Electroplating poly carbonate (PC)/acrylonitrile butadiene styrene (ABS) alloy composition and preparation method thereof

A composition, ABS resin technology, applied in the fields of polymer blending and polymer molding processing, can solve the problems of carbon nanotubes with large specific surface area, poor compatibility, easy agglomeration, etc., to simplify the electroplating process, excellent electrical conductivity, The effect of promoting dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0033] The PC / ABS alloy composition of embodiment 1~3 is prepared through the following steps:

[0034] A, prepare materials by the components shown in Table 1 and parts by weight thereof;

[0035] b. Add the prepared raw materials into the mixing mixer for mixing;

[0036] c. Then, the mixture is blended and granulated by a twin-screw extruder to obtain electroplated PC / ABS alloy particles. The barrel temperature of the extruder is 250° C., and the screw speed is 500 rpm.

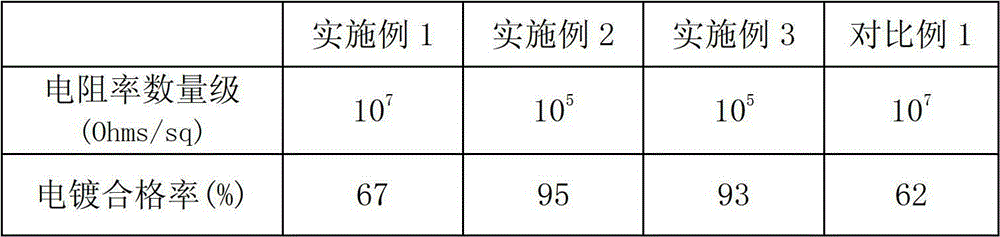

[0037] Table 1 Embodiment 1~3 and comparative example 1 each component and parts by weight

[0038]

[0039] In Table 1, the PC resin is PC201-22 from South Korea LG-DOW; the ABS resin is ABS8434 from Shanghai Gaoqiao Petrochemical; the carbon nanotubes are multi-walled carbon nanotubes from the Chinese Academy of Sciences Chengdu Organic Chemistry Co., Ltd. ~30nm; the compatibilizer is SAG-001 from Shanghai Rizhisheng New Material Development Co., Ltd; the antioxidant and lubricant are commerc...

Embodiment 4

[0041] The PC / ABS alloy composition of the present embodiment is prepared through the following steps:

[0042] A, prepare materials by the components shown in Table 2 and parts by weight thereof;

[0043] b. Add the prepared raw materials into the mixing mixer for mixing;

[0044] c. Then, the mixture is blended and granulated by a twin-screw extruder to obtain electroplated PC / ABS alloy particles. The barrel temperature of the extruder is 200-220° C., and the screw speed is 300-400 rpm.

[0045] The weight average molecular weight of the PC resin is 17000g / mol, and its glass transition temperature is 140°C;

[0046] The ABS resin is a graft copolymer composed of acrylonitrile-butadiene-styrene, its weight average molecular weight is 100000g / mol, wherein the weight percentage content of butadiene is 55%, and the weight percentage content of acrylonitrile is 15%, Styrene weight percent content is 30%;

[0047] The carbon nanotubes are multi-walled carbon nanotubes;

[0048...

Embodiment 5

[0052] The PC / ABS alloy composition of the present embodiment is prepared through the following steps:

[0053] A, prepare materials by the components shown in Table 2 and parts by weight thereof;

[0054] b. Add the prepared raw materials into the mixing mixer for mixing;

[0055] c. Then, the mixture is blended and granulated by a twin-screw extruder to obtain electroplated PC / ABS alloy particles. The barrel temperature of the extruder is 220-240° C., and the screw speed is 400-500 rpm.

[0056] The weight average molecular weight of the PC resin is 30000g / mol, and its glass transition temperature is 150°C;

[0057] The ABS resin is a graft copolymer composed of acrylonitrile-butadiene-styrene, its weight average molecular weight is 180000g / mol, wherein the weight percentage content of butadiene is 10%, and the weight percentage content of acrylonitrile is 20%, Styrene weight percent content is 70%;

[0058]The carbon nanotubes are multi-walled carbon nanotubes and single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com