Preparation method of high-corrosion-resistance polyarylene sulfide sulfone separation membrane

A polyarylene sulfide sulfone, high corrosion resistance technology, applied in the field of membrane material preparation, can solve the problems of low conversion rate, high temperature oxidation is difficult to control, membrane pores are easy to lose water and deform, and achieve strong stability and good size The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

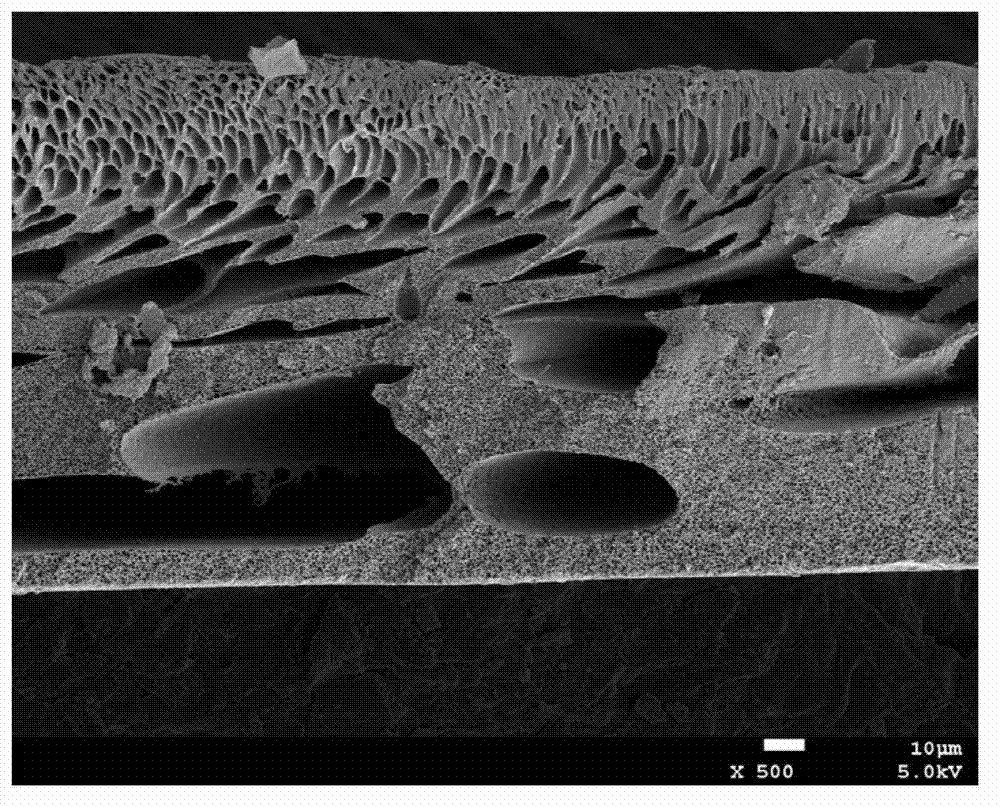

[0036] Example 1: Preparation of high corrosion resistance polyarylene sulfide sulfone flat membrane

[0037] Add 18g of polyarylene sulfide sulfone resin, 77g of N-methylpyrrolidone, and 5g of polyethylene glycol into a dissolution kettle equipped with a stirrer and a thermometer, stir and dissolve at a temperature of 60°C, and defoam at a vacuum degree of 0.1MPa for 5h to prepare into a uniform film-making solution. Scrape the film-making solution evenly on the quartz glass plate (temperature 40°C) with a flat-plate scraping machine, then immerse the nascent film in deionized water (25°C) to replace the additives and solvents, and the gel is solidified into polyarylene sulfide Sulfone separation membrane.

[0038] The prepared polyarylene sulfide sulfone separation membrane was immersed in 50 ml of glacial acetic acid, and 15 ml of hydrogen peroxide was added under magnetic stirring. After constant temperature at 80°C for 7 hours, wash with deionized water, and then go thr...

Embodiment 2

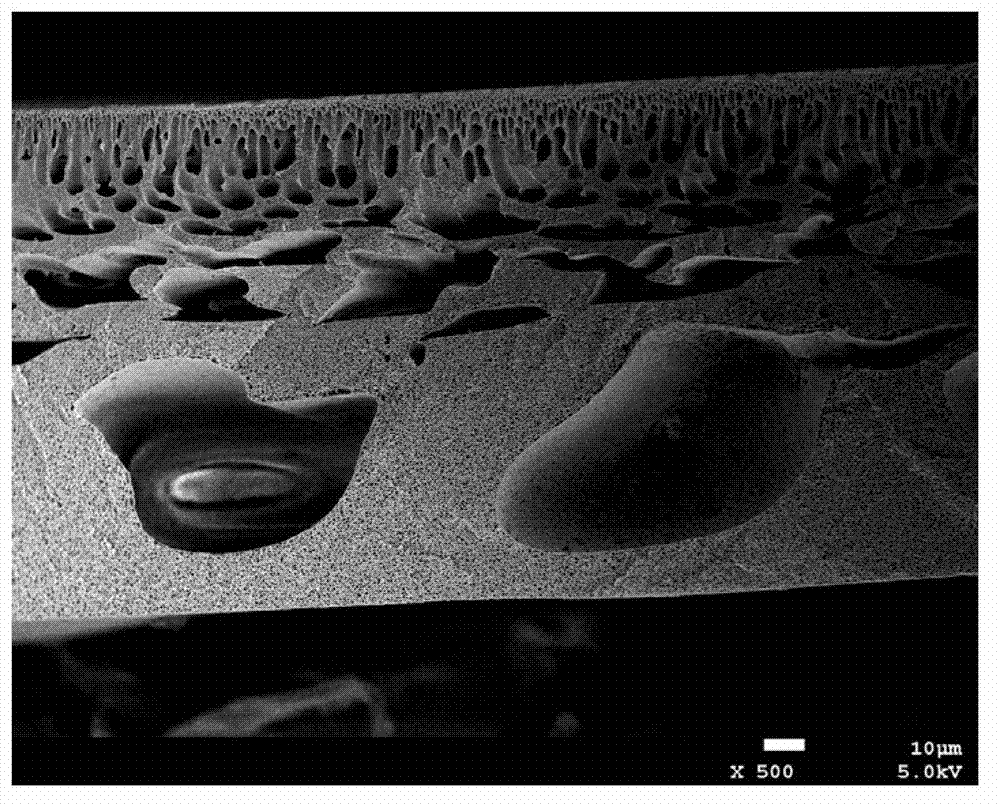

[0039] Example 2: Preparation of High Corrosion Resistance Polyarylene Sulfide Hollow Fiber Membrane

[0040] Put 200g of polyarylene sulfide sulfone resin, 750g of N-methylpyrrolidone, 30g of polyvinyl alcohol, and 20g of zinc chloride into a dissolution kettle to dissolve at 150°C, filter to remove solid impurities, and vacuum defoam at -0.4MPa to prepare a spinning solution.

[0041] The hollow fiber membrane is prepared by dry-wet spinning, the inner diameter of the spinneret is 0.9mm, the outer diameter is 1.4mm, the spinning rate is 10ml / min, the draw ratio is 3 times, the external coagulation bath is water, and the core liquid is 50% ethanol solution.

[0042] Then put a bundle of 15cm long hollow fiber membranes into a measuring cylinder filled with 100ml ethanol, 10ml98% concentrated sulfuric acid, and 10ml hydrogen peroxide. The finished product of polyarylene sulfide sulfone hollow fiber membrane. Pore preserving agent is 30wt% glycerol aqueous solution.

Embodiment 3

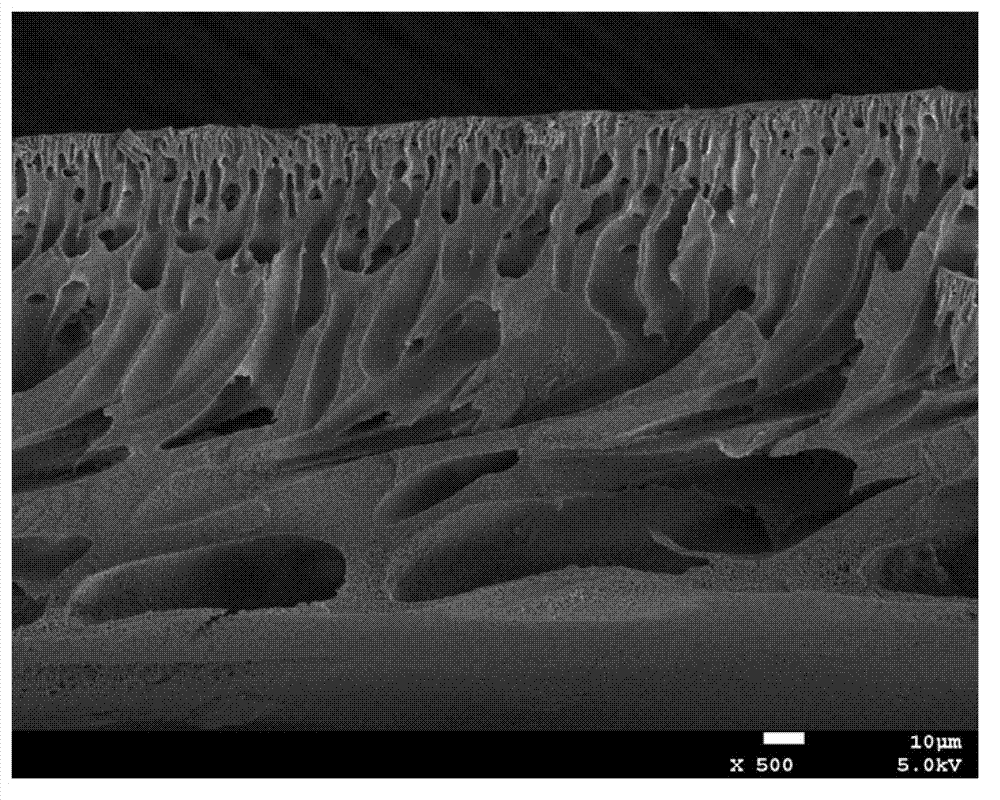

[0043] Example 3: Preparation of highly corrosion-resistant polyarylene sulfide sulfone cation separation membrane

[0044]Solution 1 was prepared by dissolving 16 g of chloromethylated polyarylene sulfide sulfone in 84 g of N-methylpyrrolidone. Solution 2 was prepared by dissolving 18 g of sulfonated polyarylene sulfide sulfone in 82 g of N-methylpyrrolidone. Cast solution 1 on a glass plate, heat and dry in a constant temperature drying oven at 110°C for 30 minutes to form a polymer base film, then coat solution 2 on the copolymer layer, and then spread a layer on the nascent film. A 0.14mm thick polypropylene non-woven fabric was laid, heated and dried in a constant temperature drying oven at 110°C for 30 minutes, and the product was peeled off from the glass plate to prepare a double-layer composite film.

[0045] Soak the prepared dense polyarylene sulfide sulfone membrane in a mixed solution of 200ml acetic acid and 50ml peracetic acid at a constant temperature of 30°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com