Electrochemical gaging method for content of metal vanadium in crude oil

A determination method and electrochemical technology, applied in the petroleum field, can solve the problems of long enrichment time, poisoning, application limitation, etc., and achieve the effects of good selectivity, cheap analytical instruments and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

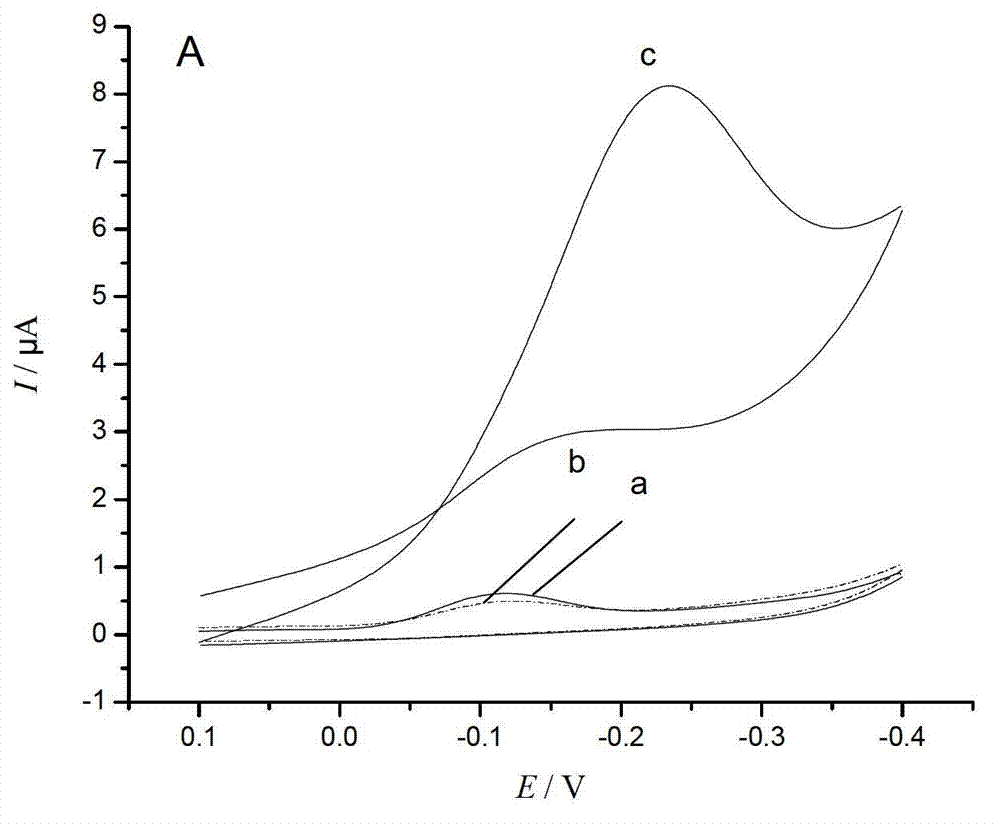

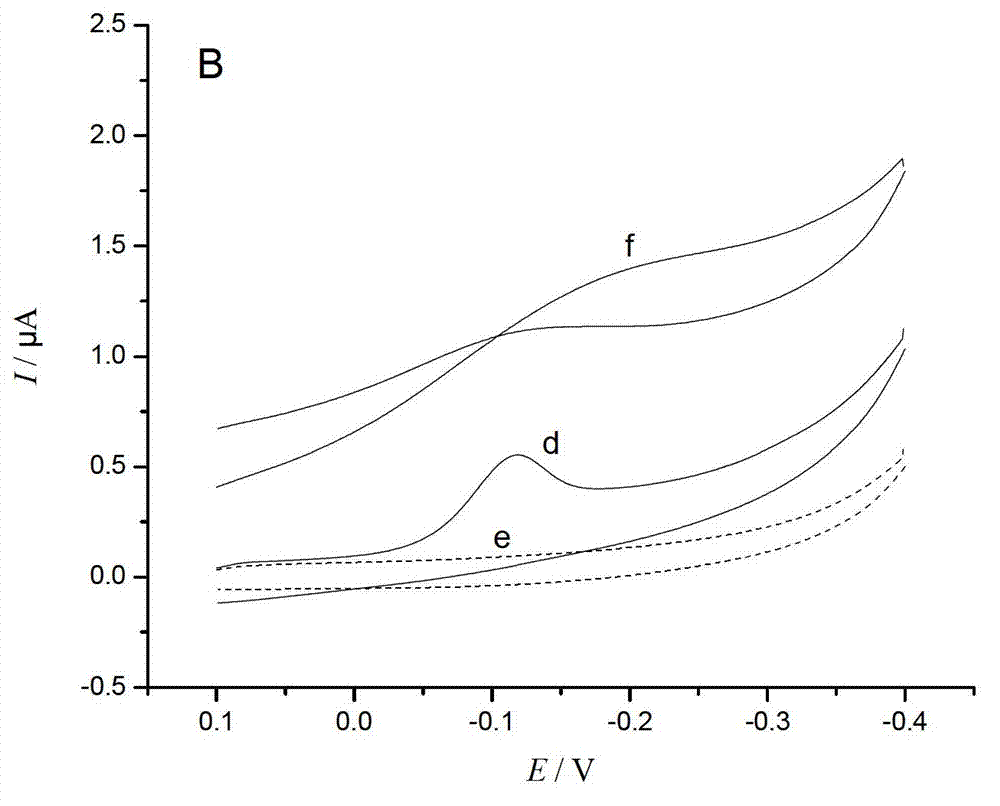

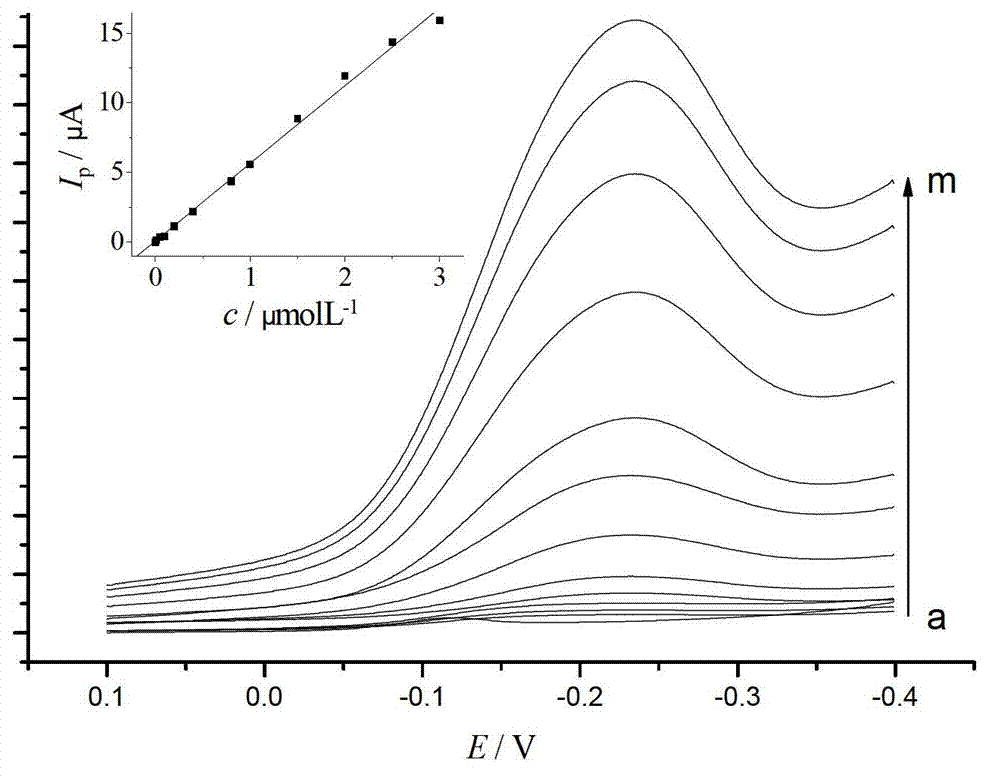

[0023] The present invention will be described in detail below in conjunction with the drawings.

[0024] The water used in the experiment was double distilled water, and the reagents used in the experiment included ammonium metavanadate (NH 4 VO 3 ), 4-(2-pyridylazo)-resorcinol (PAR), potassium bromate (KBrO 3 ), sulfuric acid (H 2 SO 4 ), etc. are analytical grade.

[0025] Step 1. The diameter is 10-20nm, the length is 1-2μm, and the purity is> 95% of the carbon nanotubes and liquid paraffin are mixed in a mortar with a mass ratio of 3:2, grind into a uniform paste, fill in a plastic tube with a diameter of 1.6mm, compact it, and use copper wire to lead as a wire to obtain carbon nanotubes Tube paste electrode MWCNT-PE, grind and polish the surface of MWCNT-PE on weighing paper, and store at room temperature;

[0026] Step 2. Use MWCNT-PE as a working electrode, a saturated calomel electrode as a reference electrode, and a platinum wire electrode as a counter electrode to form a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com