Composite oxidizer and method for preparing high efficiency liquid chromatography eluate acetonitrile by using same

A technology of high performance liquid chromatography and composite oxidant, which is applied in the field of purification of chemical products, can solve the problems of long oxidation time, violent reaction, residual manganese salt, etc., and achieve the effect of saving reaction time, good oxidation effect and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

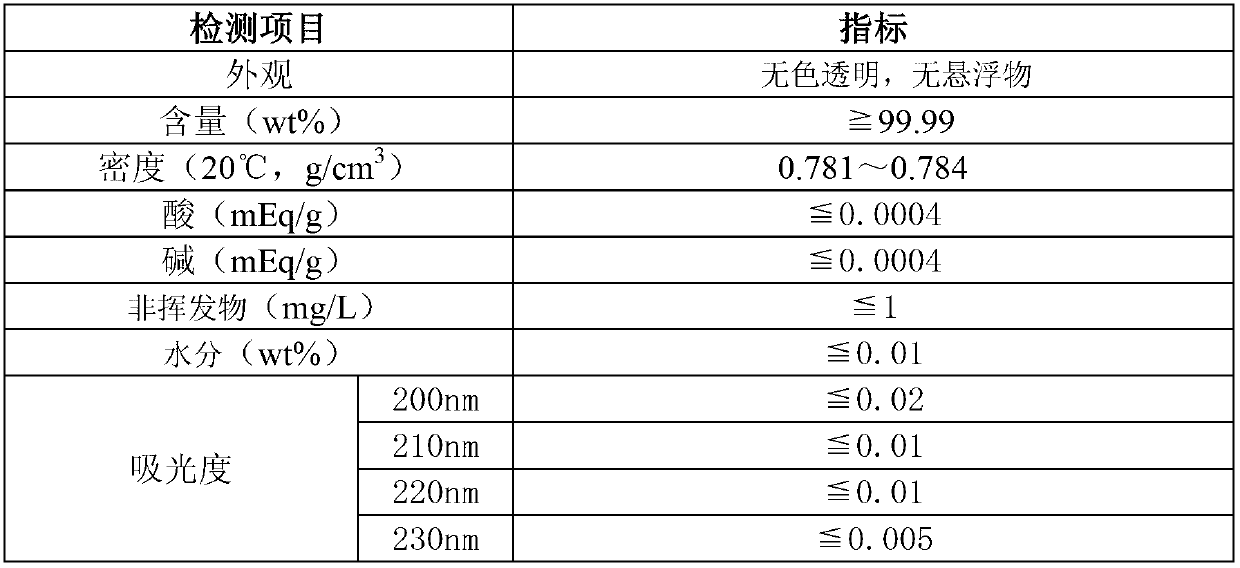

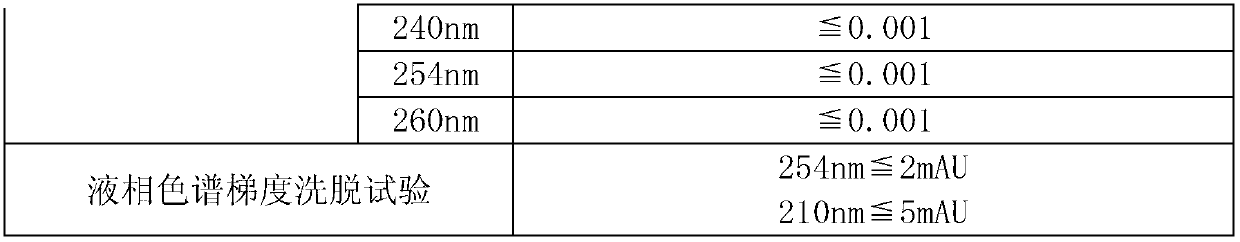

Image

Examples

Embodiment 1

[0027] A preparation method of high performance liquid chromatography eluent acetonitrile, the steps are as follows:

[0028] (1) The raw material acetonitrile (99.9% purity) is injected into the three-layer adsorption bed. The three-layer adsorption bed is composed of activated alumina layer, activated carbon layer and 3A molecular sieve layer in series from top to bottom. The specifications of the three layers are: long 1 meter, 1 meter high, 1.2 meters wide;

[0029] The outlet channel of each layer of adsorption bed is equipped with an opening connected with a water pump to generate negative pressure to control the flow rate of acetonitrile;

[0030] Among them, the activated alumina layer, activated carbon layer, and 3A molecular sieve layer are respectively filled with activated alumina with a particle size of 0.2mm, activated carbon with a particle size of 0.2mm, and 3A molecular sieve. 1 / 2 of the height;

[0031] After acetonitrile is injected into the activated alum...

Embodiment 2

[0036] A preparation method of high performance liquid chromatography eluent acetonitrile, the steps are as follows:

[0037] (1) The raw material acetonitrile (99.5% purity) is injected into the three-layer adsorption bed. The three-layer adsorption bed is composed of activated alumina layer, activated carbon layer, and 3A molecular sieve layer in series from top to bottom. The specifications of the three layers are: long 0.5 meters, 0.5 meters high, 0.6 meters wide;

[0038] The outlet channel of each layer of adsorption bed is equipped with an opening connected with a water pump to generate negative pressure to control the flow rate of acetonitrile;

[0039] Among them, the activated alumina layer, activated carbon layer, and 3A molecular sieve layer are respectively filled with activated alumina with a particle size of 0.2mm, activated carbon with a particle size of 0.2mm, and 3A molecular sieve. 1 / 2 of

[0040] After acetonitrile is injected into the activated alumina l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com