One step filature method for fresh cocoons of silkworms

A technology of fresh cocoons and silkworms, applied in silk reeling, textiles, papermaking, mechanical processing, etc., can solve the problems of environmental pollution, coal burning, etc., achieve the effects of cost reduction, easy operation, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

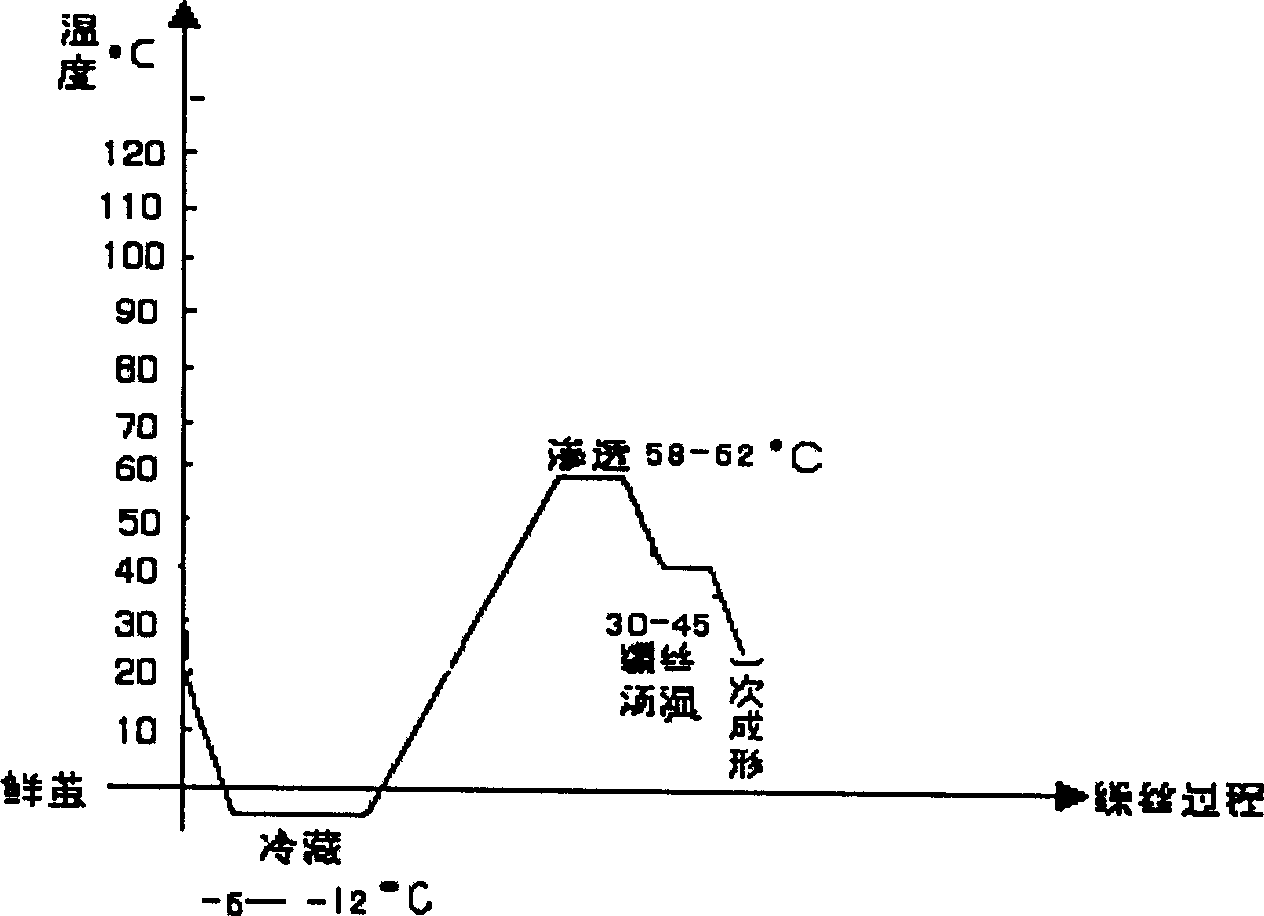

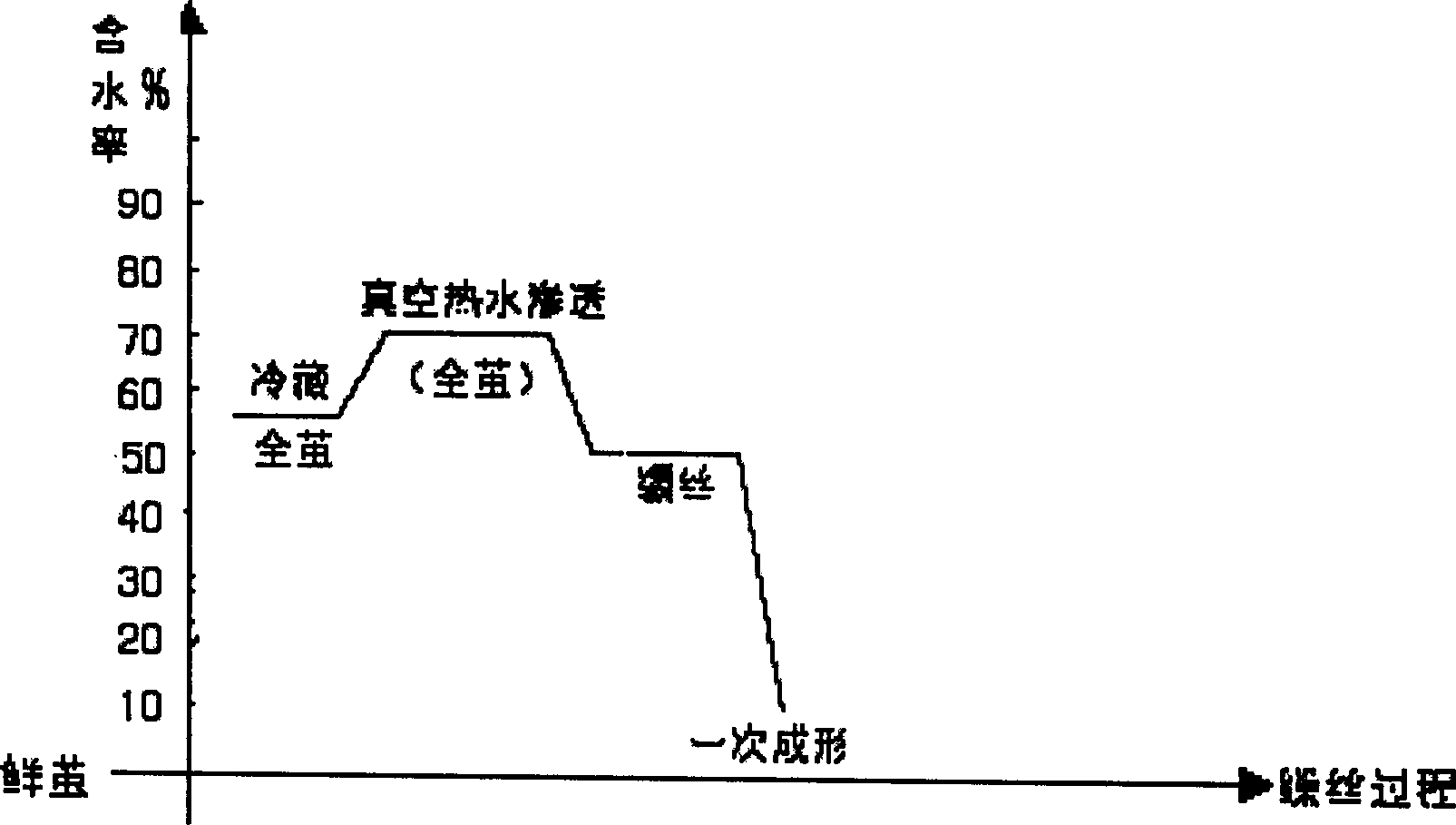

[0030] The one-step silk reeling process is as follows:

[0031] Fresh cocoon acquisition—→frozen freshness preservation—→cocoon quality investigation process design—→fresh cocoon mixing, peeling, sieving, sorting—→vacuum hot water penetration—→silk reeling—→rolling and forming—→weighing silk—→wrapping silk— →The finished silk is put into storage. The specific steps are as follows:

[0032] ① Purchase fresh cocoons. The fresh cocoons purchased according to the national or local standard quality must not be steamed, and the fresh cocoons should be loosely packed into plastic baskets, and it is advisable to fill them full. The cocoon baskets are piled up in the shape of "pin", and they are transported to the cold storage on the day of purchase. .

[0033] ②Frozen and fresh preservation. The temperature of frozen fresh cocoons is -6~-12°C, and the relative air temperature in the warehouse should not be lower than 80%. The storage time of cold treatment can be as long as 9 mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com