Preparation method of infrared radiation ceramic powder in spinel-silicate multi-phase composite system

A technology of infrared radiation and ceramic powder, which is applied in the field of infrared radiation materials, can solve the problems of complex preparation process of infrared radiation materials, unsatisfactory thermal shock resistance, and reduced infrared radiation performance of materials, so as to achieve excellent infrared radiation performance and shorten The production cycle and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

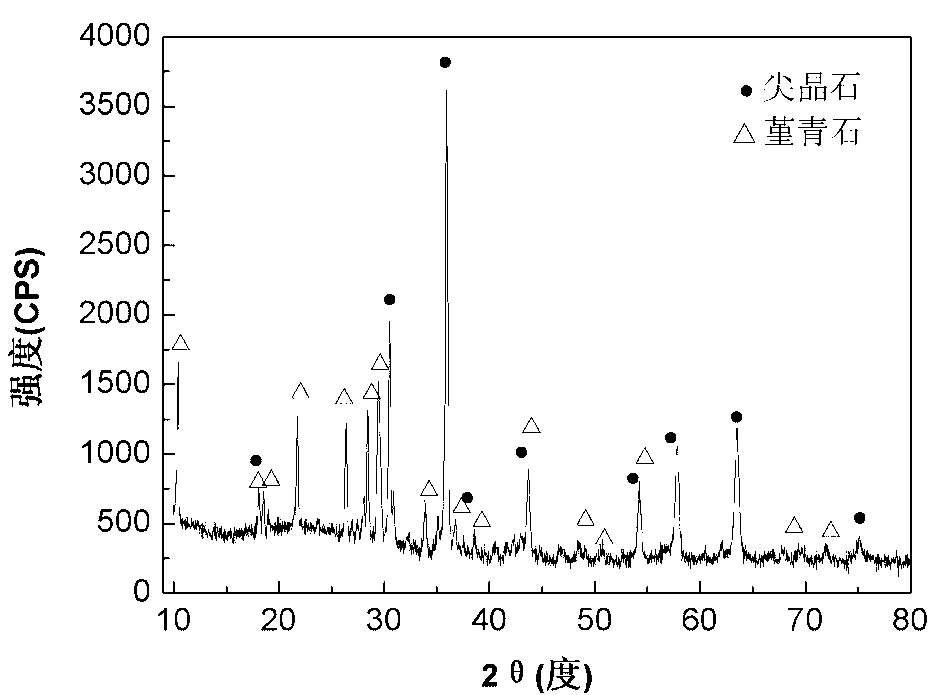

[0032] By mass ratio: 20%Fe 2 o 3 , 12%MnO 2 , 2.4%CuO, 2.4%Mo 2 o 3 , 2%V 2 o 5 , 1.2%WO 3 , 20%Al 2 o 3 , 25.1%SiO2 2 , 10%MgO, 1.5%BaO, 1.4%CaO, 1% glass powder and 1%B 2 o 3 Carry out batching, the raw material composition of described glass powder is: 65%SiO 2 , 15%Al 2 o 3 , 5%CaO, 3%BaO, 8%MgO, 2%TiO 2 , 2% ZnO, the above ingredients are ball milled, mixed, dried and pressed into a block body; in the process of firing the above block body, it is first heated to 950 ° C for 4 hours to form a spinel type solid solution, and then continue to heat up to 1200 ° C for 2 hours to form silicate minerals, so that the spinel solid solution and silicate minerals are multi-phase compounded to form a black sintered body with a multi-phase composite structure; after crushing and crushing, Pass through a 320-mesh sieve to prepare spinel-silicate multi-phase composite system ceramic powder with a particle size of less than 47 μm.

[0033] The obtained spinel-silicate mu...

Embodiment 2

[0036] By mass ratio: 11%MnO 2 , 10%Co 2 o 3 , 3%NiO, 5%WO 3 , 50%Al 2 o 3 , 9%SiO2 2 , 6%TiO 2 , 3% CaO, and 3% glass powder for batching, and the raw material composition of glass powder is 65% SiO 2 , 15%Al 2 o 3 , 5%CaO, 3%BaO, 8%MgO, 2%TiO 2 , 2% ZnO, the above ingredients are ball milled, mixed, dried and pressed into a block green body; in the firing preparation process of the above green body, it is first heated to 800°C for 6 hours, and then continues to heat up to 1300°C for heat preservation 6 hours; crushing and pulverizing, passing through a 200-mesh sieve to prepare a spinel-silicate multi-phase composite system ceramic powder with a particle size of less than 74 μm.

[0037] The normal full-band emissivity of the spinel-silicate multiphase composite ceramic powder is 0.90, the emissivity of the 8μm~25μm band is 0.94, the emissivity of the 8μm~14μm band is 0.92, and the radiation of the 14μm~25μm band The rate is 0.94.

Embodiment 3

[0039] By mass ratio: 6%Fe 2 o 3 , 12%CuO, 4%Mo 2 o 3 , 5%V 2 o 5 , 14%Al 2 o 3 , 50%SiO2 2 , 3%MgO, 3%BaO, 3%B 2 o 3 For batching, the above ingredients are ball milled, mixed, dried and pressed into a block-shaped green body; during the firing and preparation of the above-mentioned green body, first heat to 950°C for 2 hours, and then continue to heat to 1200°C for 8 hours and then through crushing and pulverizing, passing through a 400-mesh sieve to prepare a spinel-silicate multi-phase composite system ceramic powder with a particle size of less than 38 μm.

[0040] The normal full-band emissivity of the spinel-silicate multiphase composite ceramic powder is 0.89, the emissivity of the 8μm~25μm band is 0.90, the emissivity of the 8μm~14μm band is 0.90, and the radiation of the 14μm~25μm band The rate is 0.93.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com