Surface-treated fluorescent bodies and process for production of surface-treated fluorescent bodies

A technology for surface treatment and manufacturing method, applied in the field of surface-treated phosphor manufacturing, can solve the problems of reaction efficiency and cost, uneven coverage of pinholes, reduced fluorescence characteristics, etc., and achieves improved moisture resistance, high stability, and moisture resistance. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Containing 0.1mol / L ammonium fluoride titanate ((NH 4 ) 2 TiF 6 ) and 0.1mol / L boric acid mixed aqueous solution 250ml to add the central particle size (D 50 ) about 17μm orange silicate phosphor (Sr 3 SiO 5 :Eu 2+ )7.5g. The above-mentioned phosphor-added liquid mixture was stirred and dispersed, and reacted at 35° C. for 2 hours. After the reaction, the phosphor recovered through the filtration and washing steps was vacuum-dried at 120° C. for 1 hour.

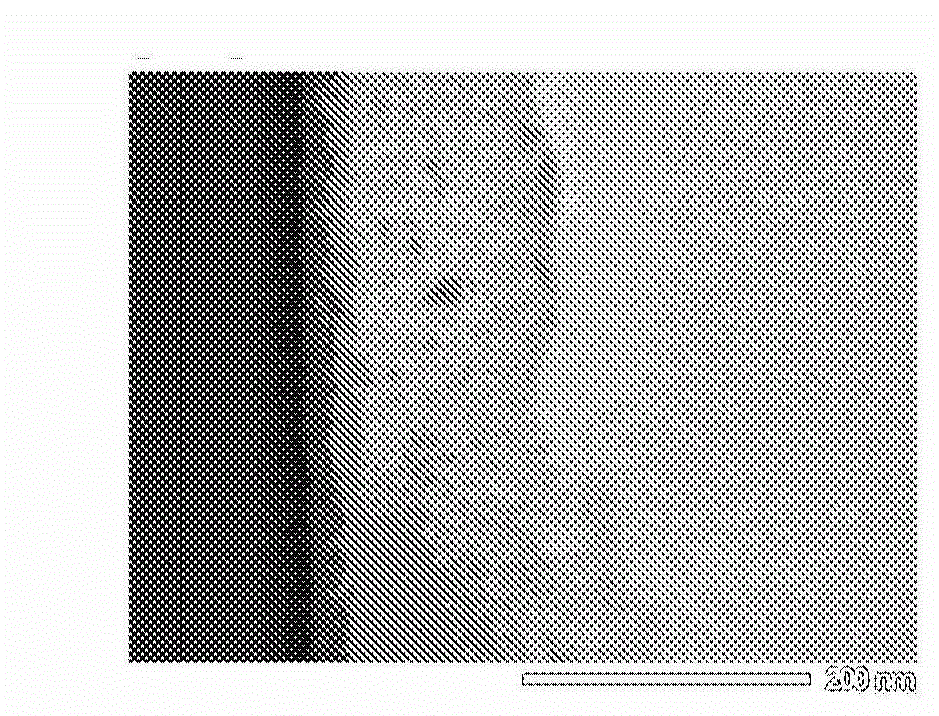

[0157] The obtained surface-treated phosphor was subjected to "measurement of the thickness of the coating layer and elemental composition analysis in the cross-sectional direction" by the following method. As a result, it was found that a surface-treated layer with a thickness of about 180 nm was formed on the surface of the phosphor.

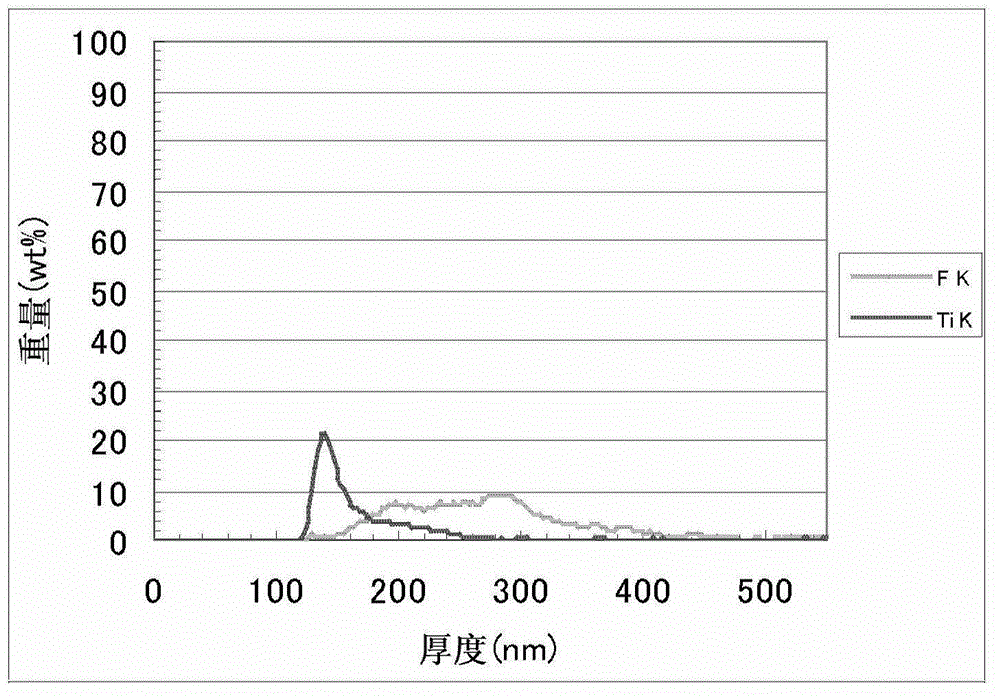

[0158] In addition, in the elemental composition curve obtained by the elemental composition analysis in the cross-sectional direction, it was confirmed that a curve showing the...

Embodiment 2

[0164] Containing 0.1mol / L ammonium fluoride titanate ((NH 4 ) 2 TiF 6 ) and 0.1mol / L boric acid mixed aqueous solution 250ml to add the central particle size (D 50 ) about 17μm orange silicate phosphor (main component: Sr 3 SiO 5 :Eu 2+ )7.5g. The above-mentioned phosphor-added liquid mixture was stirred and dispersed, and reacted at 35° C. for 4 hours. After the reaction, the phosphor recovered through the filtration and washing steps was vacuum-dried at 120° C. for 1 hour.

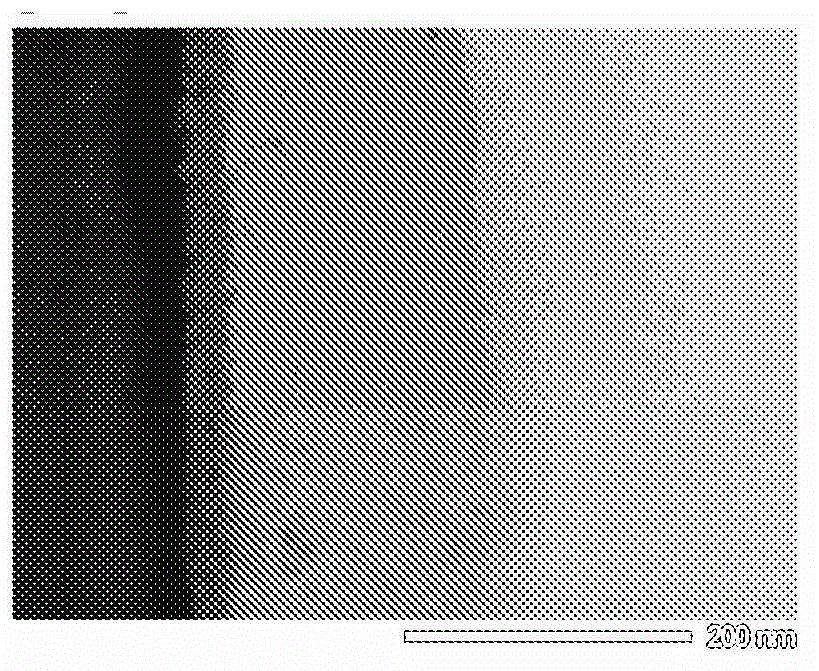

[0165] The obtained surface-treated phosphor was subjected to "measurement of the thickness of the coating layer and elemental composition analysis in the cross-sectional direction" in the same manner as in Example 1. As a result, it was found that a surface-treated layer with a thickness of about 210 nm was formed on the surface of the phosphor.

[0166] In addition, in the elemental composition curve obtained by the elemental composition analysis in the cross-sectional direction, it was confirm...

Embodiment 3

[0170] Containing 0.75mol / L ammonium fluoride titanate ((NH 4 ) 2 TiF 6 ) to 250ml of an aqueous solution with a central particle size (D 50 ) is about 17μm orange silicate phosphor (main component: Sr 3 SiO 5 :Eu 2+ )7.5g. While stirring and dispersing the phosphor-added liquid mixture, it was allowed to react at 35° C. for 30 minutes. After the reaction, the phosphor recovered through the filtration and washing steps was vacuum-dried at 120° C. for 1 hour.

[0171] The obtained surface-treated phosphor was subjected to "measurement of coating layer thickness and elemental composition analysis in cross-sectional direction" in the same manner as in Example 1. As a result, it was found that a coating layer with a thickness of about 250 nm was formed on the surface of the phosphor.

[0172] In addition, in the element composition curve obtained by the element composition analysis in the cross-sectional direction, it was confirmed that a curve showing the content of titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| luminous intensity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com