Large-size impeller processing technique in precise casting

A technology of precision casting and processing technology, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. Shell cycle, reduce labor intensity, improve the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The processing technology of medium and large impellers in precision casting of the present invention comprises the following steps:

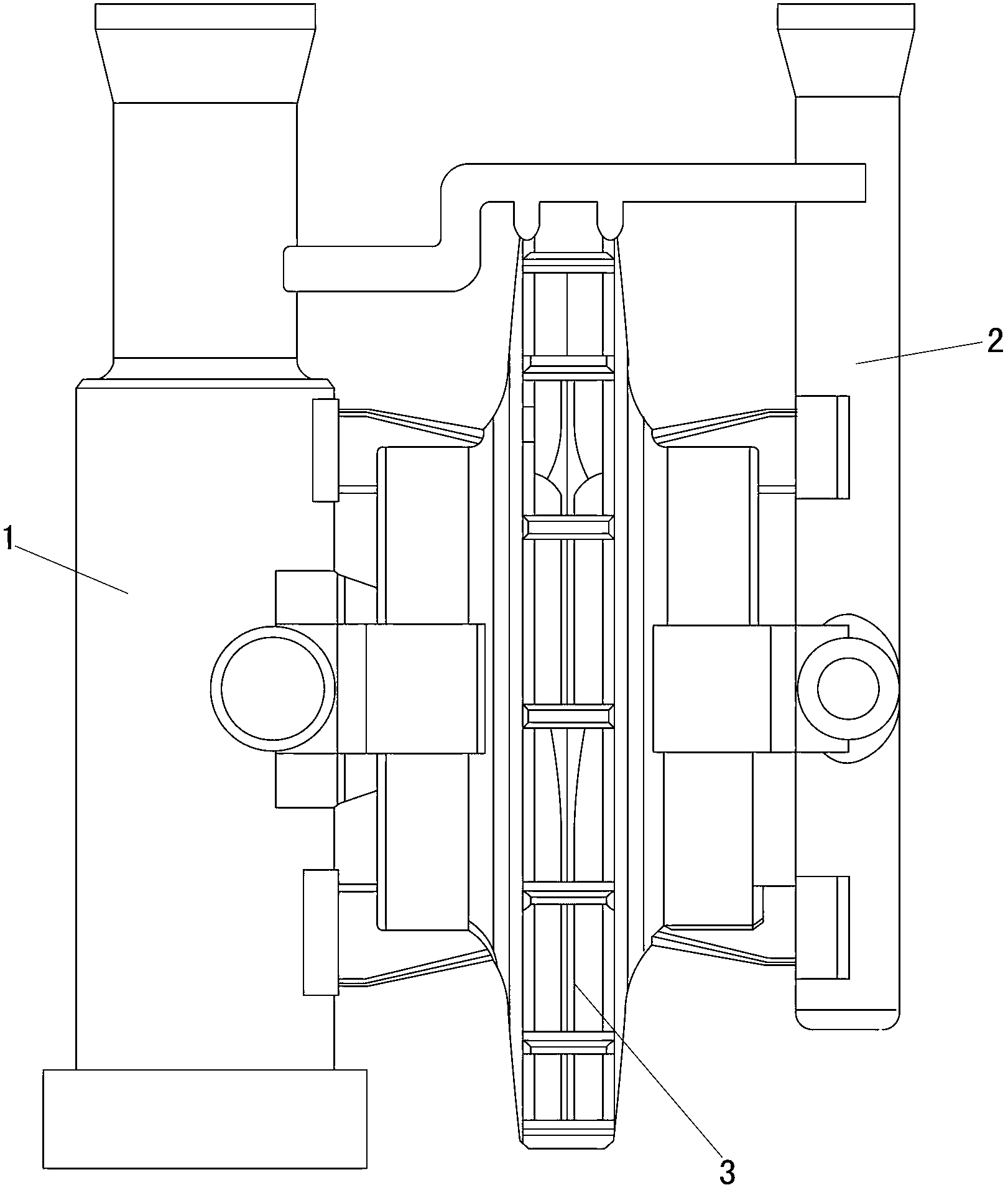

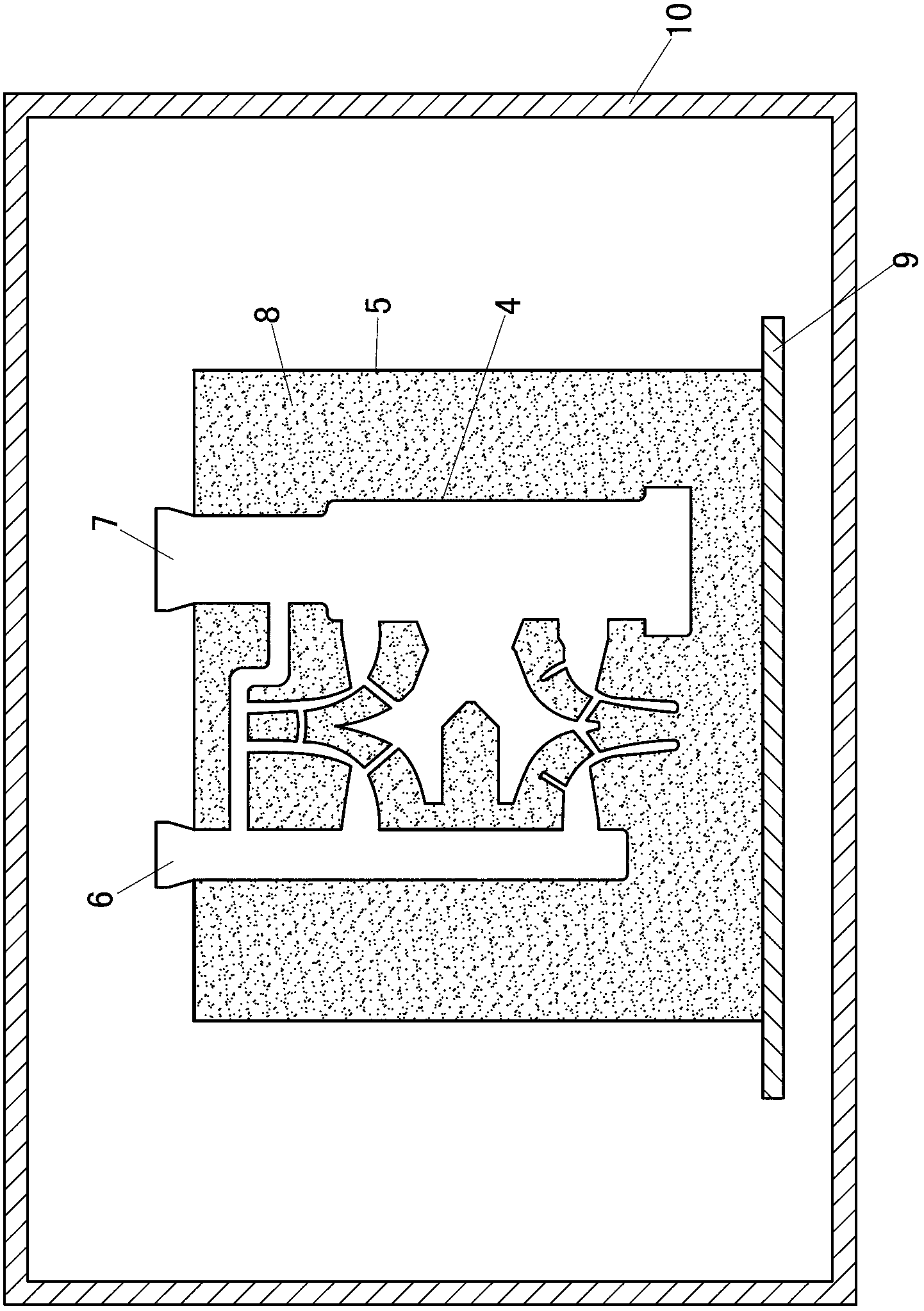

[0016] (1) combination figure 1 As shown, using plastic foam as a model, the left gating system foam mold 1, the right gating system foam mold 2 and the casting foam mold 3 located between the left gating system foam mold 1 and the right gating system foam mold 2 are bonded together, Form a module, then coat 4-6 layers of refractory material on the outer surface of the module to make a shell, and bake the module coated with refractory material through a roasting furnace to make the foam mold 1 of the left gating system and the foam mold of the right gating system Mold 2 and Casting Foam Mold 3 burnt out, refer to figure 2 As shown, obtain the impeller fine-cast white ceramic thin shell 4 with cavity, the thickness of this thin shell 4 is 5-8mm;

[0017] (2) combine figure 2 As shown, the thin shell 4 prepared in step (1) is put into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com