Inclined axis hydraulic rotary machine

A rotary machine and hydraulic technology, applied in the direction of variable capacity engines, liquid fuel engines, liquid variable capacity machines, etc., can solve problems such as hot sticking and seizure, reduce wear, suppress heat generation, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

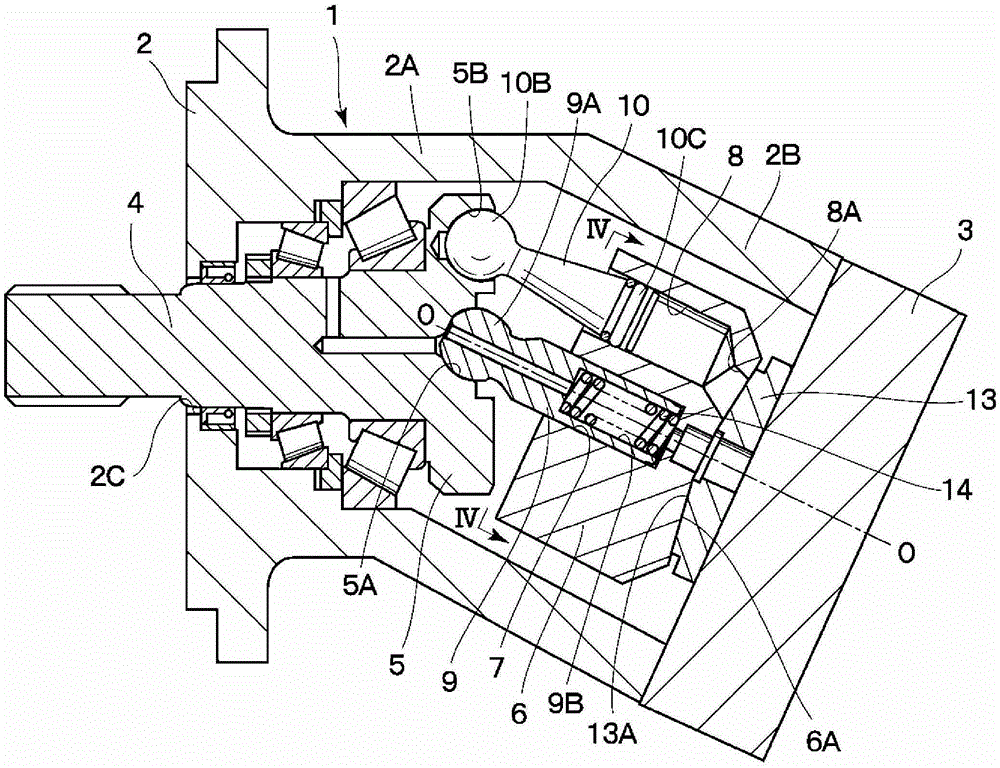

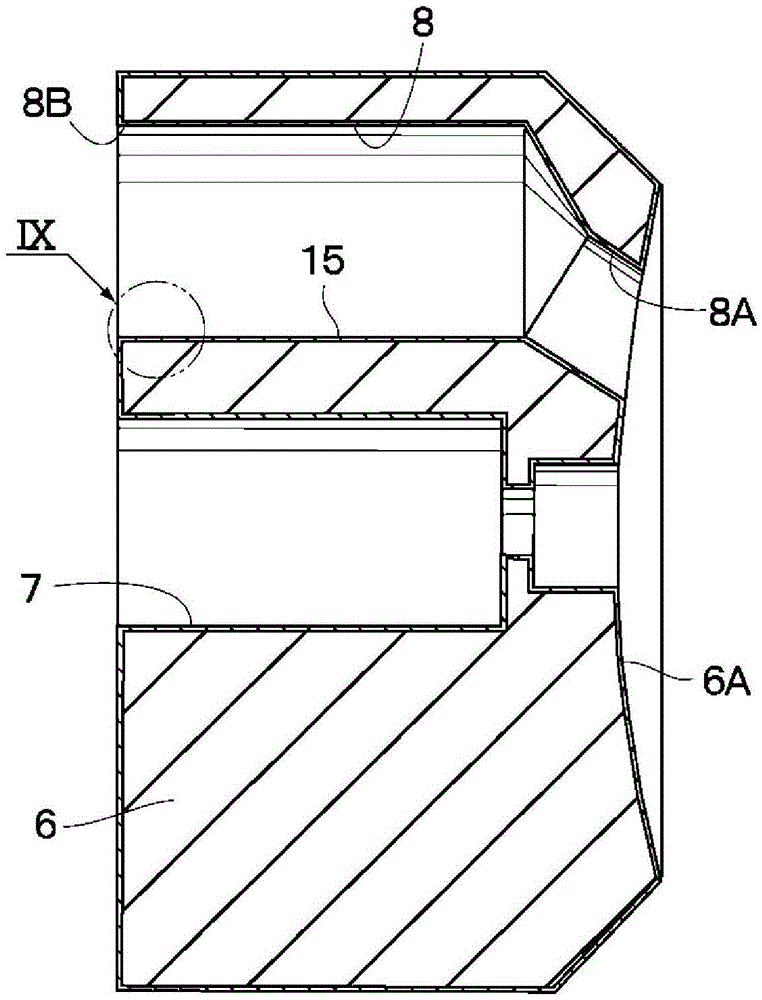

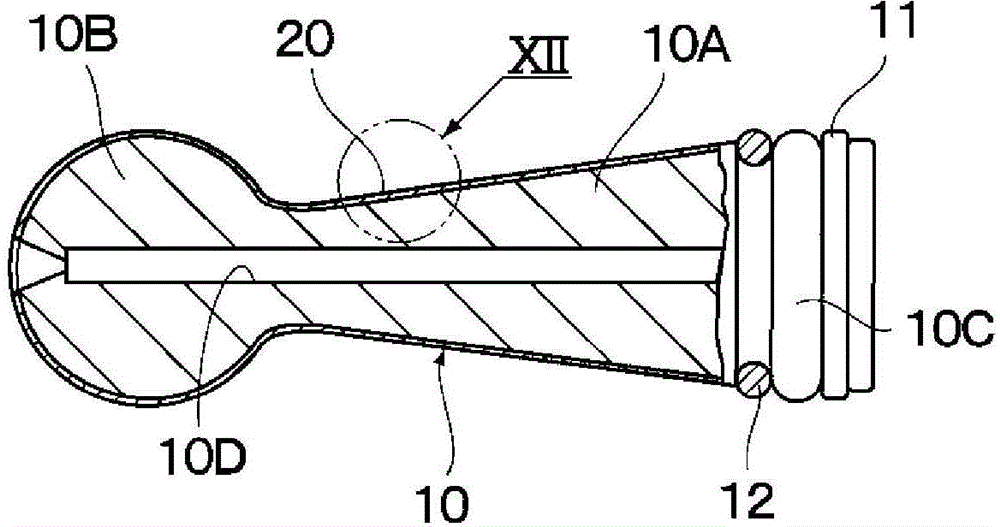

[0043] Hereinafter, a case in which the inclined-axis hydraulic rotary machine according to the embodiment of the present invention is applied to a fixed-capacity inclined-axis hydraulic motor will be described in detail with reference to the drawings.

[0044] Figure 1 to Figure 16 The first embodiment of the inclined axis type hydraulic rotary machine of the present invention is shown.

[0045] In the figure, 1 is a casing of a hydraulic motor which is a representative example of an inclined axis type hydraulic rotary machine. The housing 1 is composed of a cylindrical housing main body 2 bent in the middle in the longitudinal direction, and a head housing 3 described later.

[0046] The housing body 2 is composed of a one-side cylindrical portion 2A located on one side in the axial direction and another side cylindrical portion 2B on the other axial side, and the intermediate portion between the one-side cylindrical portion 2A and the other-side cylindrical portion 2B is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com