Preparation method and application of solid acid catalyst

A solid acid catalyst and solid technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable large-scale preparation, environmental protection, and inability to meet industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

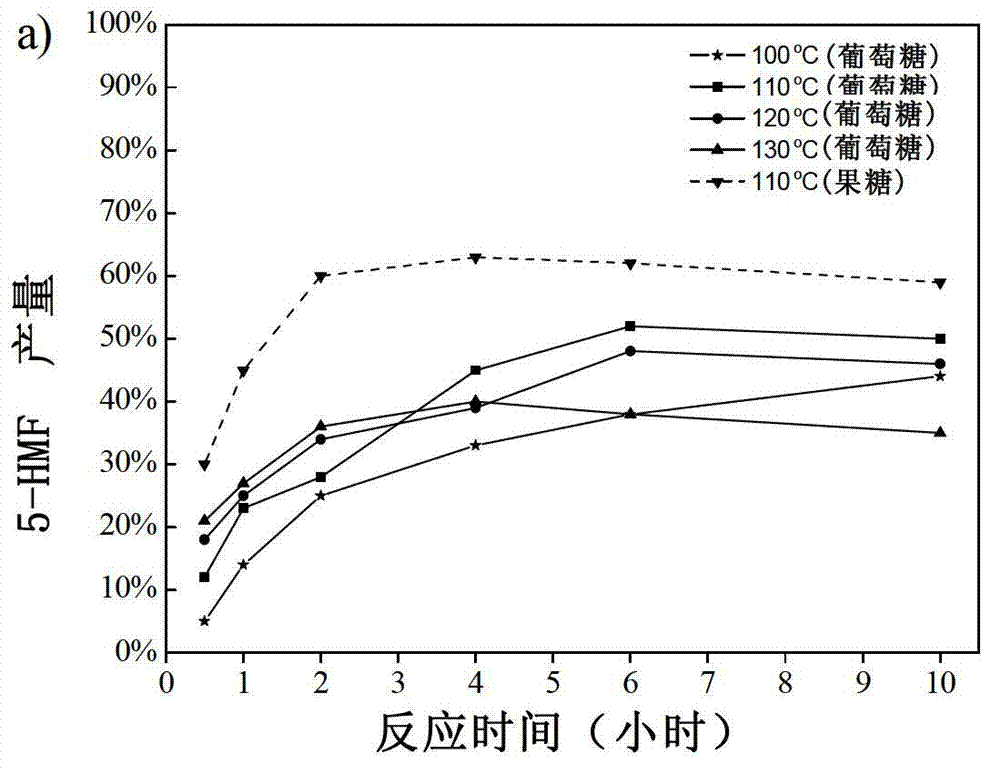

[0049] The present invention also provides a method for preparing 5-hydroxymethylfurfural, the method comprising the steps of: mixing the ionic liquid, carbohydrates and the solid acid catalyst obtained by the preparation method provided by the present invention at 100-130°C ( Preferably, 105-115°C) is reacted for 1-10 hours to obtain 5-hydroxymethylfurfural; preferably, the carbohydrate is selected from glucose or fructose; the mass percentage of the carbohydrate and the ionic liquid solvent is 8-12% ; The mass percentage of the solid acid catalyst and the ionic liquid solvent is 3-7%.

[0050] The above-mentioned features mentioned in the present invention, or the features mentioned in the embodiments can be combined arbitrarily. All the features disclosed in the specification of this case can be used in combination with any combination, and each feature disclosed in the specification can be replaced by any alternative feature that can provide the same, equivalent or similar...

Embodiment 1

[0063] Preparation of Ionic Liquids and Solid Acid Catalysts

[0064] Ionic liquid 1-methyl-3-ethylimidazole bromide ([C 2 MIM]Br) was prepared by the following method: put 0.5mol of N-methylimidazole, 0.75mol of ethyl bromide and 80ml of ethyl acetate into a 250ml round bottom flask, and reflux at 80°C for 24h in an oil bath. After the reaction, the upper ethyl acetate layer was removed, and the lower oily liquid was washed repeatedly with ethyl acetate (80ml×4). After removing the upper layer of ethyl acetate, the oily liquid in the lower layer was placed in a vacuum oven, and dried in vacuum at 80°C for 12 hours to obtain [C 2 MIM] Br.

[0065] Ionic liquid 1-methyl-3-butylimidazole bromide ([C 4 MIM]Br) was prepared by the following method: put 0.5mol of N-methylimidazole, 0.75mol of 1-bromobutane and 80ml of ethyl acetate into a 250ml round bottom flask, and reflux at 80°C for 24h in an oil bath. After the reaction, the upper ethyl acetate layer was removed, and the l...

Embodiment 2

[0076] Preparation of 5-Hydroxymethylfurfural

[0077] Add 1.0g ionic liquid [C 2 MIM] Br, 100 mg glucose and 50 mg solid acid catalyst Sn-MCM-41 (50). Then the reaction tube was placed in an oil bath containing electromagnetic stirring, and reacted at 110°C for 6 hours, the conversion rate of glucose was 99%, and the yield of 5-HMF was 51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com