Novel conductive glass fiber material and manufacturing method thereof

A technology of conductive glass fiber and glass fiber, which is applied in the field of conductive glass fiber material and its manufacture, to achieve the effects of mild reaction conditions, excellent conductivity and transparency, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

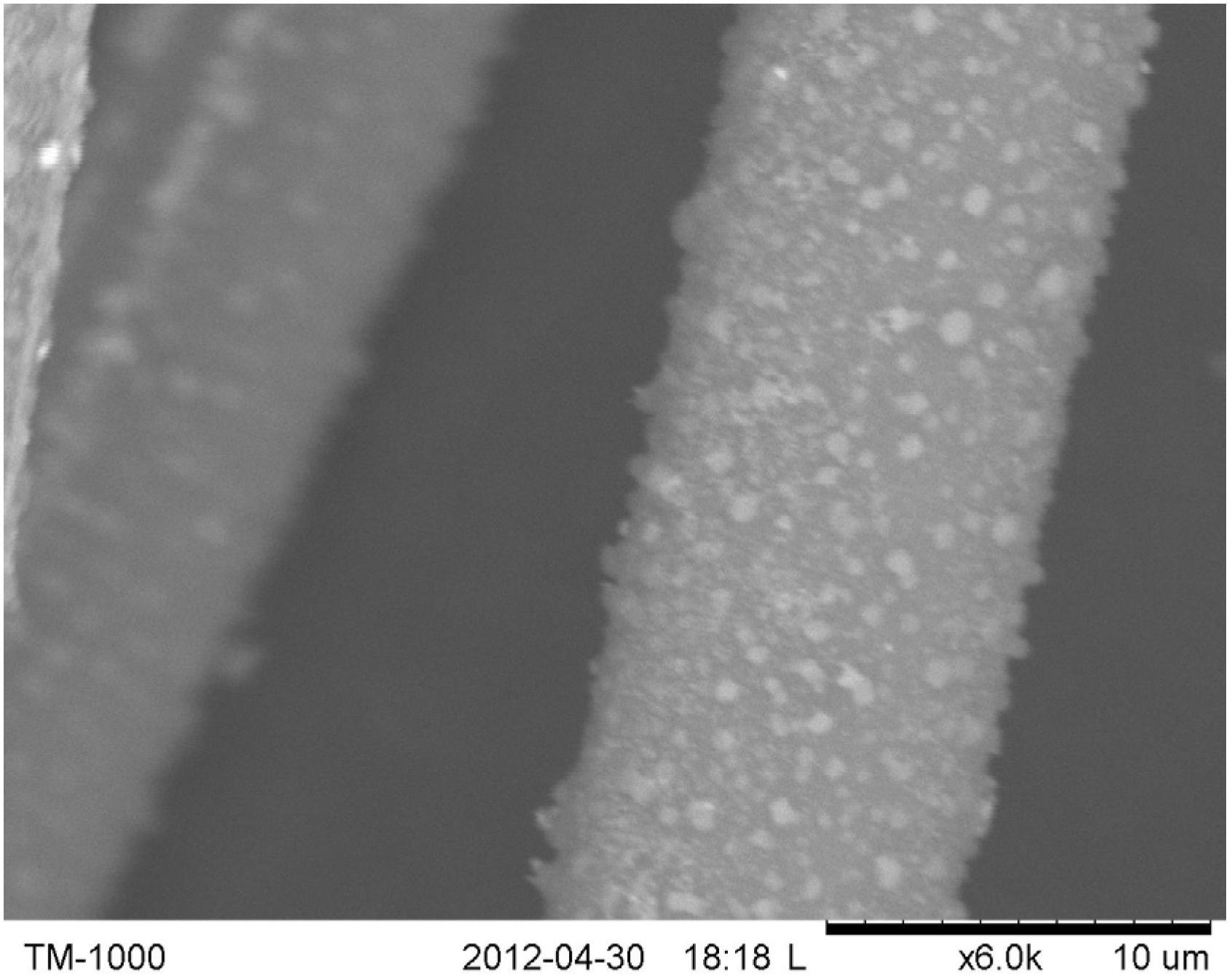

[0027] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

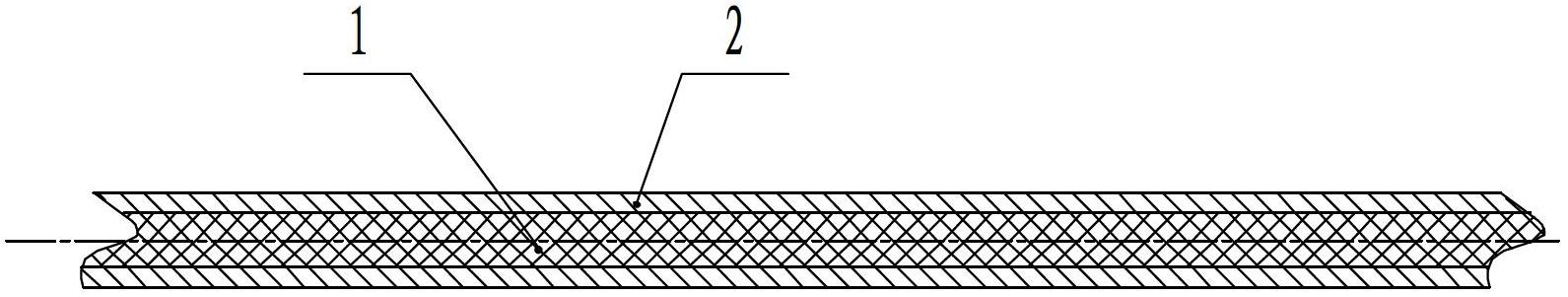

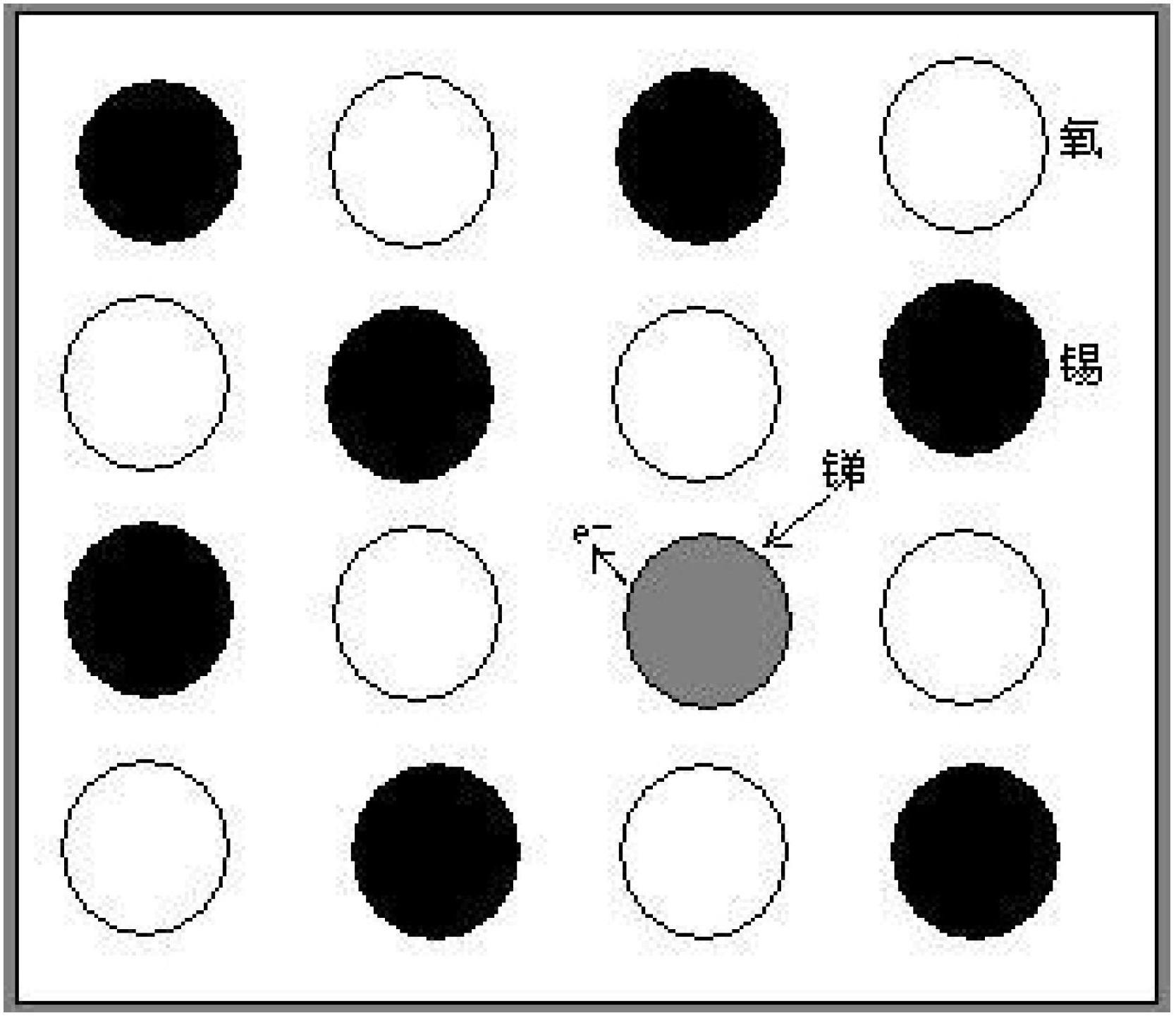

[0028] Such as figure 1 As shown, the present invention includes a glass fiber 1, and an antimony-doped tin oxide conductive sol-gel coating layer 2 with a uniform thickness is provided on the outer surface of the glass fiber 1;

[0029] The preparation method of the present invention adopts the following process steps:

[0030] Step 1: Pre-treat the glass fiber with glass fiber 1 cleaning and drying technology: put the glass fiber 1 in acetone for 3 times of ultrasonic treatment, 15 minutes each time, and then put it in absolute ethanol for 3 times of ultrasonic treatment, each time 10 minutes for each treatment, and finally placed in deionized water for ultrasonic treatment 2 times, 10 minutes each time, put the clean glass fiber 1 into a hot air drying oven until dry;

[0031]Step 2: Prepare antimony-doped tin oxide sol by sol-gel method, weigh tin tetrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com