Horizontally-arranged cylinder rolling type aerobic fermentation apparatus with heat exchange function

A technology of aerobic fermentation and heat exchange, which is applied in the preparation of organic fertilizers, fertilization devices, organic fertilizers, etc., can solve the problems of difficult solid-liquid separation of biogas slurry, long fermentation time, and large area, and improve fermentation efficiency. and effect, high fermentation efficiency, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

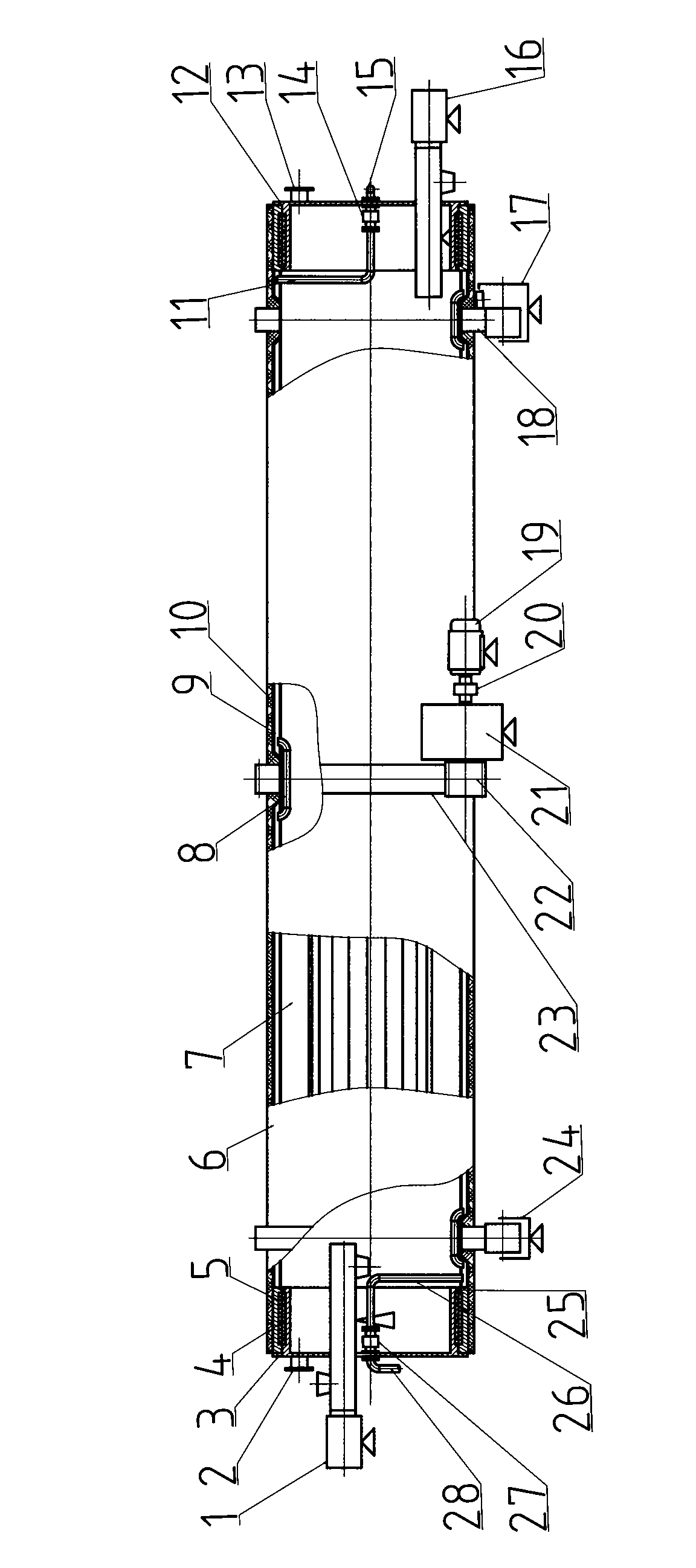

[0033] Referring to the accompanying drawings, the horizontal cylindrical fermenter 6 is supported on the right supporting wheel group 17 and the left supporting wheel group 24, and the two supporting wheel groups support the supporting steel rings 18 on both sides of the cylindrical fermenting tank 6, and the left supporting wheel is adjusted. The wheel set 24 makes the feed end of the cylindrical fermenter 6 higher than the discharge end, the angle between the axis of the cylindrical fermenter 6 and the horizontal plane is adjustable from 0 to 5 degrees, and the stop wheel on the right supporting wheel set 17 prevents The cylinder moves along the axis.

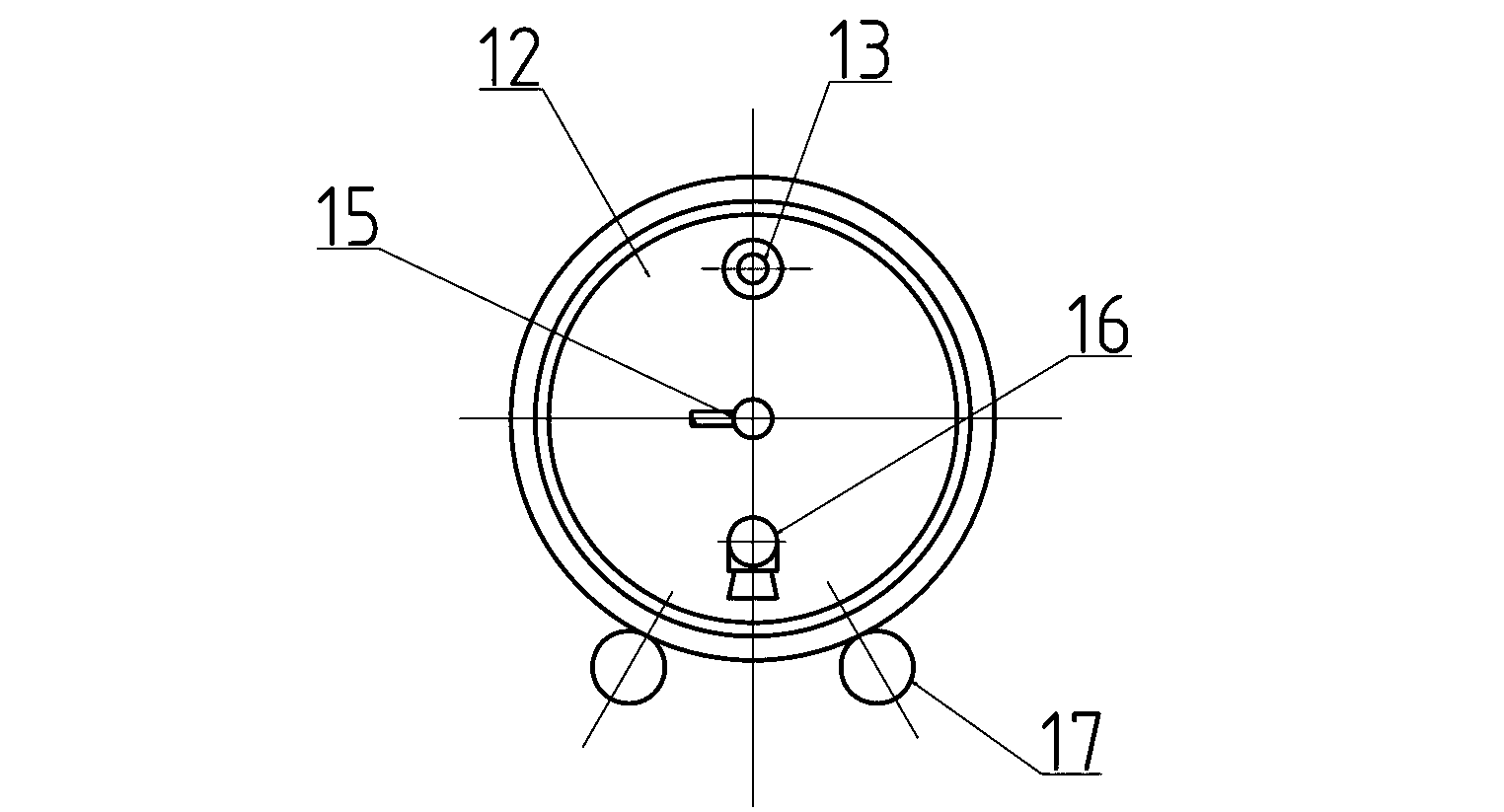

[0034] A bearing outer ring 5 and a bearing inner ring 4 are respectively housed in the left and right ends of the cylindrical fermenter 6, and the left and right side covers 3, 12 are installed in the middle of the bearing inner ring 4 respectively. Bearing inner 4 and outer ring 5, left and right side covers 3, 12 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com