Biaxially oriented polyarylene sulfide resin film and process for production of same

A polyarylene sulfide and biaxial stretching technology, which is applied in the biaxially stretched polyarylene sulfide resin film and its manufacturing field, can solve the problems of poor peelability and detachment of the inorganic filler film, and achieve flatness and smoothness. Harmonious slip properties, small coefficients of static and kinetic friction, and excellent releasability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

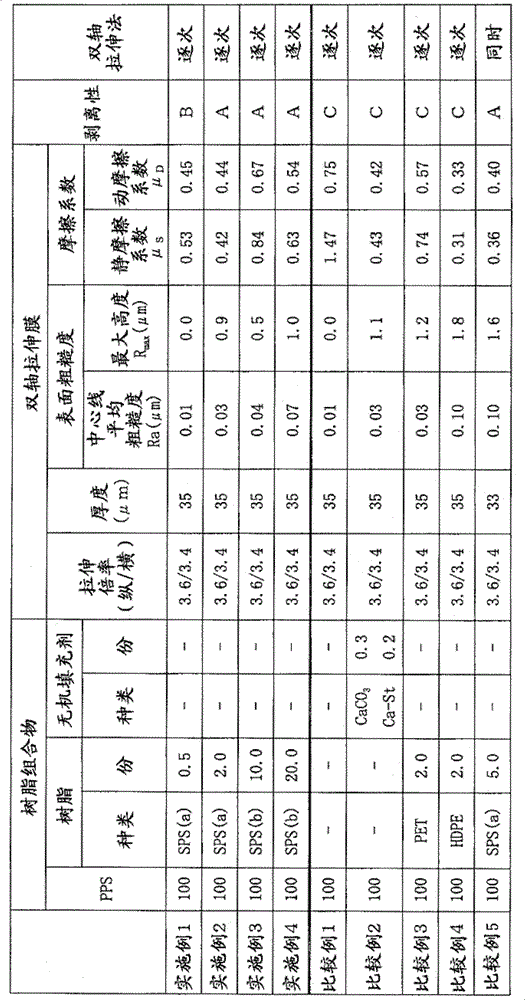

Examples

Embodiment 1

[0135] The linear polyphenylene sulfide powder (melt viscosity 160Pa s) is supplied to the extruder, melted and extruded in the form of strips, and the strips are immersed in a cooling water tank to solidify, and then the strips are cut into pellets with a granulator ( Hereinafter referred to as "PPS particles").

[0136]On the other hand, the syndiotactic polystyrene ["XAREC (registered trademark) S104" manufactured by Idemitsu Kosan Co., Ltd.; MFR = 15 g / 10 minutes, Tm = 271 ° C measured under a temperature of 300 ° C and a load of 2.16 kgf ] particles (hereinafter referred to as "SPS particles (a)") were pre-dried by maintaining at 80°C for 3 hours.

[0137] The SPS particles (a) were added in a ratio of 0.5 parts by mass based on 100 parts by mass of the PPS particles, and mixed using a mixer to prepare a particle mixture. This granule mixture was put into an extruder with a diameter of 35 mm, melt-kneaded at 310° C., and formed into pieces from a T-die (die width = 300 m...

Embodiment 2

[0140] Except having changed the ratio of this SPS particle (a) into 2.0 mass parts from 0.5 mass part, it carried out similarly to Example 1, and produced the biaxially stretched film. The results are shown in Table 1. (Cut-off value when measuring surface roughness = 0.08mm)

Embodiment 3

[0142] Except that the particles of syndiotactic polystyrene were changed from the particles (a) of XAREC (registered trademark) S104 manufactured by Idemitsu Kosan Co., Ltd. to XAREC (registered trademark) 90ZC (rrrr stereo = 98%, temperature MFR = 9 g / 10 minutes, Tm = 272 ° C) particles measured at 300° C. and a load of 1.20 kgf (hereinafter referred to as “SPS particles (b)”), and the ratio thereof was changed from 0.5 parts by mass to 10.0 parts by mass A biaxially stretched film was produced in the same manner as in Example 1 except for 2 parts. The results are shown in Table 1. (Cut-off value when measuring surface roughness = 0.25mm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com