Precious metal particle dispersed toughened composite thermal barrier coating and its preparation method

A technology of thermal barrier coating and precious metals, applied in the direction of metal material coating process, coating, mechanical equipment, etc., to achieve the effect of improving heat insulation effect, improving fracture toughness, and wide working temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

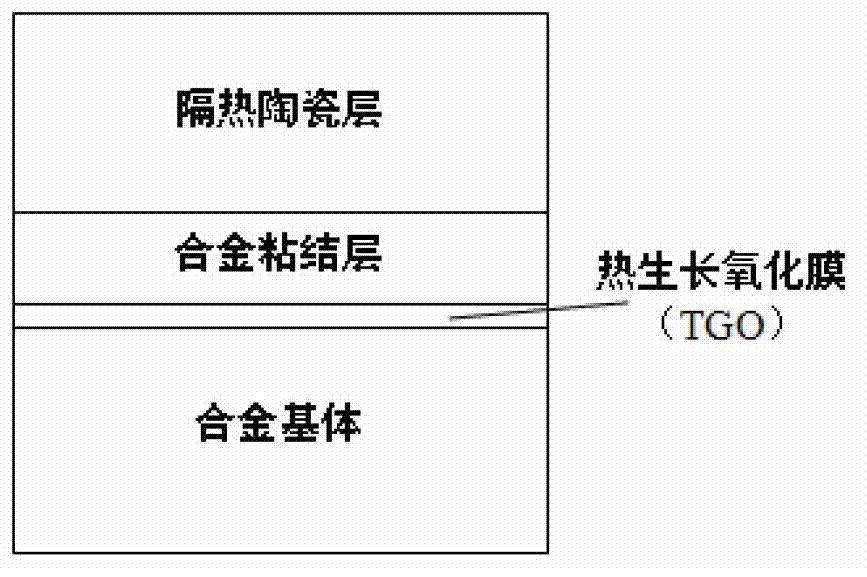

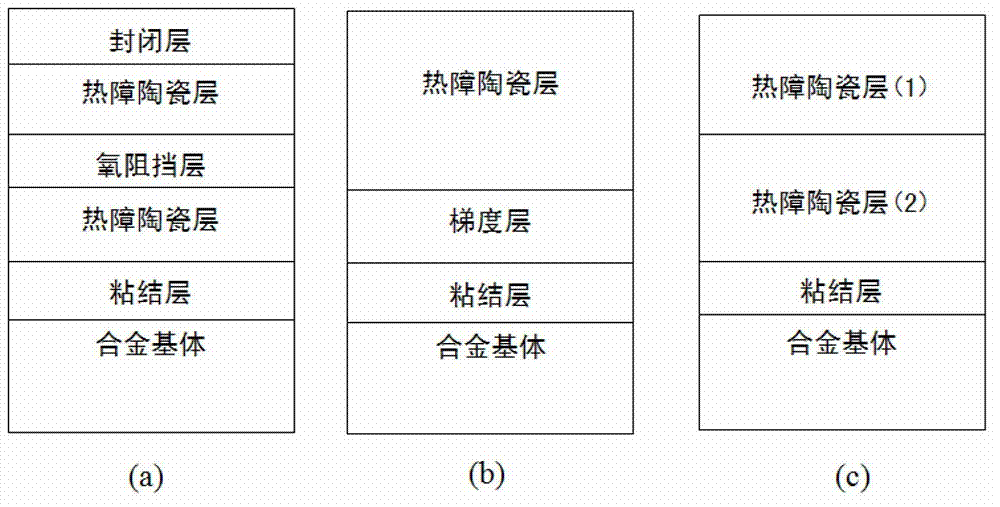

Problems solved by technology

Method used

Image

Examples

Embodiment 1

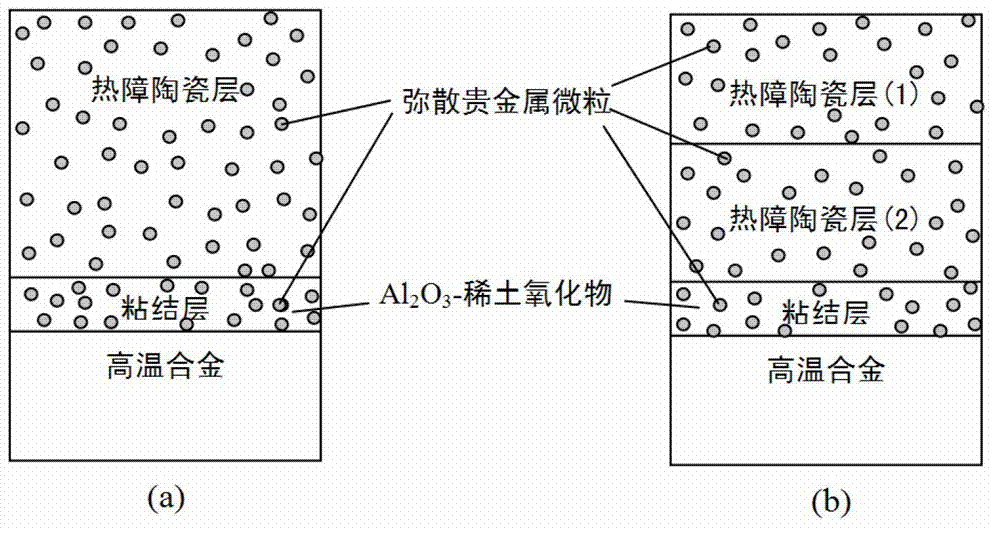

[0038] Example 1: Toughened by hot-pressed filtration sintering dispersed Pt particles (Al 2 o 3 -YAG) / YSZ composite thermal barrier coating

[0039] Preparation of Al 2 o 3 -YAG(Y 3 al 5 o 12 )-Pt particle composite sol-gel, in which the content of solid particles is 60% (mass percentage), the content of oxides converted from sol-gel is 40% (mass percentage), and the particle size of Pt particles is 20~500nm , its content is 1% (mass percentage); the content of YAG is 0.5% (mass percentage). After uniform mixing, it is coated on the surface of nickel-based superalloy, the thickness is controlled at 5mm, and it is sintered into Al by hot-press filtration. 2 o 3 - YAG-Pt composite bonding layer.

[0040] Prepare YSZ-Pt particle composite sol-gel, in which the solid particle content is 60% (mass percentage), the sol-gel converted oxide content is 40% (mass percentage), and the particle size of Pt particles is 20~500nm , and its content is 1% (mass percentage). After...

Embodiment 2

[0042] Example 2: Toughening of dispersed Pt-20%Au particles by pressure microwave sintering (Al 2 o 3 -YAG) / YSZ composite thermal barrier coating

[0043] Preparation of Al 2 o 3 -YAG-(Pt-20%Au) microparticle composite sol-gel, wherein the content of solid particles is 60% (mass percentage), and the content of sol-gel converted to oxide is 40% (mass percentage), (Pt -20%Au) particle size is 20~500nm, its content is 1% (mass percentage); YAG content is 0.5% (mass percentage). After uniform mixing, it is coated on the surface of nickel-based superalloy, the thickness is controlled at 5mm, and it is sintered into Al by pressure microwave sintering. 2 o 3 -YAG-(Pt-20%Au) composite bonding layer.

[0044] -(Pt-20%Au) microparticle composite sol-gel, in which the proportion of solid particles is 60% (mass percentage), and the content of sol-gel converted to oxide is 40% (mass percentage), (Pt-20 %Au) particle size is 20~500nm, its content is 1% (mass percentage). After un...

Embodiment 3

[0046] Example 3: Toughened by pressure microwave sintering of dispersed Pt particles (Al 2 o 3 -YAG) / YSZ / La 2 Zr 2 o 7 Composite Thermal Barrier Coating

[0047] Preparation of Al 2 o 3 -YAG-Pt microparticle composite sol-gel, in which the content of solid particles is 60% (mass percentage), the content of sol-gel converted to oxide is 40% (mass percentage), and the particle size of Pt microparticles is 20~ 500nm, its content is 1% (mass percentage); YAG content is 0.5% (mass percentage). After uniform mixing, it is coated on the surface of nickel-based superalloy, the thickness is controlled at 5mm, and it is sintered into Al by pressure microwave sintering. 2 o 3 - YAG-Pt composite bonding layer.

[0048] Prepare YSZ-Pt microparticle composite sol-gel, in which the content of solid particles is 60% (mass percentage), the content of oxides converted from sol-gel is 40% (mass percentage), and the particle size of Pt microparticles is 20~ 500nm, its content is 1% (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com