Soluble rosinyl polyimide, film and preparation method of film

A rosin-based polyimide, soluble technology, applied in the field of material science, can solve problems such as the influence of heat resistance, and achieve the effect of simple preparation process, excellent solubility and thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

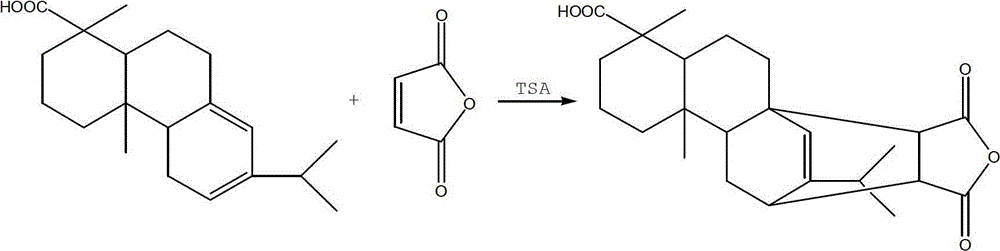

[0045] Preparation of maleopimaric anhydride:

[0046] Add 100 parts by weight of pimaric acid, 17 parts by weight of maleic anhydride, 3.33 parts by weight of p-toluenesulfonic acid (TSA), 55 parts by weight of ice After the acetic acid, pass nitrogen gas for 15 minutes to make the reactants exist in the environment under the protection of nitrogen gas. Slowly heat to 110°C. After the material is basically melted, turn on the stirrer at a stirring speed of 50r / min, and continue to heat up evenly. Adjust the reaction temperature in the bottle by adjusting the amount of acetic acid in the reaction bottle. After the temperature in the reaction bottle rises to After 180° C., keep this temperature for 4 hours, then lower the temperature. When the temperature in the reaction bottle drops to 110° C., add 210 parts by weight of glacial acetic acid and stir evenly. When the material was lowered to room temperature, it was further cooled with ice water, and the white crystalline crude...

Embodiment 1

[0065] A kind of soluble rosin-based polyimide, its molecular formula is as follows:

[0066]

[0067] In the formula, x=1-200, y=1-60.

[0068] The preparation method of present embodiment soluble rosin-based polyimide film is as follows:

[0069] (1) Weigh 1.069g (0.0099mol) of p-phenylenediamine monomer and 48.0mL of N,N-dimethylacetamide, and add them into a 150mL three-necked flask. Introduce nitrogen for 10 minutes, stir at room temperature at a high speed of 300r / min until it is completely dissolved, continue to infiltrate nitrogen for 30 minutes to ensure that water vapor, oxygen, etc. are completely excluded, and maintain the reaction system at room temperature. Maleopimaric acid dianhydride and 0.218g (0.001mol) 1,2,4,5-pyromellitic dianhydride were put into the three-necked bottle in 3 batches, and the interval between two feedings was 10 minutes. After the feeding was completed, the reaction was continued for 2 hours under a nitrogen atmosphere to obtain a pol...

Embodiment 2

[0072] A kind of soluble rosin-based polyimide, its molecular formula is as follows:

[0073]

[0074] In the formula, x=1-200, y=1-60.

[0075] The preparation method of present embodiment soluble rosin-based polyimide film is as follows:

[0076] (1) Weigh 1.027g (0.0095mo) of p-phenylenediamine monomer and 40.7mL of N-methyl-2-pyrrolidone into a 150mL three-necked flask. Nitrogen was introduced for 10 minutes, stirred at a high speed of 300 r / min at room temperature until it was completely dissolved, and nitrogen was continued for 30 minutes to ensure that water vapor, oxygen, etc. were completely excluded, and the reaction system was kept at room temperature. Weighed 5.904g (0.008mol ) maleopimaric acid dianhydride and 0.436g (0.002mol) 1,2,4,5-pyromellitic dianhydride were put into the three-necked bottle in 3 batches, and the interval between two feedings was 10 minutes. After the feeding was completed, the reaction was continued for 2 hours under a nitrogen atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com