Fuel cell metal bipolar plate carbon chromium gradient coating and preparation method

A metal bipolar plate, fuel cell technology, applied in battery electrodes, metal material coating process, coating and other directions, can solve problems such as corrosion current and contact resistance reduction, reduce contact resistance, improve corrosion resistance, improve Effect of battery output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

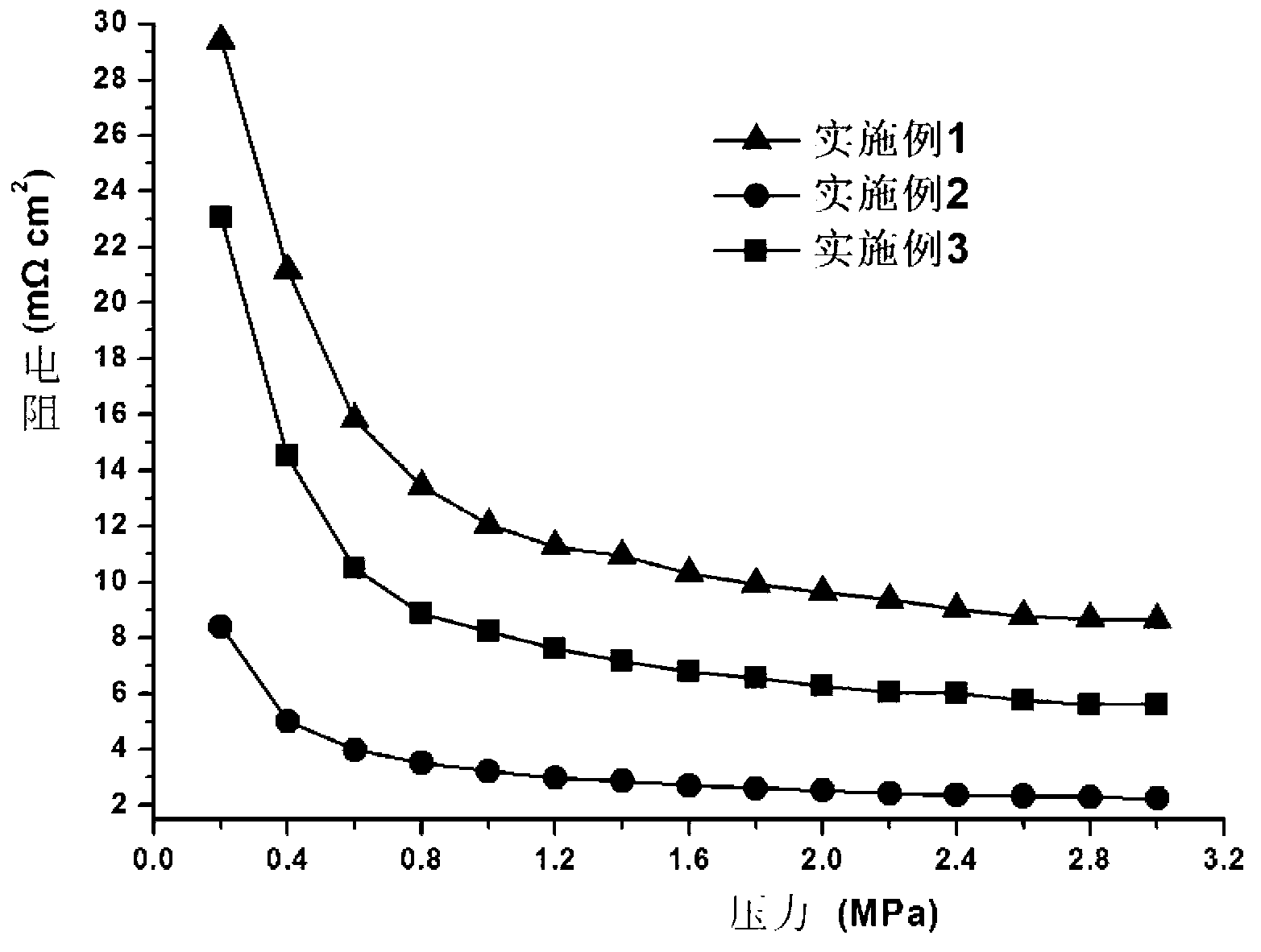

Embodiment 1

[0029] This embodiment is implemented under the following conditions of implementation and technical requirements:

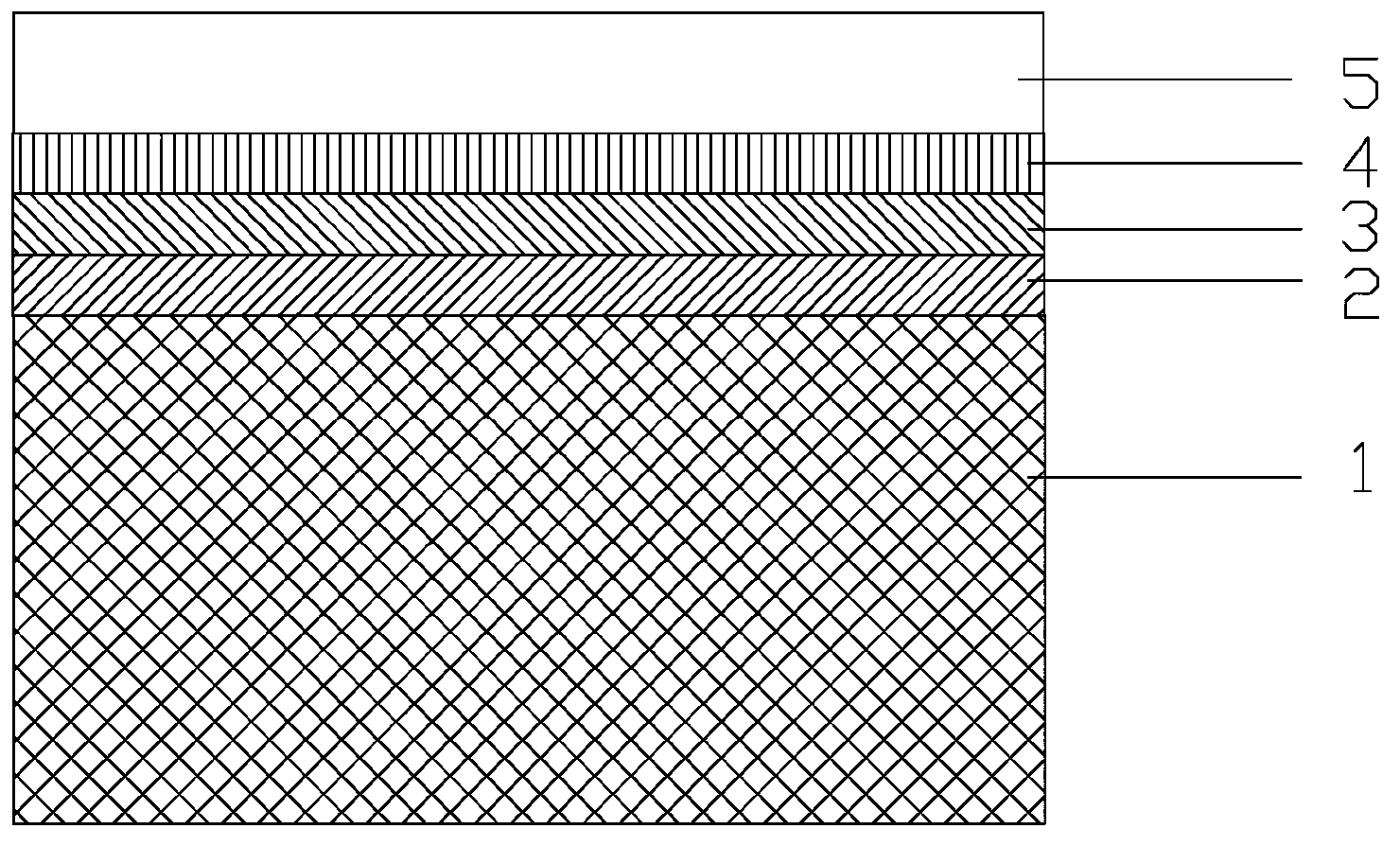

[0030] UDP850 unbalanced magnetron sputtering ion plating coating equipment is used to prepare carbon-chromium step coating. The equipment is equipped with 4 magnetron targets evenly distributed on the side wall of the coating chamber, and two chromium targets and two carbon targets are arranged opposite to each other. Put the 304 stainless steel and 316 stainless steel samples into the vacuum chamber after cleaning and drying, and install them on the rotating sample holder. Vacuum to 3.0×10 -5 torr, enter argon gas, apply bias to -300V, perform ion cleaning on the surface of the sample to remove the passivation film on the stainless steel surface; then adjust the substrate bias to -80V, chromium target current 4A, deposit Cr bottom layer for 5min; For the transition layer, turn on the carbon target, the current gradually increases to 4A, the chromium target cu...

Embodiment 2

[0032]UDP850 unbalanced magnetron sputtering ion plating coating equipment is used to prepare carbon-chromium step coating. The equipment is equipped with 4 magnetron targets evenly distributed on the side wall of the coating chamber, and two chromium targets and two carbon targets are arranged opposite to each other. Put the 304 stainless steel and 316 stainless steel samples into the vacuum chamber after cleaning and drying, and install them on the rotating sample holder. Vacuum to 3.0×10 -5 torr, enter argon gas, apply bias voltage to -500V, perform ion cleaning on the surface of the sample to remove the passivation film on the stainless steel surface; then adjust the substrate bias voltage to -60V, chromium target current 6A, deposit Cr bottom layer for 10min; redeposition For the transition layer, turn on the carbon target, the current gradually increases to 6A, the chromium target current gradually decreases to 1A, and the time is 45 minutes; then keep the carbon target ...

Embodiment 3

[0034] UDP850 unbalanced magnetron sputtering ion plating coating equipment is used to prepare carbon-chromium step coating. The equipment is equipped with 4 magnetron targets evenly distributed on the side wall of the coating chamber, and two chromium targets and two carbon targets are arranged opposite to each other. Put the 304 stainless steel and 316 stainless steel samples into the vacuum chamber after cleaning and drying, and install them on the rotating sample holder. Vacuum to 3.0×10 -5 torr, enter argon gas, apply bias voltage to -700V, perform ion cleaning on the surface of the sample to remove the passivation film on the stainless steel surface; then adjust the substrate bias voltage to -70V, chromium target current 8A, deposit Cr bottom layer for 15min; redeposition For the transition layer, turn on the carbon target, the current gradually increases to 8A, the chromium target current gradually decreases to 1A, and the time is 60 minutes; then keep the carbon target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com