Polymer, organic electroluminescence element material, composition for organic electroluminescence element, organic electroluminescence element, display device, and lighting device

An organic electric field and light-emitting element technology, applied in the field of polymers, can solve the problems of difficult stacking, poor driving stability, not reaching the practical level, etc., and achieve the effects of high driving stability, high hole transport capacity, and high electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1)

[0375] (Synthesis Example 1) Synthesis of Polymer 1

[0376] Synthesis of Intermediate 1

[0377]

[0378] 4,4'-(1,3-Dimethylbutylidene)diphenol (15g, 55.48mmol), triethylamine (22.46g, 221.92mmol), dichloromethane (150ml) were added under nitrogen atmosphere, and the mixture was dissolved at 0 Stir at °C. To this was added trifluoromethanesulfonic acid anhydride (37.56 g, 133.16 mmol), and the mixture was stirred at room temperature for 6 hours. Water and 1N hydrochloric acid were added to the reaction mixture, followed by extraction with dichloromethane. The organic layer was washed with a mixed solution of water and 1N hydrochloric acid, washed with brine, dried over magnesium sulfate, and concentrated under reduced pressure. The residue was purified by silica gel column chromatography (hexane / dichloromethane=3 / 1) to obtain Intermediate 1 (19.1 g, yield 64%).

[0379] Synthesis of Intermediate 2

[0380]

[0381] A suspension of Intermediate 1 (19.1 g, 35.73 mmol)...

Synthetic example 2)

[0395] (Synthesis Example 2) Synthesis of Polymer 2

[0396]

[0397] Aniline (0.6575 g, 0.706 mmol), monomer 2 (0.0457 g, 0.234 mmol), monomer 3 (2.000 g, 3.647 mmol), sodium tert-butoxide (2.24 g, 23.3 mmol), toluene (19 ml) were added The inside of the system was fully replaced with nitrogen and heated to 60°C (solution A). To a solution of tris(dibenzylideneacetone)dipalladium chloroform complex (0.075g, 0.0729mmol) in 5ml of toluene was added tri-tert-butylphosphine (0.118g, 0.584mmol) and warmed to 60°C (solution B). Solution B was added to solution A in a nitrogen stream, and the reaction was heated under reflux for 2.0 hours. The disappearance of aniline and monomers 2 and 3 was confirmed, and 4,4'-dibromobenzene (1.104 g, 3.538 mmol) was added. The mixture was heated to reflux for 40 minutes, the reaction solution was allowed to cool, and the reaction solution was added dropwise to 300 ml of ethanol to precipitate polymer 2 into crystals.

[0398] The filtered p...

Embodiment 1)

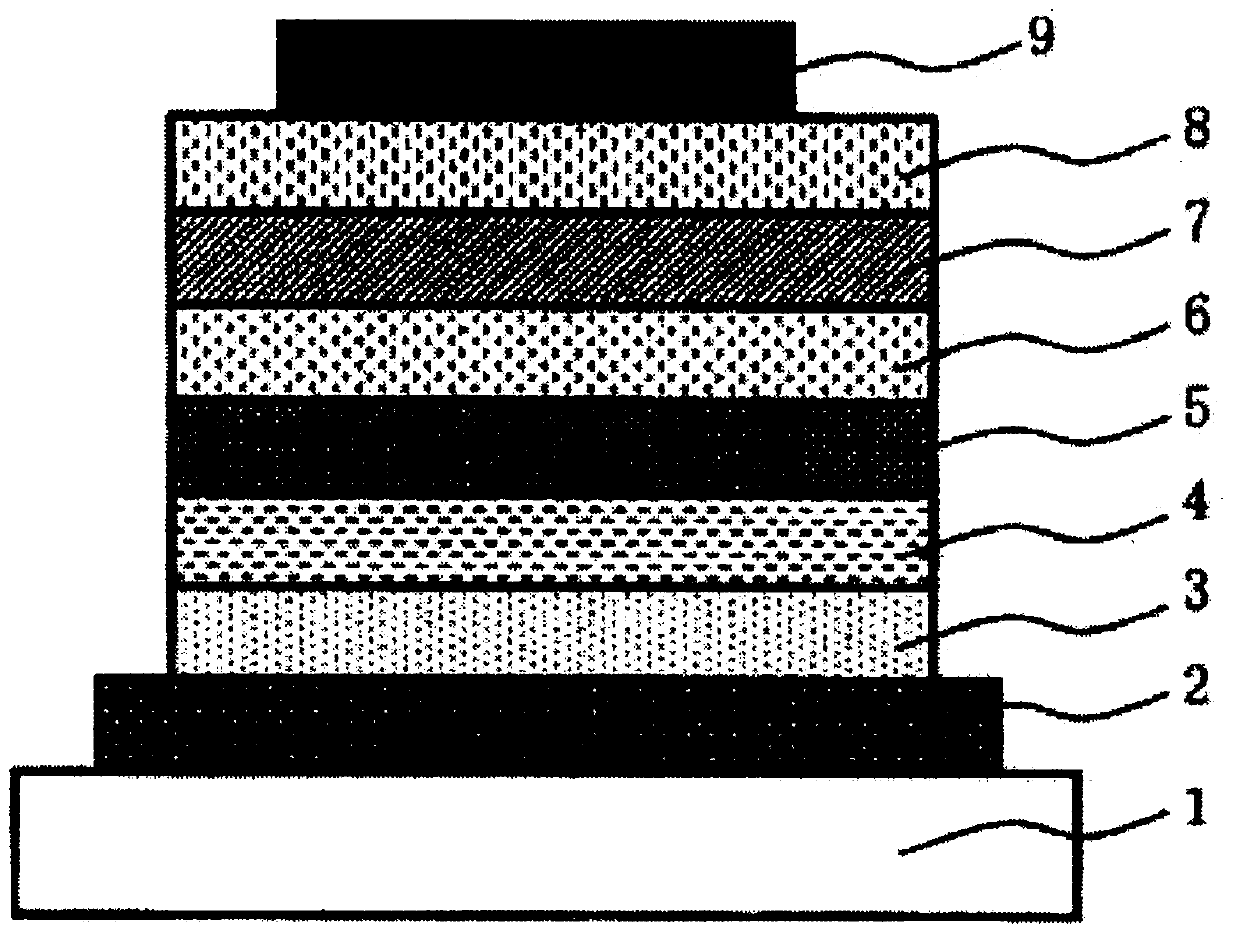

[0404] make figure 1 The organic electroluminescent element shown.

[0405] The anode 2 is formed by patterning a product (sputtered product, sheet resistance 15Ω) with a 150 nm transparent conductive film of indium tin oxide (ITO) formed on a glass substrate into stripes with a width of 2 mm using a common photolithography technique. The patterned ITO substrate was cleaned in the order of ultrasonic cleaning with acetone, water cleaning with pure water, and ultrasonic cleaning with isopropanol, dried under nitrogen flow, and finally, ultraviolet ozone cleaning was performed.

[0406] First, a polymer (weight average molecular weight: 70,000, number average molecular weight: 40,000) represented by the following structural formula (H8) and 4-isopropyl-4'-methyldiphenyl iodide represented by the structural formula (A1) were prepared A coating solution for forming a hole injection layer of tetrakis(pentafluorophenyl)borate and ethyl benzoate. This coating liquid was formed int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com