Method for preparing colorless corundum monocrystal

A single crystal and corundum technology, applied in the field of crystal growth, can solve problems such as difficulty in meeting high-performance requirements, unstable crystal single crystal quality, and limited crystal size, so as to ensure crystal growth quality, shorten processing time, and reduce stress defects. effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

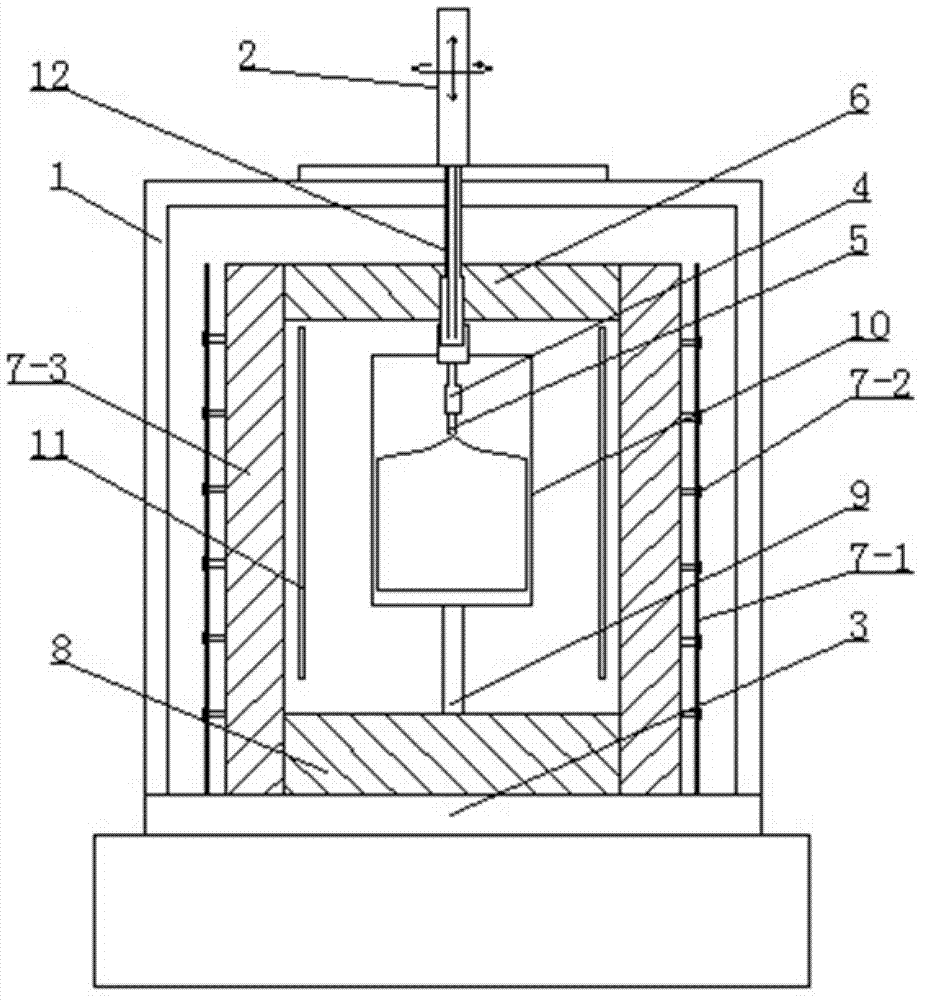

Method used

Image

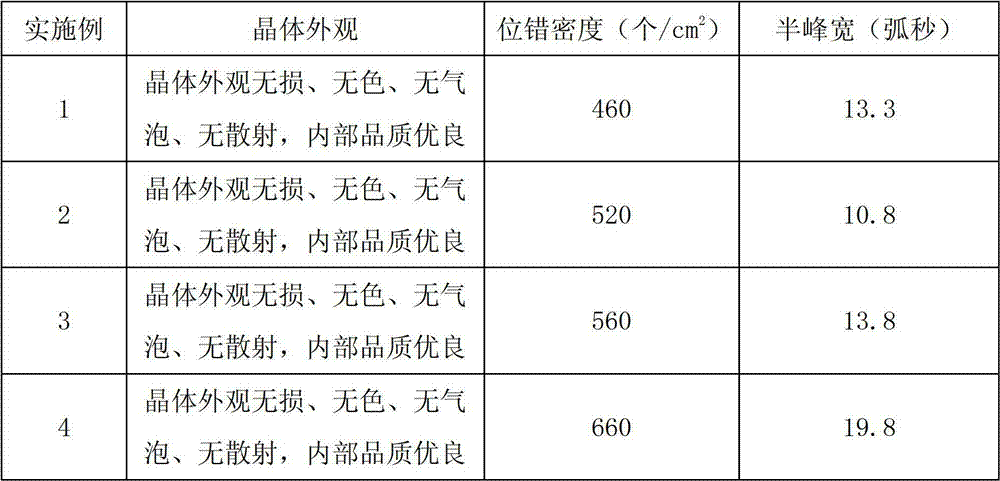

Examples

Embodiment 1

[0034] The preparation method of the colorless corundum single crystal of this embodiment includes the following sequential steps:

[0035] 1) Raw material pretreatment: Place a cylindrical polycrystalline alumina block with a diameter of Φ180mm, a height of 240mm, and a weight of 30.2kg in the center of the crucible in the crystal growth furnace. The polycrystalline alumina block accounts for 95% of the total feeding. , and then 1.59kg of polycrystalline alumina pellets with a purity of Φ1mm greater than 99.996% were used to fill the gaps in the crucible, with a total weight of 31.79kg; -3 pa) at a rate of 600°C / h to 2150°C, the alumina reaches a molten state and remains in a vacuum environment;

[0036] 2) Cleaning and seed crystal: uniformly cool down at a rate of 20°C / h for 4 hours to cool the temperature of the alumina solution to 2070°C, and place the seed crystal (the diameter of the seed crystal is Φ10mm, the length is 120mm, and the crystal orientation is a direction ...

Embodiment 2

[0042] The preparation method of the colorless corundum single crystal of this embodiment includes the following sequential steps:

[0043] 1) Raw material pretreatment: Place a cylindrical polycrystalline alumina block with a diameter of Φ200mm, a height of 250mm, and a weight of 38.2kg in the center of the crucible in the crystal growth furnace. The polycrystalline alumina block accounts for 93% of the total feed. , and then 2.87kg of polycrystalline alumina particles with a purity of Φ2mm greater than 99.996% were evenly stirred, and the gaps in the crucible were filled, with a total weight of 41.07kg; -3 pa) at a rate of 800°C / h to 2150°C, the alumina reaches a molten state and remains in a vacuum environment;

[0044] 2) Cleaning and seeding: uniform cooling at a rate of 25°C / h for 3.1 hours to cool the temperature of the alumina solution to 2070°C, and the seed crystal (the diameter of the seed crystal is Φ12mm, the length is 130mm, and the crystal orientation is a direc...

Embodiment 3

[0050] The preparation method of the colorless corundum single crystal of this embodiment includes the following sequential steps:

[0051] 1) Raw material pretreatment: Place a cylindrical polycrystalline alumina block with a diameter of Φ250mm, a height of 340mm, and a weight of 59.2kg in the center of the crucible in the crystal growth furnace. The polycrystalline alumina block accounts for 92% of the total input , and then use 5.14kg of 5mm polycrystalline alumina pellets with a purity greater than 99.996% to fill the gap in the crucible, with a total weight of 64.34kg; -3 pa) at a rate of 500°C / h to 2150°C, the alumina reaches a molten state and remains in a vacuum environment;

[0052] 2) Cleaning and seeding: uniform cooling at a rate of 15°C / h for 5.1 hours to cool the temperature of the alumina solution to 2070°C, and the seed crystal (the diameter of the seed crystal is Φ16mm, the length is 140mm, and the crystal orientation is a direction ± 0.1°) to sink to 40mm be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com