Endoplasmic slow release composite fertilizer and its preparation method

A compound fertilizer and endoplasmic technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of secondary pollution of slow-release materials, high additional costs, and poor integration, and achieve improved soil structure properties and large production capacity , to solve the effect of poor fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

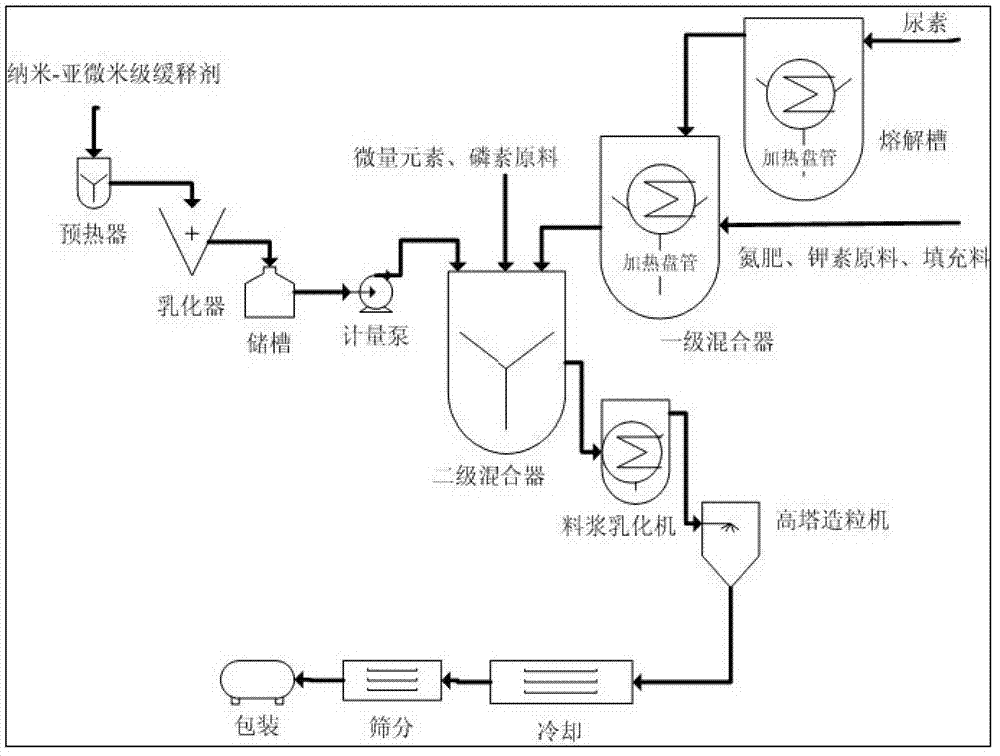

Method used

Image

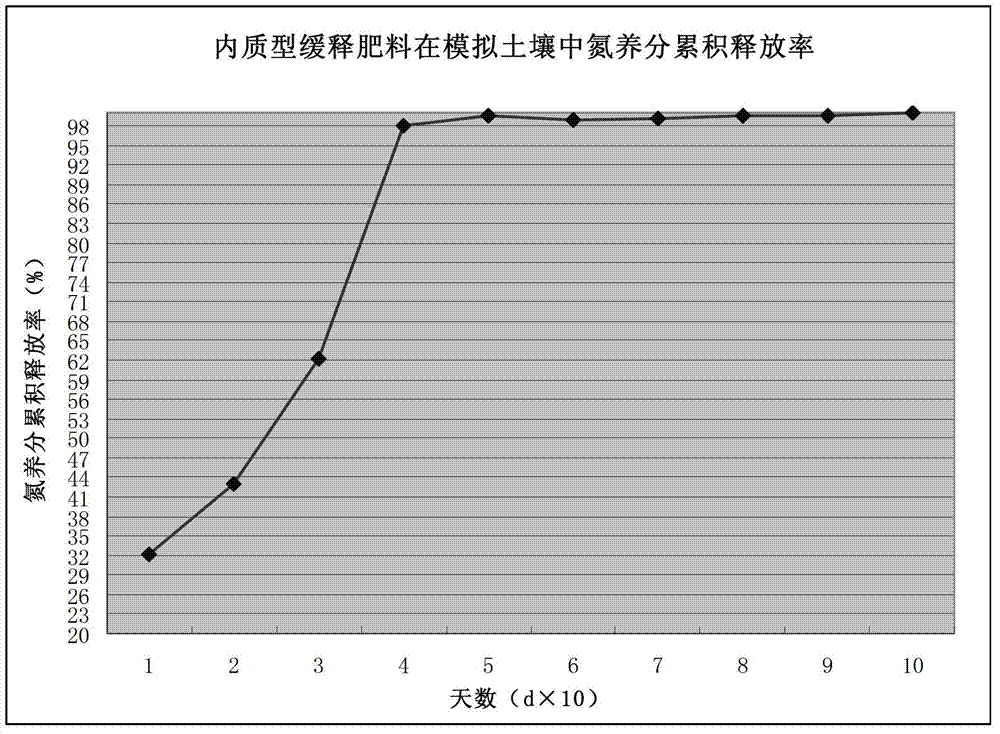

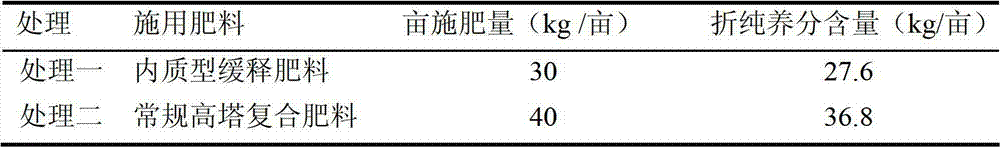

Examples

Embodiment 1

[0046] (1) Preparation steps:

[0047] a) Add 50kg of urea into the melting tank and heat and melt to obtain urea melt;

[0048] b) Put the molten urine into the primary mixer, and add 15kg of potassium chloride, 5kg of ammonium chloride, and 19.5kg of dolomite powder for primary mixing, and the mixing temperature is 104°C~114°C;

[0049] c) Add the nano-scale humic acid mixed polymer into the mixing device with a water bath temperature of 65°C, pass it into the emulsifier after the temperature is constant, emulsify at a constant temperature of 65°C for 8 minutes, and then enter the water bath constant temperature storage tank for standby;

[0050] d) The mixture after primary mixing is added to the second-stage mixer of the high tower, and 1.5kg of pretreated nano-scale humic acid mixed polymer, 8kg of monoammonium phosphate, and 1kg of the mixture of copper sulfate and zinc sulfate are added, Perform secondary mixing at a temperature between 98°C and 100°C to make a fluid s...

Embodiment 2

[0058] (1) Preparation steps:

[0059] a) Add 45kg of urea into the melting tank and heat and melt to obtain urea melt;

[0060] b) Put the molten urine into the primary mixer, and add 18kg of potassium chloride and 10kg of dolomite powder for primary mixing. The mixing temperature is 100°C~110°C;

[0061] c) Add the nano-scale waste plastic-starch mixture into the mixing device with a water bath temperature of 75°C, pass it into the emulsifier after the temperature is constant, emulsify at a constant temperature of 75°C for 10 minutes, and then enter the water bath constant temperature storage tank for standby;

[0062] d) The mixture after primary mixing is added to the second-stage mixer of the high tower, and 2kg of pretreated nano-scale waste plastic-starch mixed polymer, 24kg of monoammonium phosphate, 0.3kg of ferrous sulfate, and 0.3kg of sulfuric acid are added Zinc and 0.4kg of manganese sulfate are mixed at a temperature between 95°C and 100°C to make a fluid solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com