Preparation method of yeast microsphere magnetic composite material surface imprinted adsorbent

A magnetic composite material, surface imprinting technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., to achieve strong compatibility, reduce non-specific adsorption, and remove completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

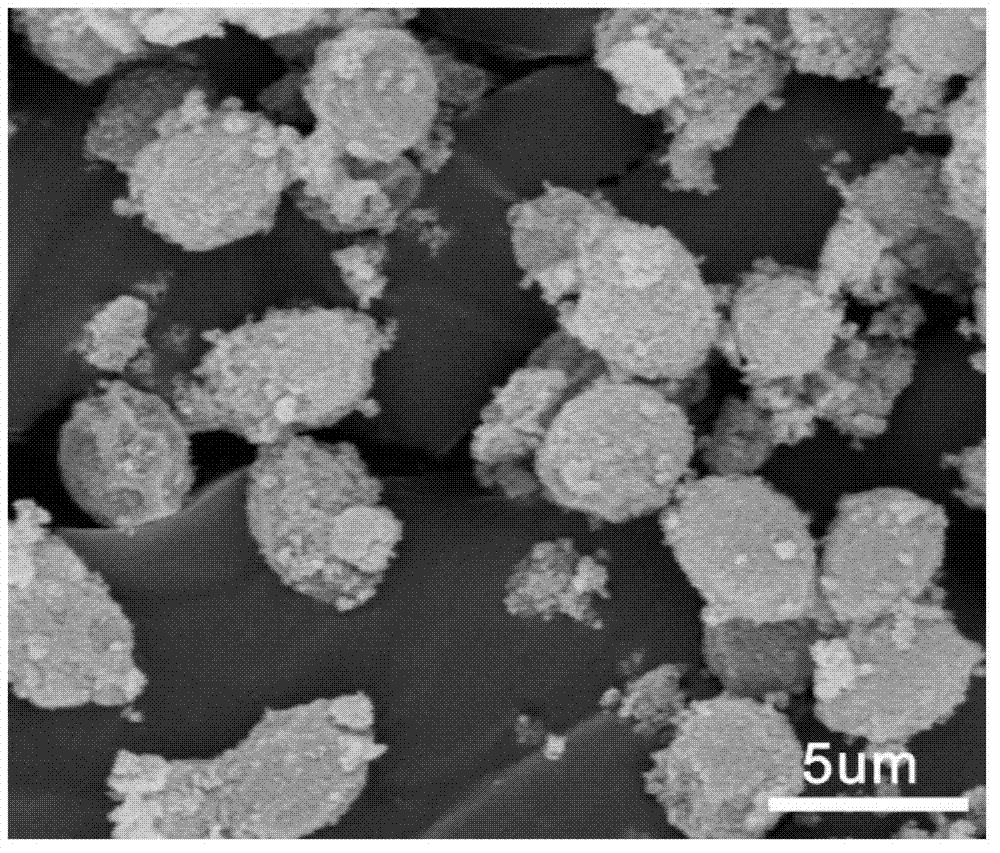

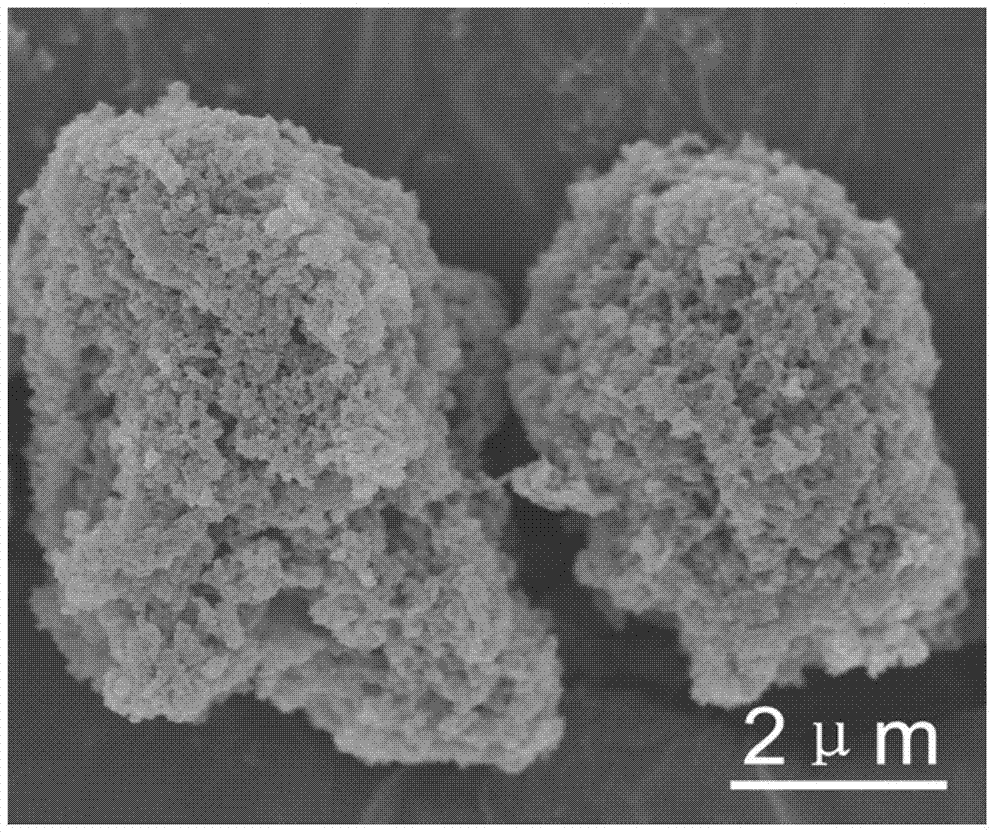

Image

Examples

Embodiment 1

[0032] Taking the preparation of beta-cypermethrin as an example of yeast microsphere magnetic composite material surface imprinted adsorbent as a template molecule, the preparation method comprises the following steps:

[0033] Step 1: Preparation of Yeast Microsphere Magnetic Composite

[0034] Step 1.1: Weigh 10 g of yeast microspheres and disperse them in 350 mL of distilled water to form a yeast solution with a solid-to-liquid ratio of 1:35 g / mL; add 14 g of ferric chloride to the yeast solution, and stir mechanically at room temperature for 3 hours. Ventilate nitrogen to evacuate oxygen, add 10g ferrous chloride, make the mass ratio of yeast microspheres to ferric chloride and ferrous chloride 1:1.4:1, stir mechanically for 60 minutes until the temperature rises to 78°C, continue Stir mechanically and react for 25 minutes to prepare a yeast ferric chloride ferrous chloride dispersion solution.

[0035]1.2) Add 16g of sodium hydroxide to the dispersion solution in step 1...

Embodiment 2

[0043] Taking the preparation of beta-cypermethrin as an example of yeast microsphere magnetic composite material surface imprinted adsorbent as a template molecule, the preparation method comprises the following steps:

[0044] Step 1: Preparation of Yeast Microsphere Magnetic Composite

[0045] Step 1.1: Weigh 10 g of yeast microspheres and disperse them in 300 mL of distilled water to form a yeast solution with a solid-to-liquid ratio of 1:30 g / mL; add 12 g of ferric chloride to the yeast solution, and stir mechanically at room temperature for 3 hours. Negative nitrogen is evacuated oxygen, adds 9.5g ferrous chloride, makes the mass ratio of yeast microsphere and ferric chloride, ferrous chloride be 1:1.2:0.95, other operation is identical with embodiment 1 in this step, Prepare yeast ferric chloride ferrous chloride dispersion solution.

[0046] Step 1.2: Add 14g of sodium hydroxide to the dispersion solution in step 1.1), the mass ratio of yeast microspheres to sodium hy...

Embodiment 3

[0054] Taking the preparation of beta-cypermethrin as an example of yeast microsphere magnetic composite material surface imprinted adsorbent as a template molecule, the preparation method comprises the following steps:

[0055] Step 1: Preparation of Yeast Microsphere Magnetic Composite

[0056] Step 1.1: Weigh 10 g of yeast microspheres and disperse them in 500 mL of distilled water to form a yeast solution with a solid-to-liquid ratio of 1:50 g / mL; add 15 g of ferric chloride to the yeast solution, and stir mechanically at room temperature for 3 hours. Nitrogen evacuates oxygen, adds 11g ferrous chloride, makes the mass ratio of saccharomycete microsphere and ferric chloride, ferrous chloride be 1:1.5:1.1, other operations in this step are identical with embodiment 1, prepare into yeast ferric chloride ferrous chloride dispersion solution.

[0057] Step 1.2: Add 18g of sodium hydroxide to the dispersion solution in step 1.1), the mass ratio of yeast microspheres to sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com