Anti-sticking water-based coating

A water-based coating and anti-sticking technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as easy to stick stains, surface cleanliness cannot be guaranteed, and achieve the effects of low environmental pollution, fast and efficient bronzing processing, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

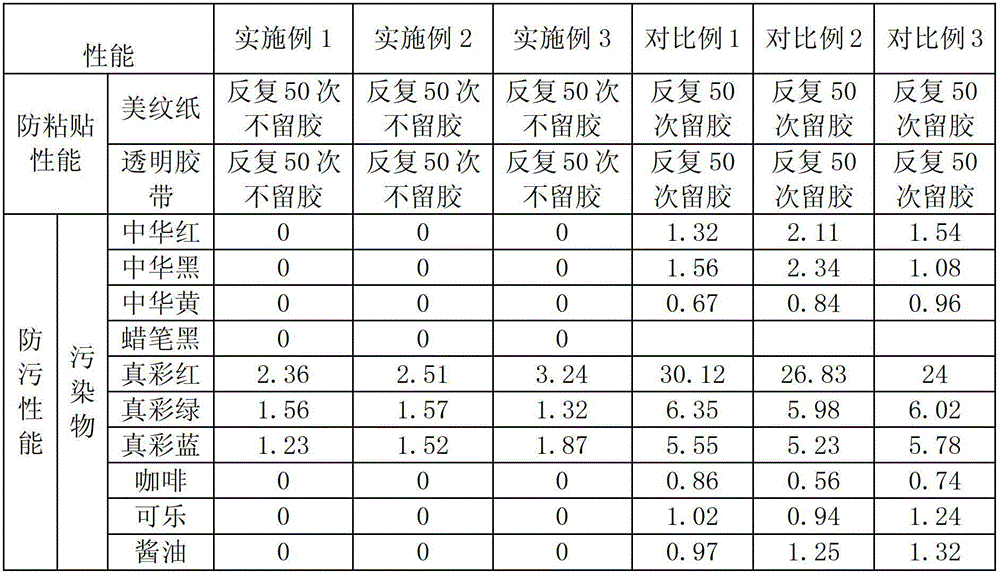

Embodiment 1

[0042] Polymer emulsion 80, methyl methacrylate 15, butyl acrylate 6, isooctyl acrylate 2, di-n-butyl maleate 3, hydroxyethyl acrylate 1, sodium dodecyl sulfonate 1.0, potassium persulfate 0.4, sodium acetate 0.2, hydrophobic agent 10, fluorine-modified surface additive with hydrophobic and oleophobic structure 5, pigments and fillers 8 parts, defoamer 1.5 parts. The coating is prepared by using the preparation method provided by the invention.

Embodiment 2

[0044] Polymer emulsion 50, methyl methacrylate 10, butyl acrylate 9, isooctyl acrylate 5, di-n-butyl maleate 5, hydroxyethyl acrylate 0.6, sodium dodecyl sulfonate 0.3, potassium persulfate 0.1, sodium acetate 0.05, hydrophobic agent 1, fluorine-modified surface additive with hydrophobic and oleophobic structure 2, defoamer 1 part, dispersant 0.3 part, preservative 0.1 part. The coating is prepared by using the preparation method provided by the invention.

Embodiment 3

[0046] Polymer emulsion 65, methyl methacrylate 13, butyl acrylate 7, isooctyl acrylate 3, di-n-butyl maleate 6, hydroxyethyl acrylate 0.8, sodium dodecyl sulfonate 0.6, potassium persulfate 0.2, sodium acetate 0.1, hydrophobic agent 7, fluorine-modified surface additive with hydrophobic and oleophobic structure 0.5, pigment and filler 5 parts, defoamer 0.9 part, dispersant 1.2 part, thickener 2.0 part, preservative 0.02 part. The coating is prepared by using the preparation method provided by the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com