Preparation method of heat-resistant foamed microcapsule

A technology of microcapsules and heat resistance, which is applied in the field of preparation of heat-resistant foamed microcapsules, can solve the problems that the crude product contains gel groups, the polymer shell is not elastic, and cannot be miscible with alkaline substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

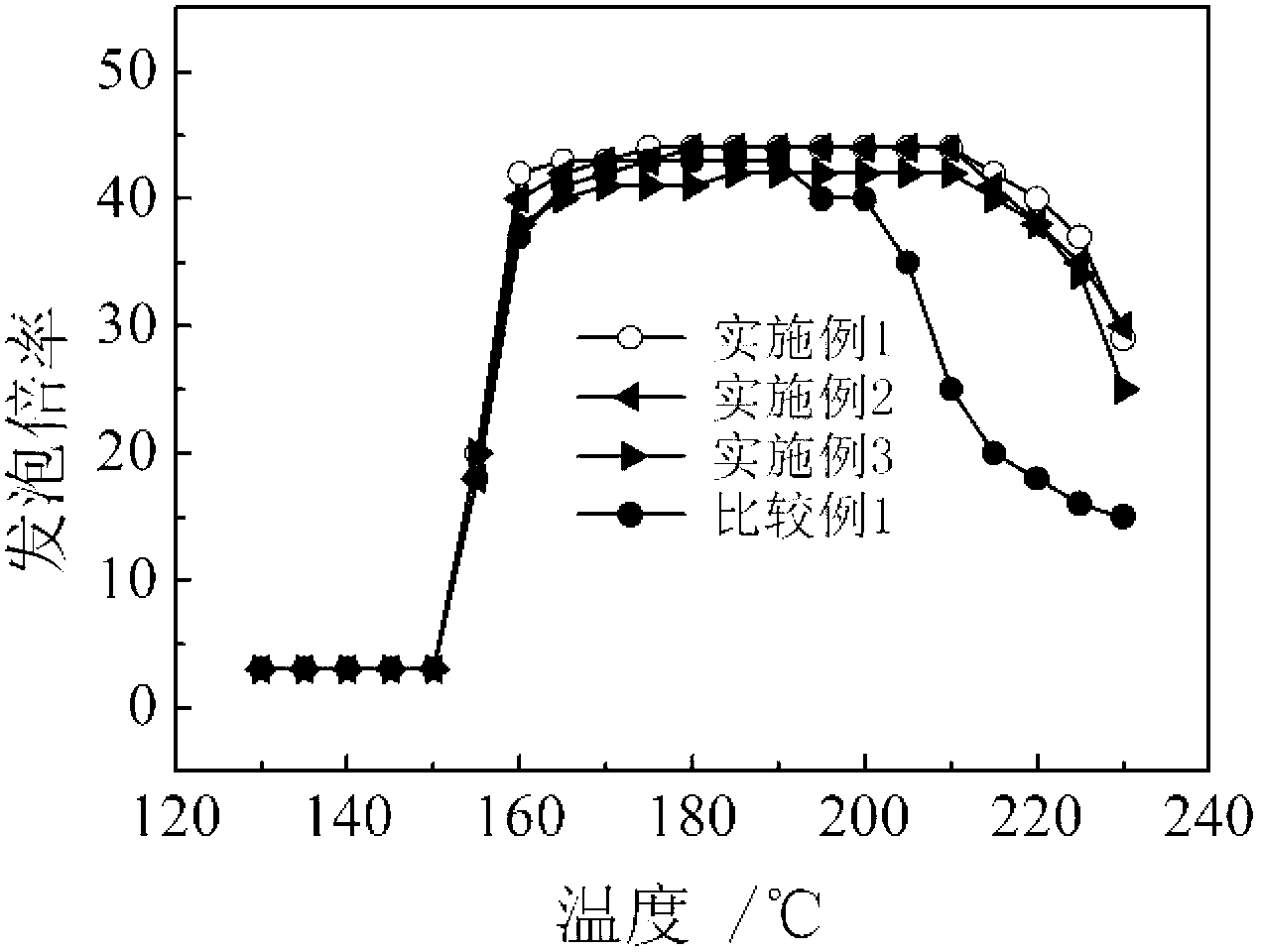

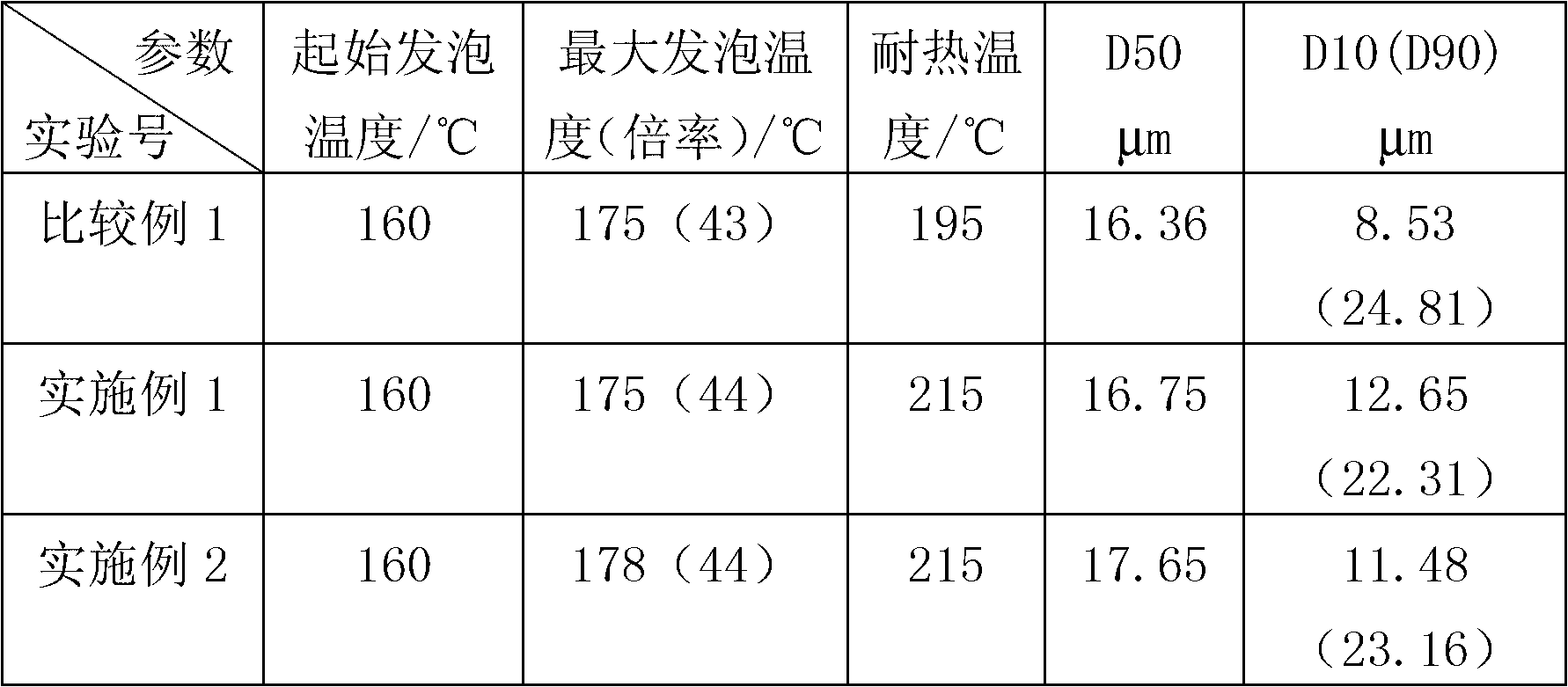

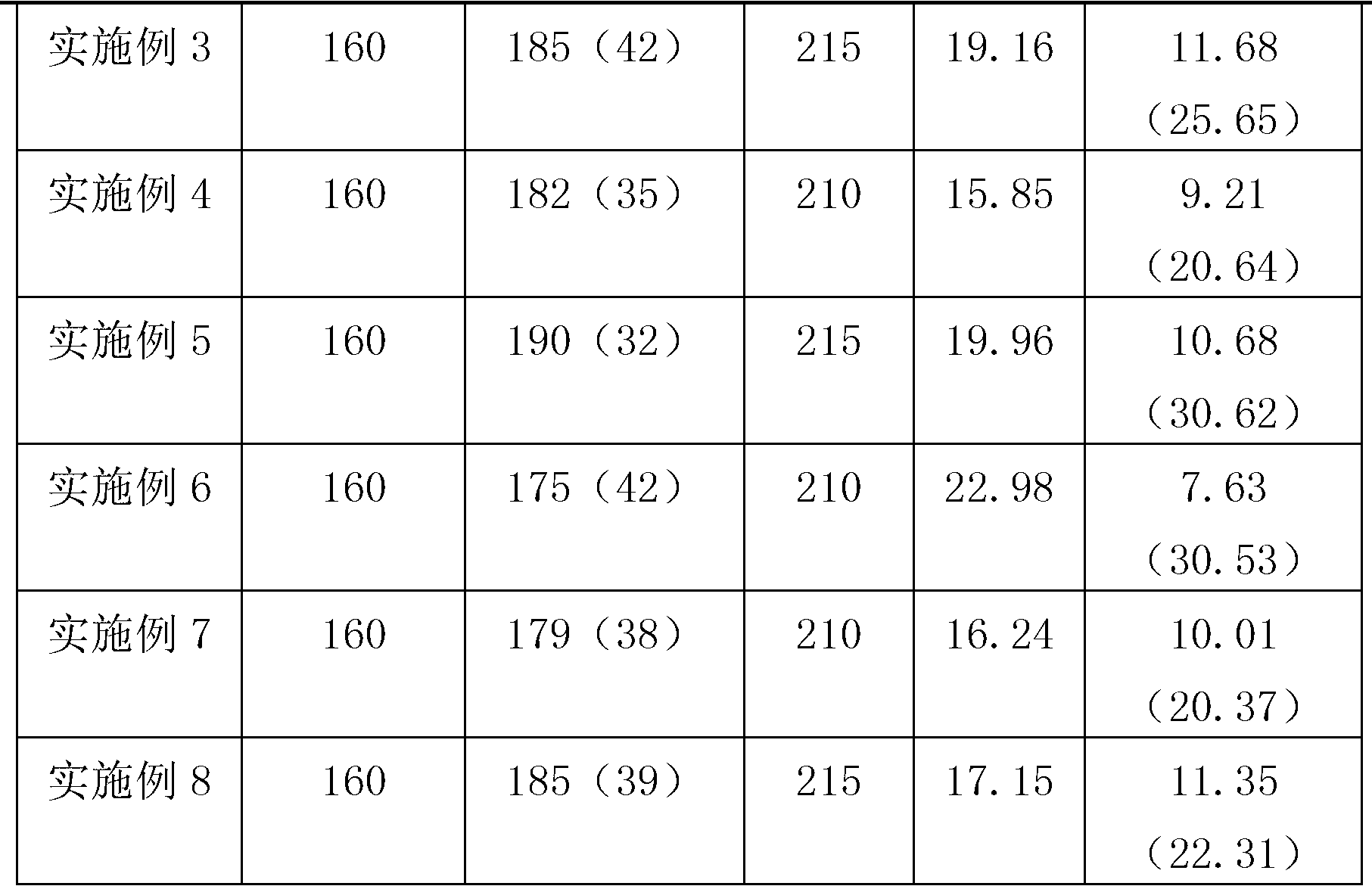

Examples

preparation example Construction

[0031]According to the above technical ideas, the present invention provides a method for preparing heat-resistant foamed microcapsules, which is formed by suspension polymerization with acrylonitrile monomer polymer as the capsule wall and low-boiling alkane foaming agent as the core material. Include the following steps:

[0032] (1) Generation of the main dispersant, the main dispersant is a silane coupling agent modified silica sol, the generation method is to add silica sol in a reaction kettle with reflux and stirring, and drip the organosilicon coupling agent at a constant temperature to react. Dispersant;

[0033] (2) The generation of suspoemulsion, the water-based mixed liquid and the oil-phase mixed liquid are dispersed into small droplets under a high-speed homogenizer to obtain a suspoemulsion, wherein the aqueous mixed liquid is composed of a dispersant, a pH regulator, an inorganic salt, and a deionized The water is mechanically stirred in a certain proportion;...

Embodiment 1

[0056] Silane coupling agent modified silica sol: In a 250mL flask equipped with reflux and stirring, add 100g of silica sol (solid content 30%) and raise the temperature to 60°C, and drop in 1.0g of methacryloxytrimethoxy Base silane A-174 organic silicon coupling agent, heat preservation and stirring for 6 hours, and finally add water to dilute to an aqueous solution with an effective solid content of 30% for later use.

[0057] Water phase mixed solution: Take 600g of distilled water and add it to a 1000mL plastic beaker, add 150g of sodium chloride, 16g of modified silica sol, 2.4g of polyvinylpyrrolidone, etc. under mechanical stirring, and add dilute sulfuric acid dropwise after stirring to adjust the solution The pH value is 1.5 to obtain an aqueous emulsion.

[0058] Oil phase mixture: Add 150g of acrylonitrile, 50g of methacrylonitrile, and 20g of isobornyl methacrylate cooled in the refrigerator into a 300mL plastic beaker under ventilated conditions, add dropwise hy...

Embodiment 2

[0061] The difference from Example 1 is:

[0062] Silane coupling agent modified silica sol: the organosilicon coupling agent is vinyltrimethoxysilane (A-171), and the dropping amount is 1.4g.

[0063] Water-phase mixed solution: 24g of modified silica sol, 4g of polyvinylpyrrolidone, adjust the pH value of the solution to 2 to obtain an aqueous emulsion.

[0064] Oil phase mixture: the amount of each substance is as follows, 130g acrylonitrile, 70g methacrylonitrile, 18g isobornyl methacrylate, dropwise add 2g hydroxypropyl methacrylate, 3.0g dipropylene glycol diacrylate, and then add azo 2.2 g of diisobutyronitrile, 25 g of pentane, and 35 g of isohexane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com