Solar battery assembly, up-conversion piece of solar battery sheet and preparation method of up-conversion piece

A technology of solar cells and conversion parts, which is applied in the direction of electrical components, circuits, photovoltaic power generation, etc., can solve the problems of low conversion efficiency on the conversion layer, reduce the light transmittance of the conversion layer, and the difficulty of realizing the conversion layer, so as to improve the photoelectric conversion Efficiency, reduced specular reflection, and improved light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

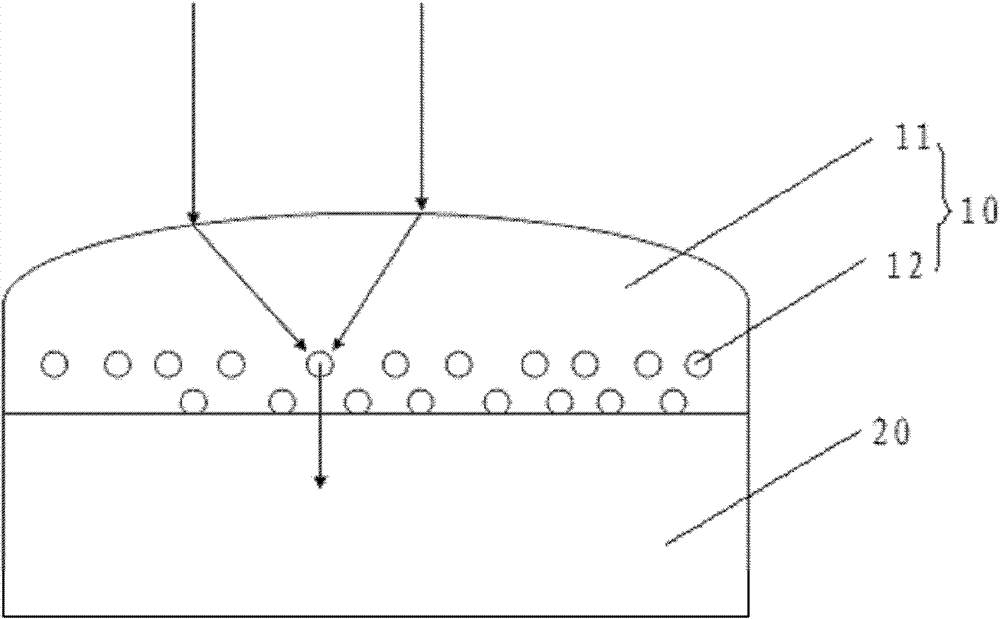

[0044] The preparation method of the up-converter 10 according to the embodiment of the present invention includes: uniformly mixing the phosphor powder and the glass frit, pouring it into a mold, and cooling to make the up-converter 10 of the solar cell with a convex upper surface.

[0045] It should be noted that, in the case of selecting an inorganic glass material to form the transparent glass substrate 11, the glass frit can use either a sol (such as water glass, etc.) or a glass powder. When using a sol, the phosphor powder 11 After mixing with the glass frit, pour it into the mold for hydrolysis and drying. When using glass powder, after mixing the phosphor powder 11 with the glass frit, you only need to heat it into a melt, pour it into the mold and cool it down. In the case of selecting organic glass material to form the transparent glass substrate 11, it is only necessary to combine the phosphor body 11 with the organic glass material (i.e. one of polymethyl methacryl...

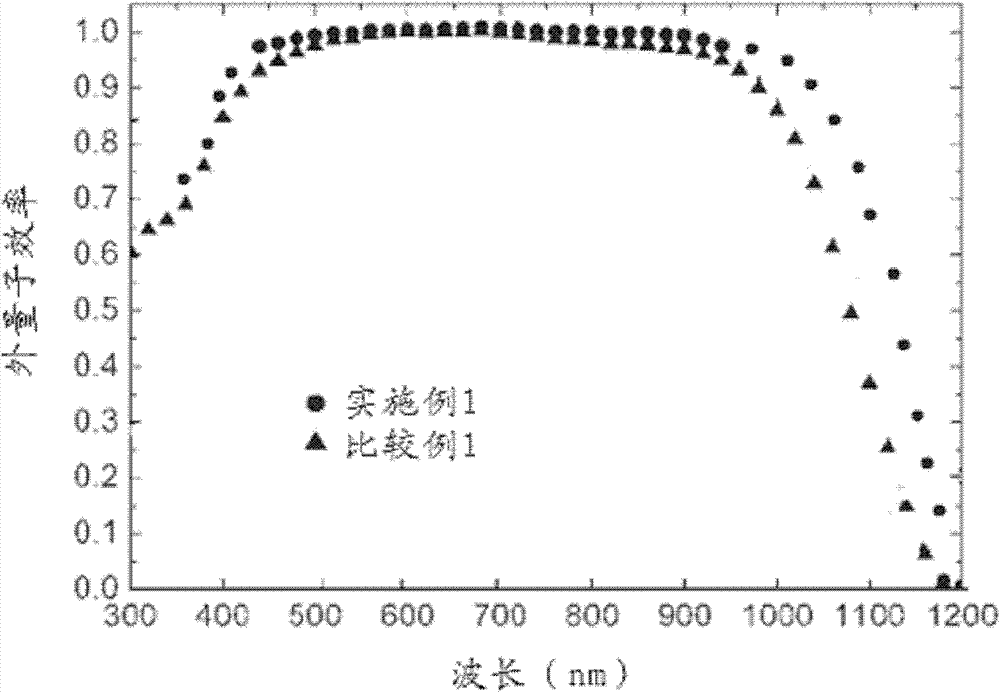

Embodiment 1

[0050] I) Raw materials

[0051] Phosphor powder: NaYF4:Er in powder state for commercial use

[0052] Raw material of transparent scattering film layer: tetraethyl orthosilicate

[0053] Glass frit: Silicate glass powder

[0054] II) Preparation of upconverters

[0055] First, take 10g of NaYF4:Er powder, soak it in an aqueous solution of tetraethyl orthosilicate for 2 hours, take it out and dry it, so as to obtain NaYF4:Er powder covered with a transparent silicon dioxide film.

[0056] Thereafter, mix the above-mentioned powder with 1 kg of silicate glass powder material evenly, melt it at a high temperature above 450 degrees Celsius, pour it into a mold, and cut it into small pieces of 125mm×125mm after cooling. The mold has an arc-shaped inner surface with a curvature radius of 35-40 mm, and a maximum depth of 20 mm.

[0057] III) Preparation of solar cell modules

[0058] The up-conversion element obtained above is packaged on a single solar cell by known means, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com