Method for preparing polyolefin micro-porous film

A polyolefin microporous film and polyolefin technology, applied in flat products, household utensils, and other household utensils, etc., can solve problems such as rough electrode surface, diaphragm pressure, affecting battery cycle life, service efficiency and safety characteristics, etc. , to achieve fast absorption of electrolyte, small change in air permeability, and meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

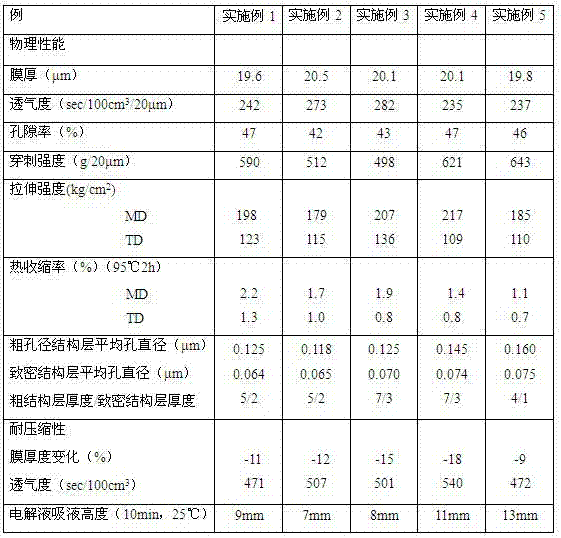

Examples

Embodiment 1

[0025] The preparation method of the polyolefin microporous membrane of the present embodiment comprises the steps:

[0026] (a), 25 parts by mass of ultra-high molecular weight polyethylene (weight average molecular weight 1×10 6 ), add 0.025 parts by mass of antioxidant 1010 {tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester} and 0.5 parts by mass of nucleating Silica powder, then added to a twin-screw extruder (diameter 110mm, L / D=52), 75 parts by mass of liquid paraffin was injected from the middle of the twin-screw extruder through a metering pump, at 210°C, 100r / min Melting and kneading under the same conditions to prepare polyolefin homogeneous melt;

[0027] (b) The polyolefin homogeneous melt is extruded from the flat film die at the front end of the extruder to form a molding melt, and the molding melt is drawn out with a cooling roller A whose temperature is adjusted to 18°C. Roll A is contacted and cooled for 30s. After surfa...

Embodiment 2

[0032] The preparation method of the polyolefin microporous membrane of the present embodiment comprises the steps:

[0033] (a), 10 parts by mass of ultra-high molecular weight polyethylene (weight average molecular weight 1.5×10 6 ), 17 parts by mass of polypropylene (weight average molecular weight 2.5×10 5 ) and 3 parts by mass of terpolymerized polypropylene (weight average molecular weight 1×10 5 ), add 0.03 parts by mass of antioxidant 1010 {tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester} and 0.6 parts by mass of nucleating Silica powder, then added to a twin-screw extruder (diameter 110mm, L / D=52), 70 parts by mass of liquid paraffin was injected from the middle of the twin-screw extruder through a metering pump, at 235°C, 100r / min Melting and kneading under the same conditions to prepare polyolefin homogeneous melt;

[0034] (b) The polyolefin homogeneous melt is extruded from the flat film die at the front end of the extrud...

Embodiment 3

[0039] The preparation method of the polyolefin microporous membrane of the present embodiment comprises the steps:

[0040] (a), 12 parts by mass of ultra-high molecular weight polyethylene (weight average molecular weight 1.5×10 6 ) and 15 parts by mass of high-density polyethylene (weight-average molecular weight 4×10 5 ), add 0.027 parts by mass of antioxidant 1010 {tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester} and 0.54 parts by mass of nucleating Silica powder, then added to a twin-screw extruder (diameter 110mm, L / D=52), 73 parts by mass of liquid paraffin was injected from the middle of the twin-screw extruder through a metering pump, at 210°C, 100r / min Melting and kneading under the same conditions to prepare polyolefin homogeneous melt;

[0041] (b) The polyolefin homogeneous melt is extruded from the flat film die at the front end of the extruder to become a molding melt, and the molding melt is drawn out with a cooling ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com