Paroxetine hydrochloride compound and synthetic method thereof

A technology of paroxetine hydrochloride and paroxetine methyl, which is applied in the field of medicine, can solve problems such as unfavorable removal of organic solvents, poor stability of chloroformic acid-α-chloroethyl ester, complicated operation, etc., and achieve mild production conditions and good stability , the effect of high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

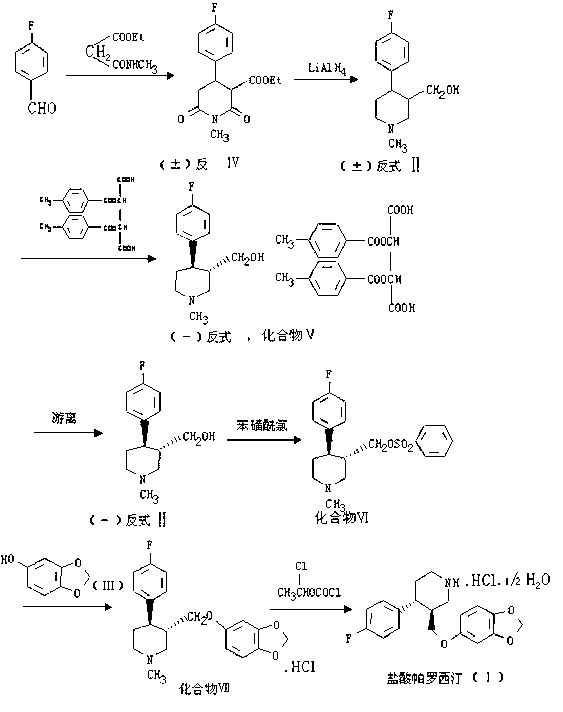

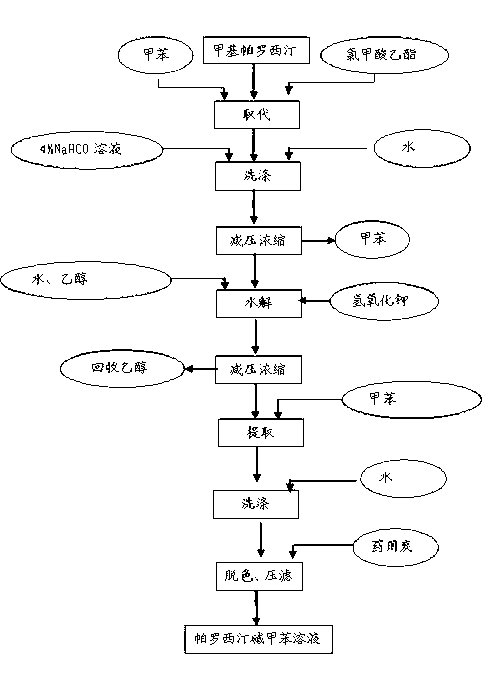

[0030] Synthetic process and refining method of paroxetine hydrochloride

[0031] 1) Preparation of crude paroxetine hydrochloride:

[0032] Such as figure 2 As shown, add 20 kg of N-methylparoxetine into 290 kg of toluene, stir, add ethyl chloroformate toluene mixture dropwise at room temperature, after the addition, stir for 30 minutes, heat up to 60-70 ° C, keep stirring for 4- After 6 hours (TLC detected that the reaction was complete, petroleum ether: ethyl acetate = 3:1), the organic layer was washed with water and aqueous sodium bicarbonate solution respectively, the water layer was separated, and the toluene was concentrated under reduced pressure to obtain a viscous substance.

[0033] N-methylparoxetine, source: Linhai Jinqiao Chemical Factory

[0034]

[0035] Add 700kg of ethanol to the residue, add 70.0Kg of potassium hydroxide, and heat up and reflux for 20-25 hours (about 80°C) (TLC test shows that the reaction is complete, if the reaction is too slow, add...

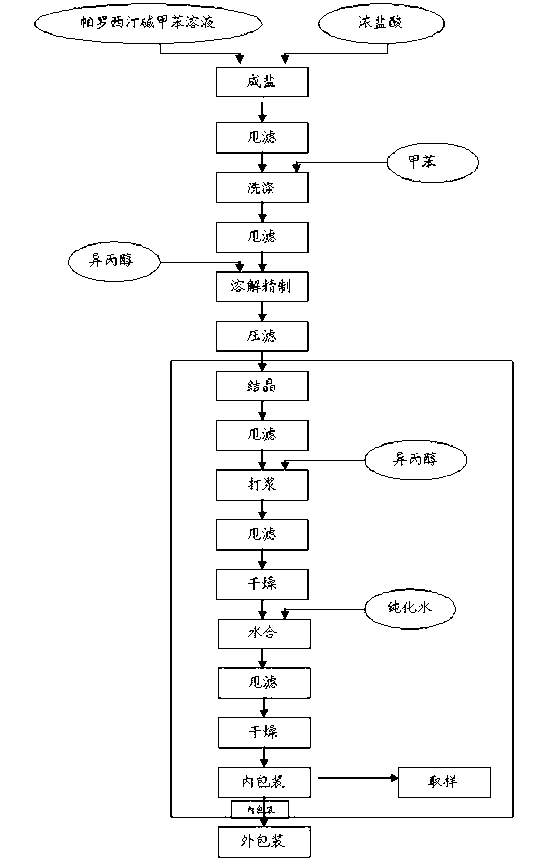

Embodiment 1 3

[0043] The stability situation of embodiment 1 three batches of samples is as follows:

[0044] Stability inspection items: selected according to the key inspection items stipulated in the above guiding principles and the properties of this variety, mainly including appearance, pH, moisture, related substances, and content.

[0045] Inspection basis: According to the 2010 edition of the Pharmacopoeia standard of paroxetine hydrochloride

[0046] Sample: three batches of 100401, 100402, and 100403 produced in Example 1.

[0047] accelerated test

[0048] Test method: Take this product to simulate the packaging of the marketed drug, and place it at 40 ° C ± 2 o C Place it under the condition of relative humidity RH75%±5% for 6 months. Samples were taken at 0, 1, 2, 3 and 6 months, and the indicators measured were compared with the samples at 0. The test results are shown in Table 1.

[0049] The accelerated test was carried out for 6 months, and the test results showed tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com