Mineral powder for bituminous mixture and production method thereof

A technology for an asphalt mixture and a production method, which is applied in the field of mineral powder for asphalt mixture and its production, can solve the problems of increasing labor and equipment costs, difficult to guarantee quality, and many control points, and avoid equipment and labor costs. , cost saving, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

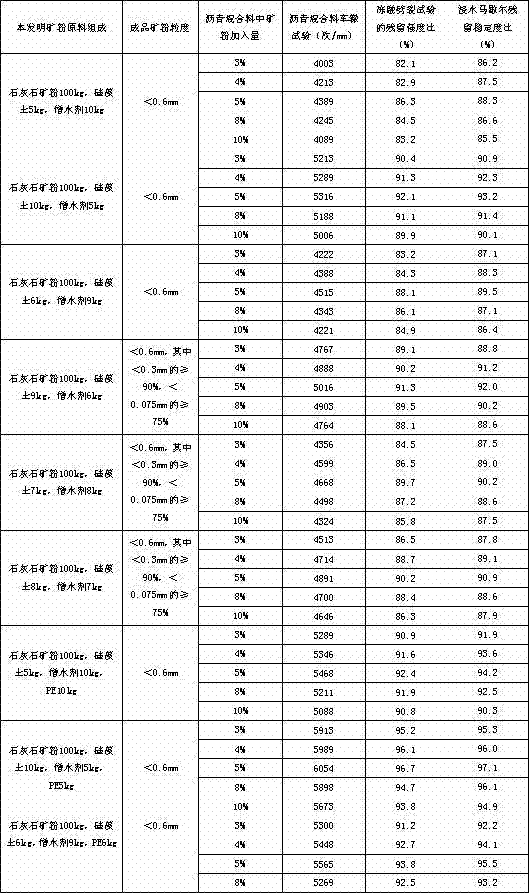

[0014] The raw materials are mixed and crushed until the particle size is less than 0.6mm, among which the particle size of less than 0.3mm is not less than 90%, and the particle size of less than 0.075mm is not less than 75%, so as to obtain the finished mineral powder with the same composition ratio as the raw materials. The raw materials are: limestone 100kg, diatoms 5kg-10kg of soil, 5kg-10kg of water-repellent, and 5kg-10kg of polymer used to modify the finished asphalt mixture. The diatomite in the finished mineral powder is 5% to 10% of the weight of the limestone, and the water repellent is 5% to 10% of the weight of the limestone. The polymers used to modify the finished asphalt mixture are optional components: 5% to 10% of the weight of limestone; add the above mineral powder to the asphalt mixture according to 3% to 10% of the mass of the asphalt mixture. Dry mixing temperature is about 170-190 degrees, dry mixing until uniform, oil-stone ratio and gradation remain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com