Insulating tube water channel leak detecting method

A technology for insulating pipes and pipes and waterways. It is applied in the direction of detecting the appearance of fluid at the leakage point and measuring the liquid tightness by using liquid/vacuum degree. Leakage signal source and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

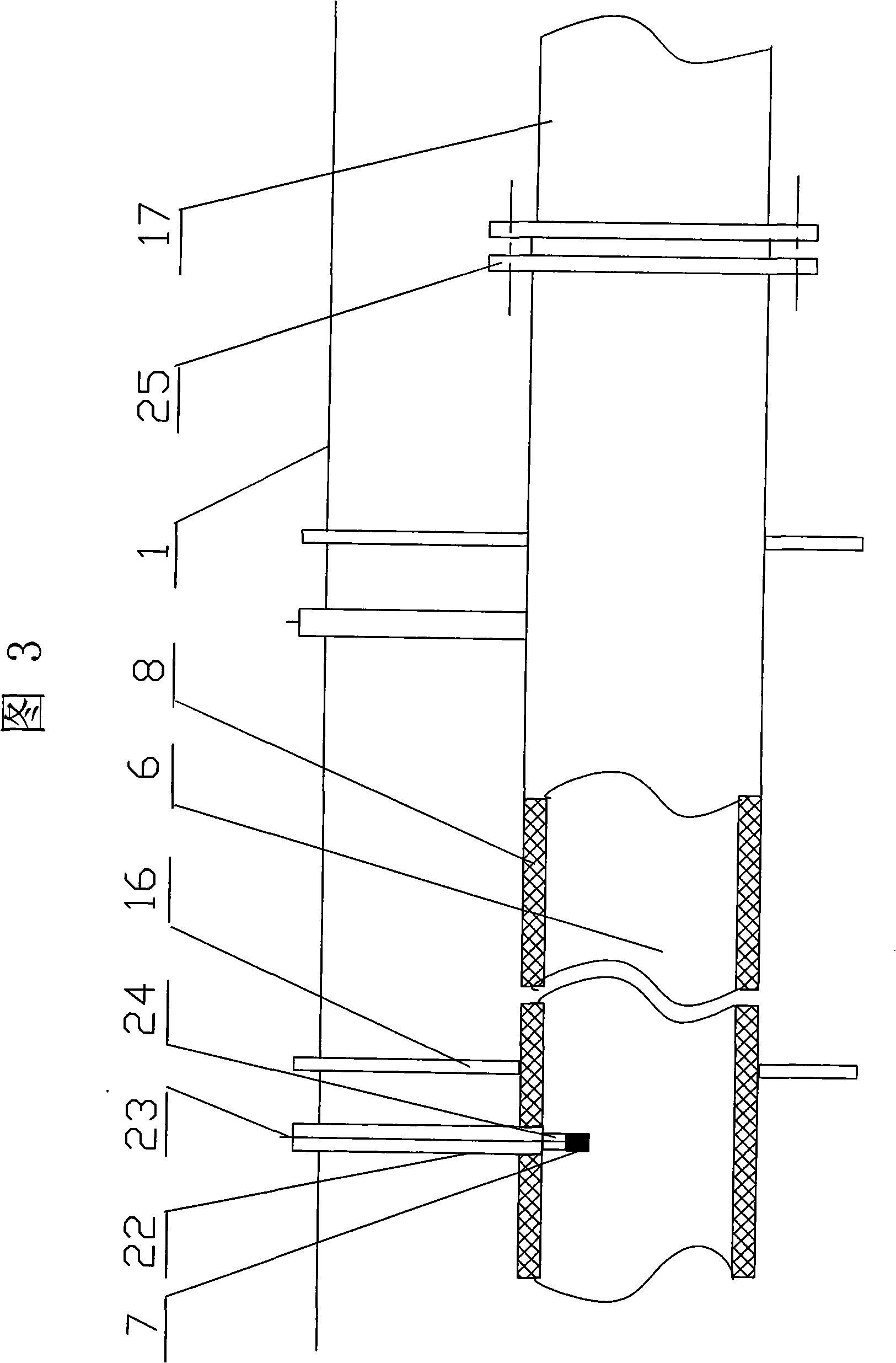

[0011] In Figure 1, 1 is the ground, 2 is the probe, 3 is the pulse line, 4 is the power line, 5 is the detection line, 6 is the pipe under test, 7 is the water contact in the probe, 8 is the insulating pipe wall, 9 Probe connection, 10 is the nut, 11 is the integrated lead wire, 12 is the bolt, 13 is the outer wall insulation valve, 14 is the detector, 15 is the ground wire, 16 is the ground stake, 17 is the ground conduction pipe, 18 is Transition insulating pipe, 19 is a valve well, 20 is a flange, and 21 is a flange sealing clip. Tap water is input from the ground conducting pipe 17 on the right side of the figure, flows through the transition insulating pipe 18, the outer wall insulating valve 13, and then reaches the measured pipeline 6, and a ground wire 15 is connected to the detector 14, which is in phase with the ground pile 16. connection, the tester 14 also outputs an integrated line 11, which enters the tested pipeline 6 through the flange sealing clip 21 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com