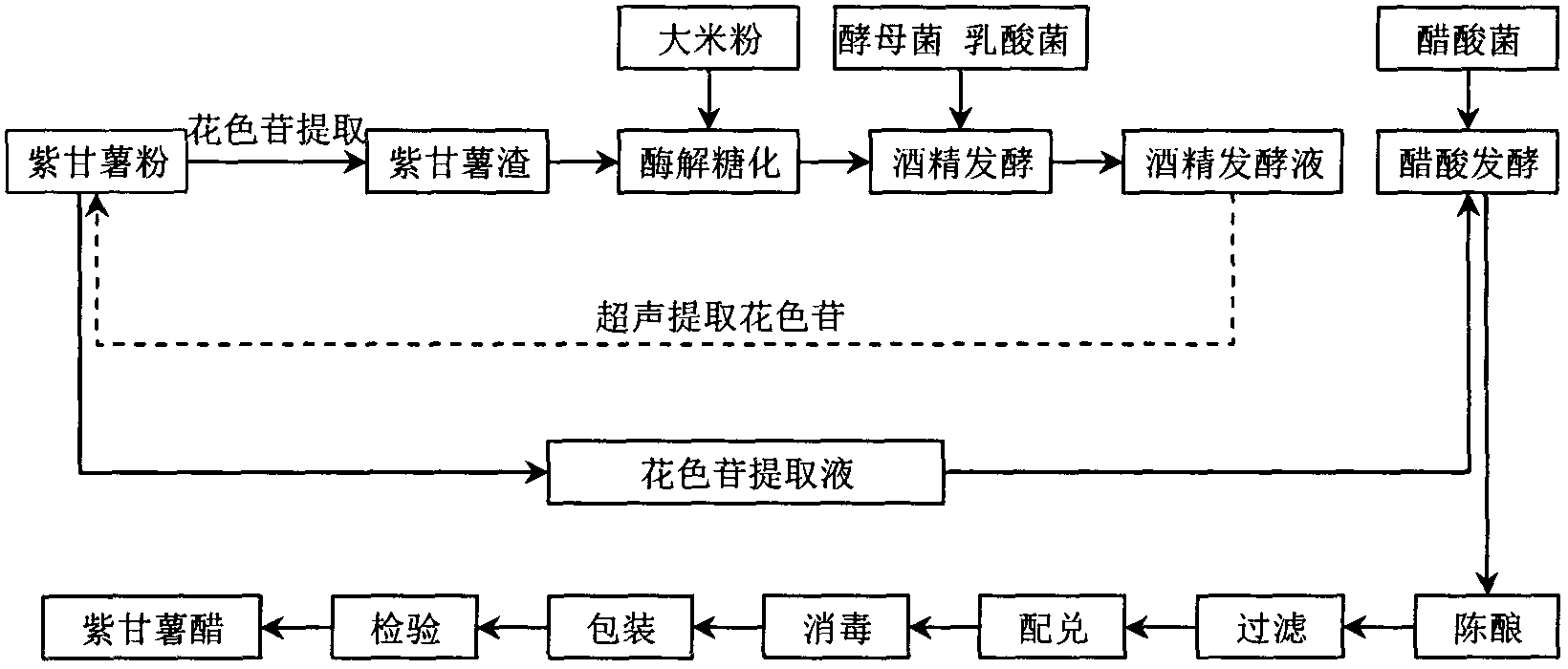

Purple sweet potato vinegar and brewing process thereof

A purple sweet potato and process technology, applied in the preparation of vinegar, microorganisms, biochemical equipment and methods, etc., can solve the problems of easy degradation of anthocyanins, low retention rate, strong pungent taste, and low non-volatile acid content, and achieve production Conditions are easy to control, irritating odor is reduced, and the effect of high clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

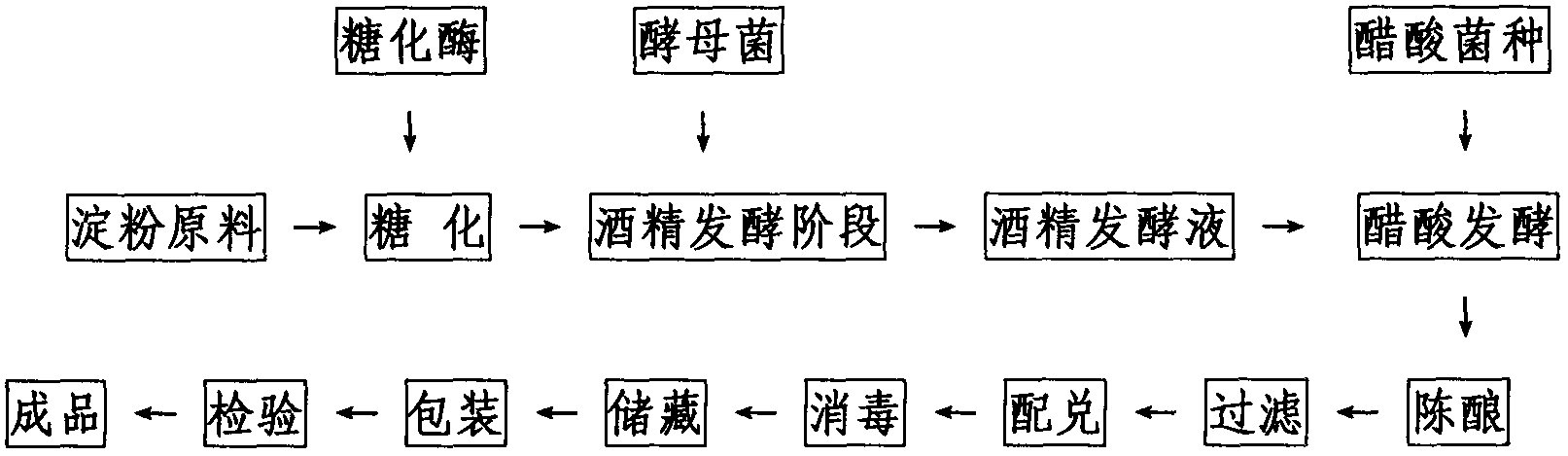

Method used

Image

Examples

Embodiment 1

[0050] Wash the purple sweet potato, remove the rotten part, cut it into 3-5mm thin slices after drying, dry it in a hot air drying oven at 50°C, spread it out to cool to room temperature, crush it, and pass it through a 60-mesh sieve (water content 6.4%); rice Crush after removing impurities, and pass through a 60-mesh sieve (moisture content 14.3%).

[0051] In the first extraction of purple sweet potato anthocyanins, 2% citric acid aqueous solution was used to ultrasonically extract anthocyanins. The ultrasonic extraction conditions are: solid-liquid ratio 1:5, power 350W, temperature 45°C, extraction time 30min. After the extraction, the purple sweet potato residue (water content 159.3%) was obtained by filtration, and then saccharified according to the following method; after that, the purple sweet potato anthocyanins were extracted by ultrasonication from the alcoholic fermentation broth.

[0052] Purple sweet potato dregs (dry basis), mixed according to the ratio of ma...

Embodiment 2

[0056] The preparation of purple sweet potato powder is with embodiment 1.

[0057] The first extraction of the purple sweet potato powder anthocyanin extract was the same as in Example 1, and the ultrasonic extraction conditions were: solid-liquid ratio 1:10g / mL, power 300W, temperature 50°C, and extraction time 35min. The saccharification step is the same as in Example 1.

[0058] Purple sweet potato dregs saccharification liquid and rice saccharification liquid were mixed according to the ratio of 1:0.5 (v / v), added 0.3% (m / v) active dry yeast and 15% (v / v) lactic acid bacteria seed liquid, placed in Ferment at 30°C for 6 days, stir once every 12 hours for 3 days before fermentation, and then ferment in a sealed container. After the fermentation is over, filter to get the supernatant. Anthocyanins were extracted according to the ultrasonic extraction method described in Example 1. After the extraction was completed, the supernatant was taken from natural sedimentation and...

Embodiment 3

[0060] The preparation of purple sweet potato powder is with embodiment 1.

[0061] The first extraction of purple sweet potato powder anthocyanin extract was the same as in Example 1, and the ultrasonic extraction conditions were: solid-liquid ratio 1:15g / mL, power 250W, temperature 55°C, extraction time 25min. The saccharification step is the same as in Example 1.

[0062] Purple sweet potato dregs saccharification liquid and rice saccharification liquid were mixed according to the ratio of 1:2 (v / v), added 0.4% (m / v) active dry yeast and 10% (v / v) lactic acid bacteria seed liquid, placed in Ferment at 32°C for 5 days, stir once every 12 hours for 3 days before fermentation, and then ferment in a sealed container. After the fermentation is over, filter to get the supernatant. Anthocyanins were extracted according to the ultrasonic extraction method described in Example 1. After the extraction was completed, the supernatant was taken from natural sedimentation and inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com