Colorful ultraviolet resistant polyethylene electric cable material

An anti-ultraviolet and polyethylene technology, applied in the field of polyethylene cable materials, can solve the problems of easy fading, difficult coloring of colored cable materials, and low anti-ultraviolet performance, and achieve easy identification, excellent anti-ultraviolet performance, and excellent processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of yellow masterbatch: After fully mixing yellow toner with EVA resin, zinc stearate and EBS (ethylene bis stearamide), extrude and granulate at 180°C to make yellow masterbatch; The yellow toner: EVA resin: zinc stearate: the weight ratio of EBS is 45:50:3.5:1.5.

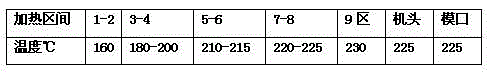

[0028] 2. Preparation of cable material: Take HDPE (HE6062): 70kg, LLDPE (7042) 24.5kg, yellow masterbatch 2.8kg, ultraviolet absorber (UV531) 2.0kg, polyethylene wax 0.4kg, antioxidant AT-10 0.1kg, AT-168 0.2kg, accurately metered and put into the high mixer, run for 2 minutes (note that first run at low speed for 1 minute, then run at high speed for 1 minute), the above-mentioned uniformly mixed raw materials are mixed, extruded, Cooling, dicing, drying and packaging.

Embodiment 2

[0030] 1. Preparation of black masterbatch: After fully mixing black toner with EVA resin, zinc stearate and EBS (ethylene bisstearamide), extrude and granulate at 180°C to make black masterbatch; The black toner: EVA resin: zinc stearate: the weight ratio of EBS is 45:50:3.5:1.5.

[0031] 2. Preparation of cable material: Take HDPE (HE6062): 70.3kg, LLDPE (7042) 25kg, black masterbatch 1.8kg, ultraviolet absorber (UV531) 2.2kg, polyethylene wax 0.4kg, antioxidant AT-10 0.1kg, AT-168 0.2kg, accurately metered and put into the high mixer, run for 2 minutes (note that first run at low speed for 1 minute, then run at high speed for 1 minute), the above-mentioned uniformly mixed raw materials are mixed, extruded, Cooling, dicing, drying and packaging.

Embodiment 3

[0033] 1. Preparation of blue color masterbatch: After fully mixing blue color powder with EVA resin, zinc stearate and EBS (ethylene bisstearyl amide), extrude pellets at 180°C to make blue color masterbatch; The toner: EVA resin: zinc stearate: the weight ratio of EBS is 45:50:3.5:1.5.

[0034] 2. Preparation of cable material: Take HDPE (HE6062): 68.5kg, LLDPE (7042) 26kg, blue masterbatch 2.4kg, ultraviolet absorber (UV531) 2.4kg, polyethylene wax 0.4kg, antioxidant AT-10 0.1kg, AT-168 0.2kg, accurately metered and put into the high mixer, run for 2 minutes (note that first run at low speed for 1 minute, then run at high speed for 1 minute), the above-mentioned uniformly mixed raw materials are mixed, extruded, Cooling, dicing, drying and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com