Preparation method of compatible polylactic acid fire retardant

A polylactic acid and compatibility technology, applied in the field of preparation of compatible polylactic acid flame retardants, can solve problems such as poor compatibility and poor heat resistance, and achieve the effects of rapid synthesis, easy product and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

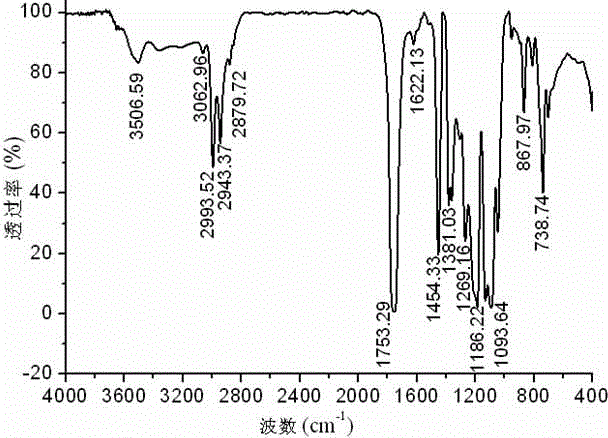

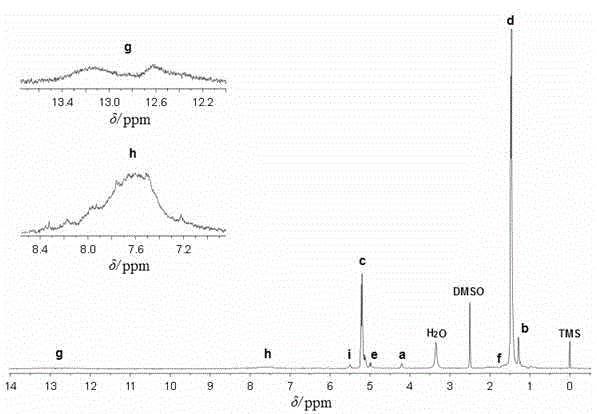

Embodiment 1

[0030] Using D, L-LA, o-phenylenediamine analogue F (that is, biphenyltetramine, see the aforementioned structural formula F) as raw materials, according to the ratio of substances n (D,L-LA): n (Biphenyltetramine) = 200:1 mixed evenly, after 120°C, 4000Pa, 5h of pre-polymerization and water removal treatment to obtain intermediate I, adding catalyst zinc oxide (0.5% by mass of intermediate I), at temperature Melt polycondensation at 160°C and pressure 70Pa for 5h. After the reaction, the product was dissolved in chloroform at normal temperature, purified by methanol precipitation, and vacuum-dried to obtain a white powdery benzimidazole-based compatible polylactic acid flame retardant. The structure of the polymer was confirmed by infrared spectroscopy (see figure 1 ), H NMR spectrum (see figure 2 ), gel permeation chromatography and other polymer characterization methods confirmed that the intrinsic viscosity [η] is 0.5049 dL / g, and the nitrogen-containing compatible pol...

Embodiment 2

[0036] Using D, L-LA, o-phenylenediamine analogue E (see the aforementioned structural formula E) as raw materials, according to the ratio of substances n (D,L-LA): n (o-phenylenediamine analogue E) = 160:1 mixed evenly, after prepolymerization at 140°C, 4000Pa, 8h to get intermediate I, add catalyst stannous oxide (mass percentage is 0.7% of intermediate I ), control the temperature at 160°C and the pressure at 80Pa, and react for 6h. After the reaction, the product was dissolved in chloroform, purified by methanol precipitation, and vacuum-dried to obtain a white powdery benzimidazole-based compatible polylactic acid flame retardant. In the same way as in Example 1, the structure of the polymer is confirmed by polymer characterization methods such as infrared spectroscopy, hydrogen nuclear magnetic resonance spectroscopy, and gel permeation chromatography. The intrinsic viscosity [η] is 1.0977 dL / g, and the nitrogen-containing base phase synthesized by this method The cap...

Embodiment 3

[0038] Take L-LA, o-phenylenediamine D 1 (R 2 = H, see the aforementioned structural formula D) as raw material, according to the ratio of substance n (L-LA): n (o-phenylenediamine D 1 ) = 50:1 mixed evenly, after 130°C, 4000Pa, 10h of pre-polymerization treatment to remove water, intermediate I was obtained, and the catalyst stannous octoate (0.5% by mass of intermediate I) was added at a temperature of 165°C and a pressure of 90Pa Next, melt polycondensation for 3h. After the reaction, the product is dissolved, precipitated and purified, and vacuum-dried to obtain a white powdery benzimidazole-based compatible polylactic acid flame retardant. In the same way as in Example 1, the structure of the polymer is confirmed by polymer characterization methods such as infrared spectroscopy, hydrogen nuclear magnetic resonance spectroscopy, and gel permeation chromatography. The intrinsic viscosity [η] is 0.6842 dL / g, and the nitrogen-containing base phase synthesized by this me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com