High-temperature alloy surface nanometer composite coating and preparation method thereof

A nano-composite coating and high-temperature alloy technology, which is applied in metal material coating technology, coating, fusion spraying, etc., can solve the problems of poor bonding, low coating toughness, pesting phenomenon, etc., and achieve simple process and environmental protection The effect of less pollution and excellent high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

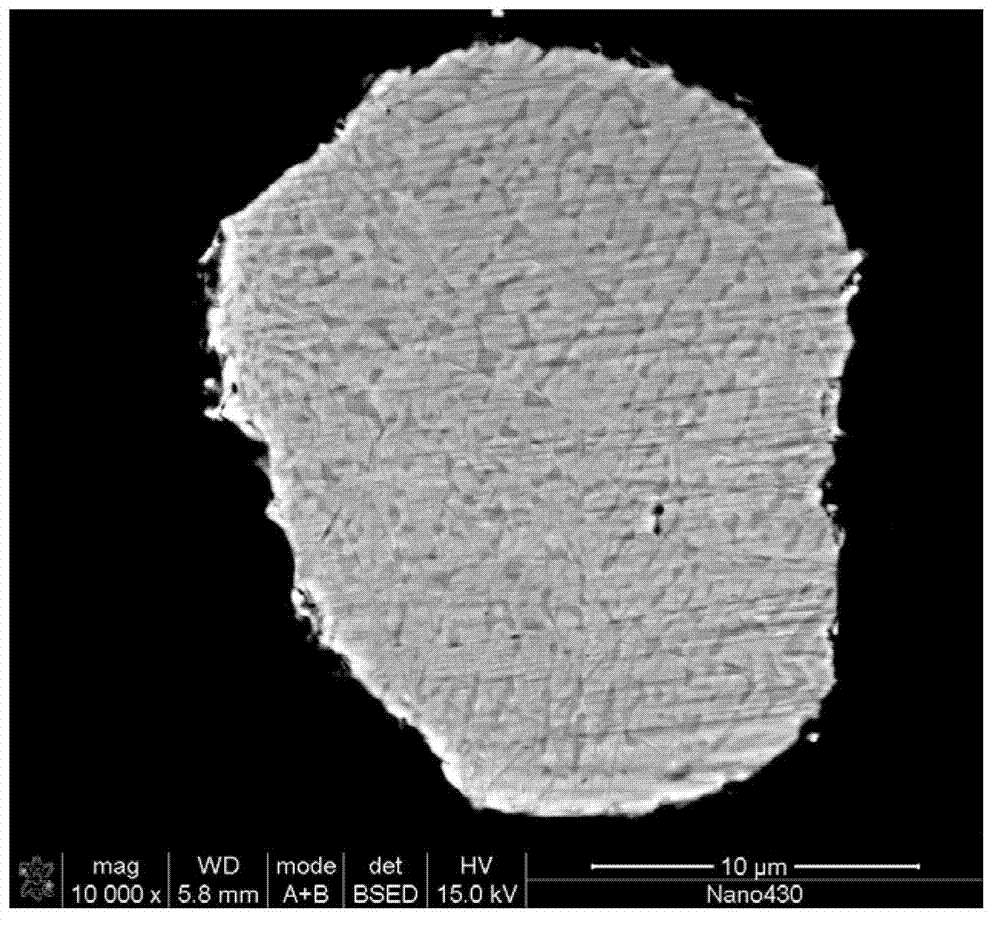

Image

Examples

Embodiment 1

[0043] (1) Preparation and cleaning of the base material: GH4169 nickel-based alloy was selected as the base material, and after the base material was cut into square sheets, the base material was ultrasonically cleaned with acetone and deionized water for 15 minutes, and then the base material was wiped with filter paper. The surface of the material is air-dried for later use;

[0044] (2) Sand blasting treatment: use corundum sand with a particle size of 500-700 μm to perform sand blasting roughening treatment on the surface of the substrate treated in step (1), the sand blasting pressure is 0.20MPa, the sand blasting angle is about 70°, The time is 20s;

[0045] (3) Preheating treatment: Preheat the substrate treated in step (2) to 150°C by using plasma jet flame;

[0046] (4) Plasma spraying: Nano-MoSi successfully prepared in the previous period 2 - CoNiCrAlY composite structure particles are fed as spray powder, and the substrate treated in step (3) is plasma sprayed. ...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that the spraying distance in step (4) is 100 mm, and the powder feeding amount is 5 g / min.

Embodiment 3

[0055] The differences between this embodiment and embodiment 1 are: the spraying distance in step (4) is 100 mm, and the powder feeding rate is 10 g / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com