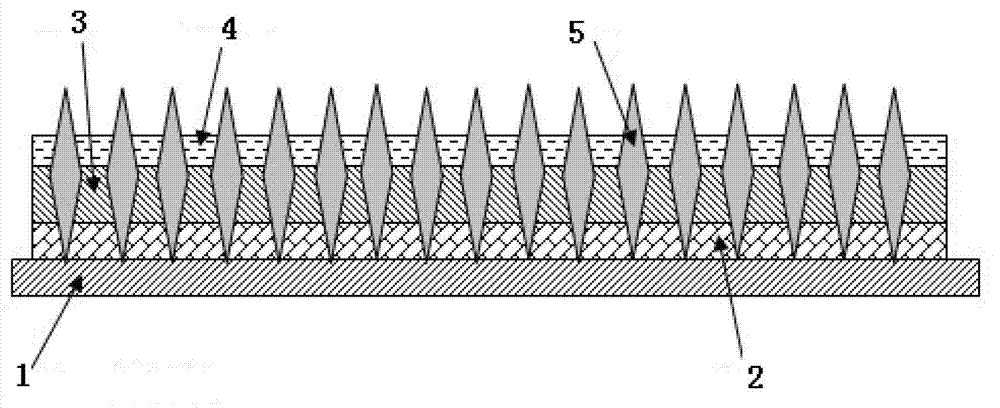

Film-based electrostatic sand-planting grinding belt and preparation method thereof

An electrostatic sand planting and grinding belt technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of low cutting force, poor chip removal performance, and short life of the grinding belt, so as to achieve the goal of not easy to drop sand, Strong chip removal ability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

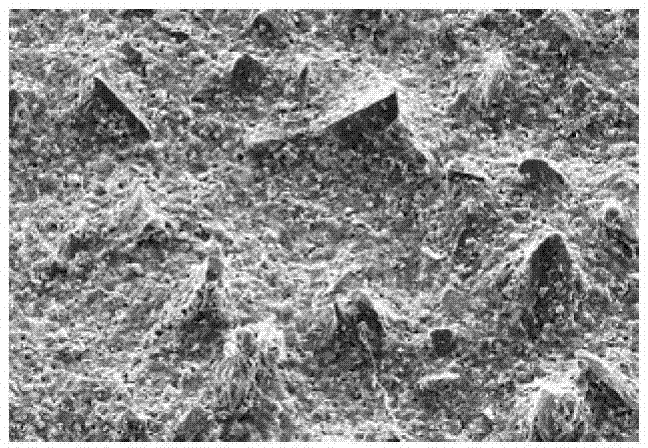

Method used

Image

Examples

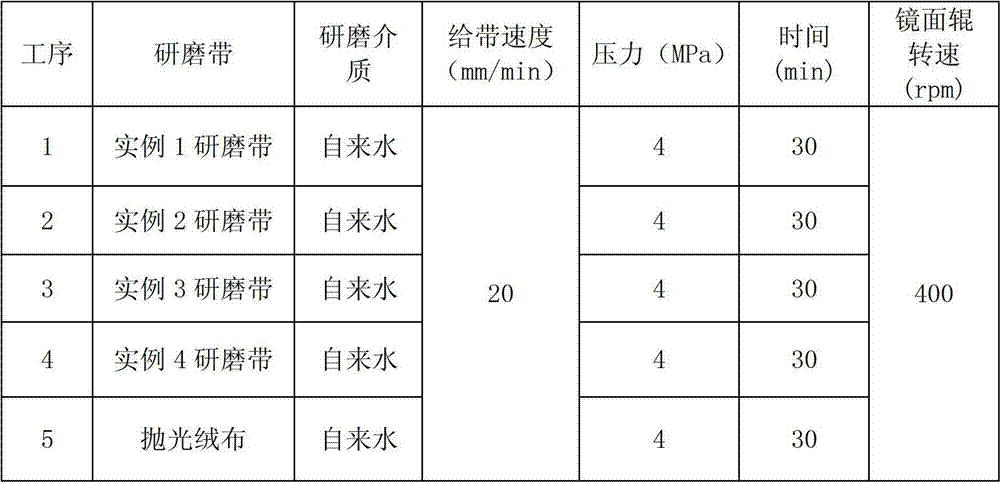

example 1

[0034] Step 1: Get 800g median particle diameter as calcium carbonate micropowder of 5 microns, 200g median particle diameter as calcium oxide micropowder of 10 microns, 3000g solid content of 30% polyester glue, 1500g solid content of 20% phenolic glue, 2400g ethyl acetate, 900g methyl ethyl ketone, 450g xylene, the above mixed solution is transferred to the dispersion tank of the ball mill, and it is fully dispersed for 48 hours by the ball mill, and then 5000g polyisocyanate curing agent (Shanghai Xinguang Chemical Factory) is added, stirred evenly to form a coating Cloth slurry. Use a roller coater to evenly coat the above-mentioned coating slurry on a film tape base with a thickness of 125 microns at a speed of 15m / min, and then adjust the amount of sand under the sand box to 150g / m 2 , The distance between the plates is 50 mm, the electrostatic field voltage is 60,000 volts, and the speed of the abrasive belt is set to 8 m / min. After the glue is applied, the base materia...

example 2

[0038] Step 1 gets 600g median particle diameter and is the calcium carbonate micropowder of 5 microns, 400g median particle diameter is the calcium oxide micropowder of 10 microns, 2000g solid content is 30% polyester glue, 2000g solid content is 20% phenolic glue, 2400g ethyl acetate, 900g methyl ethyl ketone, 450g xylene, the above mixed solution is transferred to the dispersion tank of the ball mill, and it is fully dispersed for 48 hours by the ball mill, and then 5000g polyisocyanate curing agent (Shanghai Xinguang Chemical Factory) is added, stirred evenly to form a coating Cloth slurry. Use a roll coater to evenly coat the above-mentioned coating slurry on a film tape base with a thickness of 125 microns at a speed of 15m / min, and then the base material passes through the sand planting machine after coating, and then the amount of sand under the sand box is adjusted. 120g / m 2 , The distance between the plates is 50mm, the voltage of the electrostatic field is 60,000 v...

example 3

[0042] Step 1 gets 1500g median particle diameter and is the calcium carbonate micropowder of 5 microns, 3000g solid content is the polyester glue of 30%, 1500g solid content is the phenolic glue of 20%, 2400g ethyl acetate, 900g methyl ethyl ketone, 450g xylene, The above mixed solution was transferred into the dispersion tank of the ball mill, fully dispersed by the ball mill for 48 hours, and then 5000g of polyisocyanate curing agent (Shanghai Xinguang Chemical Factory) was added, and stirred evenly to form a coating slurry. Use a roller coater to evenly coat the above-mentioned coating slurry on a film tape base with a thickness of 125 microns at a speed of 15m / min, and then adjust the amount of sand under the sand box to 100g / m 2 , The distance between the plates is 50mm, the voltage of the electrostatic field is 50,000 volts, and the speed of the abrasive belt is set to 8m / min. Alumina abrasives are planted on the adhesive layer of the base material, dried by hot air at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com