Selective reduction reaction system

A reaction system and selective technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high cost and low reduction and conversion efficiency, and achieve the effect of low cost, low failure rate, and prevention of theft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

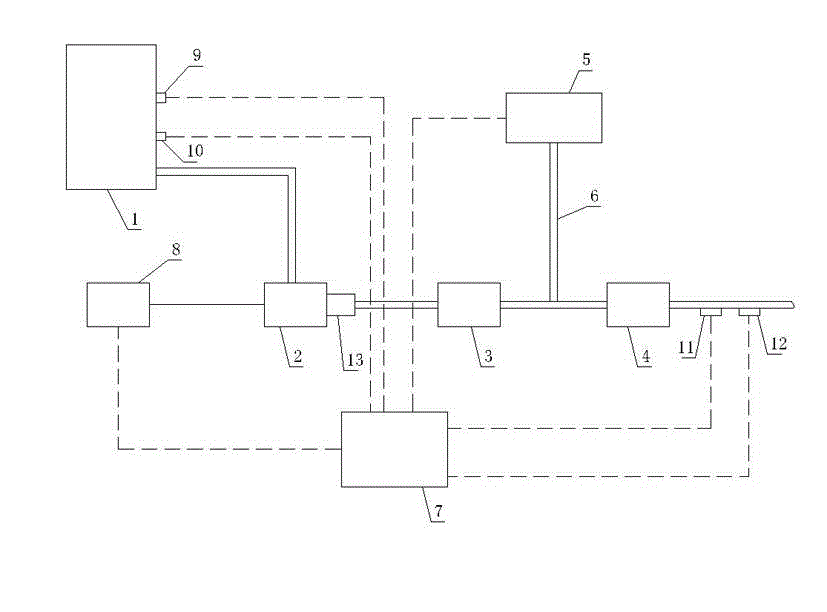

[0018] Such as figure 1 As shown, the selective reduction reaction system of the present invention includes a urea tank 1, a urea pump 2, a urea nozzle 3, an SCR catalytic converter 4 installed sequentially through pipelines, an engine control unit 5, an engine exhaust pipe 6, a control Unit 7, wherein the engine exhaust pipe 6 is installed on the pipeline between the urea nozzle 3 and the SCR catalytic converter 4, the urea pump 2 is driven by a DC motor 8, and the DC motor 8 is controlled by the control unit 7, and the control unit 7 and the The engine control units 5 communicate through CAN in real time. The urea tank 1 is equipped with a urea temperature sensor 9 and a urea liquid level sensor 10 connected to the control unit 7 . Exhaust gas temperature sensor 11, nitrogen oxide sensor 12.

[0019] Wherein, the urea pump 2 has a filter 13 and a heating blanket, and the filter 13 is a two-stage filter. The urea nozzle 3 is an atomizing nozzle with an orifice shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com