimney valve, and adjust the flue gas flow through the chimney valve, when the temperature of the cylinder reaches 800°C Withdraw the liquefied gas ignition equipment, slowly open the (2) activator inlet, and introduce a small amount of activator. After the combustible gas is generated, adjust the oxygen supply of (19) the combustion port to control the activation temperature between 850-950°C , when the equipment has product output, according to the adsorption value and decolorization value of the produ...

Embodiment 3

[0026]When used as gasification equipment, firstly adjust the screw and (8) transmission and gearbox through the (15) angle in advance according to the characteristics of the raw material, initially adjust the inclination angle and speed of the equipment, and then use liquefied gas to burn in the (13) combustion channel , heat the temperature of the entire cylinder to 500°C, then use the automatic feeding mechanism to feed the raw materials into (4) the feed port, slowly open the (2) gasification agent inlet, pass in a small amount of gasification agent, and open the chimney Valve, adjust the flue gas flow through the chimney valve, withdraw the liquefied gas ignition equipment when the temperature of the cylinder body reaches 650 °C, after the combustible gas is generated, adjust the oxygen supply of (19) the combustion port to control the activation temperature between 900-950 °C During the period, when the equipment has product output, according to the tar content of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com